7 October 1939. London, England.

The Under Secretary of State for War, Sir James Grigg, was lunching in his club with Peter Bennett, the Director-General of Tanks and Transport (DGTT) in the Ministry of Supply. Grigg had received a strongly worded letter the day before from General Roger Evans, commander of 1st Armoured Division. He shared the letter with Bennett and they talked through what they could do about it.

Evans had drawn Grigg’s attention to the ‘grave deficiencies’ in the organisation and war establishment of the Division. The plan was to have 1st Armoured Division ready to take to the field on 1 May 1940. With the mobilisation of the Division on 1st September the influx of reservists had meant that the Division was fully taken up with reorganisation and basic training. There was little scope for doing any training at Regimental level, never mind Brigade or Divisional level. This was partly because of the lack of vehicles, but partly also because of an outbreak of foot and mouth disease which limited the availability of training grounds.

Grigg wanted to know from Bennett what the Ministry of Supply was doing before he replied to the letter. Bennett had spoken to Leslie Burgin, the Minister, about the need to increase the production of tanks, and that therefore it needed to pushed up to the highest level of national priority. Bennett encouraged Grigg to do the same with his own Secretary of State for War, Leslie Hoare-Belisha. If the Cabinet could be persuaded of this, then it would make a difference to tank production over the next few months.

The war establishment for 1st Armoured Division that Evans expected was 58 A10s as ‘heavy cruisers’; 159 ‘light cruisers’ which would be a mixture of A9s and A13s; 24 CS cruisers, most of which would be A9s, and 108 light tanks. The Light tanks were meant to be the Mark VII (A17) with the 2-pdr gun, but since these were still to see the light of day, all were in fact the machine-gunned armed Mark VI. In addition to these 349 tanks, the Division expected to have seven Armoured Control Vehicles and 93 scout cars, of which they currently had not a one. With the current shortage of cruisers, the Armoured Division were equipped with more than 200 Mark VIs but really needed the cruisers. When the cruisers came along, the Light Tanks would be passed on to Cavalry Regiments being mechanised. Bennett noted that the order for 120 Mark VII had been allocated to North British Locomotives which meant that it could be mid-1940 before any of these tanks began to be available, far too late for the 1 May deadline.

