8 February 1941. Bardia, Libya.

allanpcameron

Donor

8 February 1941. Bardia, Libya.

The A10 tanks of 1st and 6th Battalion RTR, and the A9 tanks of 7th and 8th Hussars had picked their way carefully back over the tracks of Cyrenaica to Bardia. 7th Armoured Division’s RAOC workshops had taken over Italian installations which allowed a fairly efficient processing of vehicles. While the rest of the Division had been in action, the wrecked tanks had been gathered from various points and entirely stripped of anything of value. This added to the supply of spare parts.

The tanks went through what in other situations might be described as triage. The tanks that were literally on their last legs, usually they had been towed back to Bardia, were put to one side. The RAOC Officer in Command marked them to be shipped back to the Delta to the main depots and workshops. They would need a lot of man-hours to get them fixed up, and would drain the stores at Bardia of vital parts.

The second lot of tanks were those with known defects. Each tank was inspected and a report of what was needed to bring it up to full operations was noted. The question was whether or not the defects could be fixed from the existing stores and how long it would take. If it could be done with the resources at hand and in a timely manner, they were put to one side and would be worked on. Those needing more profound work would join the shipment back to the Delta.

All the other tanks, the Division’s ‘runners’, tended to be overdue on their servicing needs and there were jobs beyond the capability of their own crews that needed time in the workshop. These were the first to be worked on. All four Regiments had been together a long time, and were used to mucking in with the fitters and mechanics of the Divisional workshops. The objective was getting as many of the ‘runners’ up to full capability. If possible, General Creagh wanted at least one Regiment’s worth of each type ready for action, just in case.

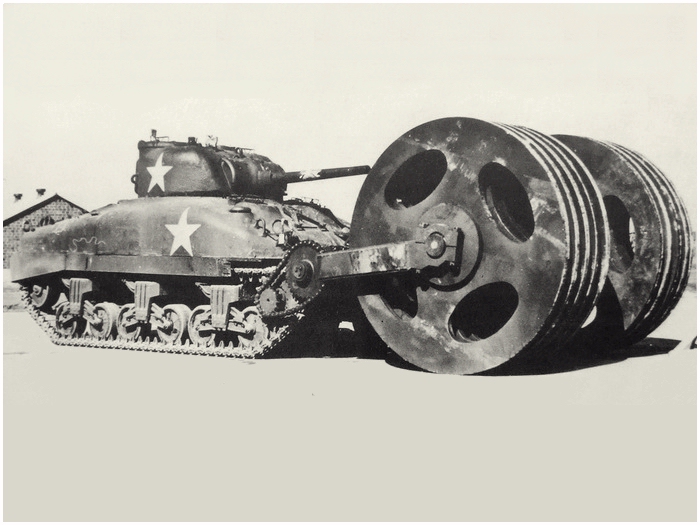

With word coming through that the Division was to be re-equipped with Valiant Mark I Infantry Tanks, the men of the four regiments started working with the 44th & 48th Bn RTR to become familiar with the new type of tank. For the men of the two Royal Tank Regiment Battalions swapping an A10 for a Valiant was like an upgrade. For much the same speed, they were getting vastly more protection, range and comfort. The same 2-pdr gun meant that it wasn’t a complete upgrade, but so far, the 2-pdr had proven itself a useful tool. The Hussars were more conflicted. The speed difference between the A9 and Valiant wasn’t that vast, and if pushed for honesty, there weren’t that many times that the A9 had been driven at its supposed top speed. The increased armour was certainly a big change. The Italian anti-tank guns were a real threat to the A9, the Valiant would be all but invulnerable. The problem was that the tank was the Infantry Tank Mark III, not a cruiser tank. Somehow it felt that their cavalry heritage was being lost using a tank designed to support the foot-infantry, rather than the dashing efforts of reconnaissance, screening and exploiting.

In the days that followed, as the men worked hard, and had their stories to tell of the victories over the Italians. Generally, there was a very positive mood in 7th Armoured Division about the new tanks they were going to get. There was much to learn about diesel engines and a suspension system that felt like a step backwards over the ‘slow motion’ of the A9 and A10. There was a lot of discussion about the relative merits of one kind of tank against another, and some had feared that like the Australian Division’s Cavalry Regiment some Italian tanks might end up having to be used. The men had all been fully informed about the Panzer II, III and IVs captured in Flanders. If the rumours were true and that Hitler was going to prop up Mussolini, then going up against the German tanks in a Valiant was likely to be a much better experience than facing them in an A9 or A10.

NB. None of this is OTL.

The A10 tanks of 1st and 6th Battalion RTR, and the A9 tanks of 7th and 8th Hussars had picked their way carefully back over the tracks of Cyrenaica to Bardia. 7th Armoured Division’s RAOC workshops had taken over Italian installations which allowed a fairly efficient processing of vehicles. While the rest of the Division had been in action, the wrecked tanks had been gathered from various points and entirely stripped of anything of value. This added to the supply of spare parts.

The tanks went through what in other situations might be described as triage. The tanks that were literally on their last legs, usually they had been towed back to Bardia, were put to one side. The RAOC Officer in Command marked them to be shipped back to the Delta to the main depots and workshops. They would need a lot of man-hours to get them fixed up, and would drain the stores at Bardia of vital parts.

The second lot of tanks were those with known defects. Each tank was inspected and a report of what was needed to bring it up to full operations was noted. The question was whether or not the defects could be fixed from the existing stores and how long it would take. If it could be done with the resources at hand and in a timely manner, they were put to one side and would be worked on. Those needing more profound work would join the shipment back to the Delta.

All the other tanks, the Division’s ‘runners’, tended to be overdue on their servicing needs and there were jobs beyond the capability of their own crews that needed time in the workshop. These were the first to be worked on. All four Regiments had been together a long time, and were used to mucking in with the fitters and mechanics of the Divisional workshops. The objective was getting as many of the ‘runners’ up to full capability. If possible, General Creagh wanted at least one Regiment’s worth of each type ready for action, just in case.

With word coming through that the Division was to be re-equipped with Valiant Mark I Infantry Tanks, the men of the four regiments started working with the 44th & 48th Bn RTR to become familiar with the new type of tank. For the men of the two Royal Tank Regiment Battalions swapping an A10 for a Valiant was like an upgrade. For much the same speed, they were getting vastly more protection, range and comfort. The same 2-pdr gun meant that it wasn’t a complete upgrade, but so far, the 2-pdr had proven itself a useful tool. The Hussars were more conflicted. The speed difference between the A9 and Valiant wasn’t that vast, and if pushed for honesty, there weren’t that many times that the A9 had been driven at its supposed top speed. The increased armour was certainly a big change. The Italian anti-tank guns were a real threat to the A9, the Valiant would be all but invulnerable. The problem was that the tank was the Infantry Tank Mark III, not a cruiser tank. Somehow it felt that their cavalry heritage was being lost using a tank designed to support the foot-infantry, rather than the dashing efforts of reconnaissance, screening and exploiting.

In the days that followed, as the men worked hard, and had their stories to tell of the victories over the Italians. Generally, there was a very positive mood in 7th Armoured Division about the new tanks they were going to get. There was much to learn about diesel engines and a suspension system that felt like a step backwards over the ‘slow motion’ of the A9 and A10. There was a lot of discussion about the relative merits of one kind of tank against another, and some had feared that like the Australian Division’s Cavalry Regiment some Italian tanks might end up having to be used. The men had all been fully informed about the Panzer II, III and IVs captured in Flanders. If the rumours were true and that Hitler was going to prop up Mussolini, then going up against the German tanks in a Valiant was likely to be a much better experience than facing them in an A9 or A10.

NB. None of this is OTL.