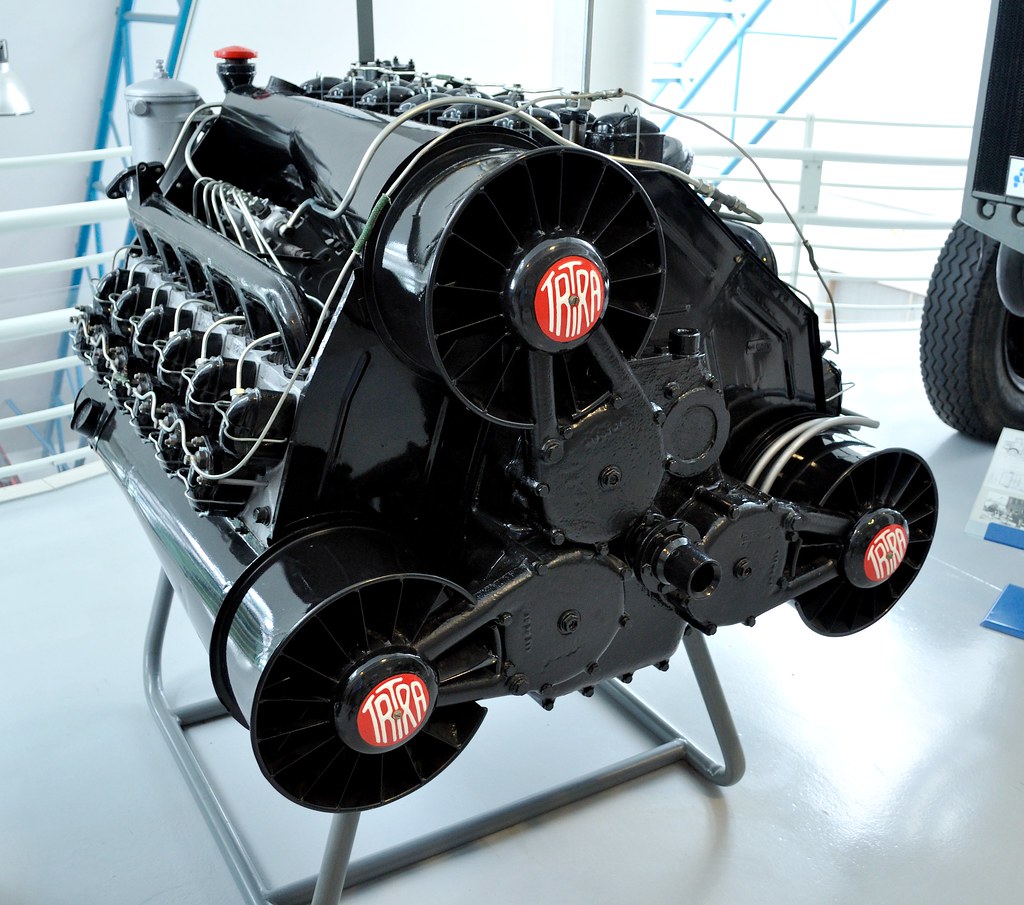

Evans had made the decision that the Heavy Brigade would concentrate on the Vickers tanks: 58 A10s, 84 A9s, as well as the 24 A9CS versions, to ease the maintenance problems since all these tanks had the same engine and suspension. Made up of 2nd, 3rd and 5th Battalions RTR, the Heavy Brigade, with current production numbers, wasn’t expected to fully equipped until January. General Evans remarked that if the 40 A9 and A10s hadn’t been sent to the Mobile Division in Egypt, his Heavy Brigade would be closer to its completion.

The Light Brigade, made up of The Queen’s Bays, 9th Queen’s Royal Lancers and 10th Royal Hussars, would expect to each be equipped with 36 light tanks and 22 light cruisers. As the light tanks weren’t the desired A17 with the two-pounder gun, General Evans suggested that it would be better if they were equipped entirely with gun armed light cruisers. The Light Brigade’s current requirement of 72 cruisers would then rise to 174. Nuffield who was building the A13s, expected delivery of the 65 Mark Is to be completed in October, the Mark II with the thicker armour would start arriving from then on. By the end of January, it was expected that the Light Brigade too would be equipped with all its current requirement of 72 light cruiser tanks. If Evan’s request to have a full Brigade’s worth of A13s, that would take at least until the end of May to be done, providing that no other units received any production A13 Mark IIs.

While a full complement of tanks by the end of January was something to be grateful for, Evans noted that the Support Group was even slower at being formed than the tank regiments. There was no sign of the Royal Horse Artillery Regiment being assigned. He had been told that it might join them in France at some point after 1 May 1940. Likewise, the Light Anti-Aircraft/Anti-tank Regiment existed primarily on paper; of the two Motorised Infantry Battalions, one had been sent to Northern Ireland; and the Royal Engineers Field Squadron was deficient in its technical equipment, especially in regards of bridging equipment. The Royal Signals were 100 men short of their establishment; there was only one of the seven required RASC companies; and the RAOC were far short of what was needed, for example, they only had two of the eighteen breakdown lorries, and these were missing their trailers.

General Evans, however, had noted that ‘it is not the provision of material alone which forms the determining factor in our readiness to take to the field, but the provision of material in time to allow an adequate degree of training to be carried out before we go to war.’ He reminded Grigg that he had less than seven months before 1 May. It wasn’t just that he was deficient of important equipment, but also for the personnel trained to use it, as ‘It is not a matter of a week or two to complete our training on receipt of our equipment; it is a matter of months.’ He went on in his letter to say, ‘If this Division is to be ready to take to the field on 1st May 1940, the greater part of its equipment and armament must be in our hands at the beginning of the year; if it is not, the date of our readiness for war must be correspondingly postponed.’

The idea of a postponement wasn’t acceptable to anyone. If anything, with the situation unfolding in Poland, the need to get the 1st Armoured Division integrated into the BEF was all the more urgent. Thankfully Lord Gort was insisting that he didn’t want any more untrained and ill-equipped units under his command. The current situation of the BEF in France was bad enough without having yet another Division that would be better served getting themselves up to speed at home before being deployed across the Channel. The process of moving the BEF into position was proceeding as planned, but it was the largest scale operation undertaken by the Army since 1919, and therefore there were plenty of problems that Gort didn’t want to add to. John Grigg noted that the chances were that the shortages that Evans had identified in 1st Armoured Division were the result of the cupboard being stripped bare of anything useful by the regular forces making up the BEF.

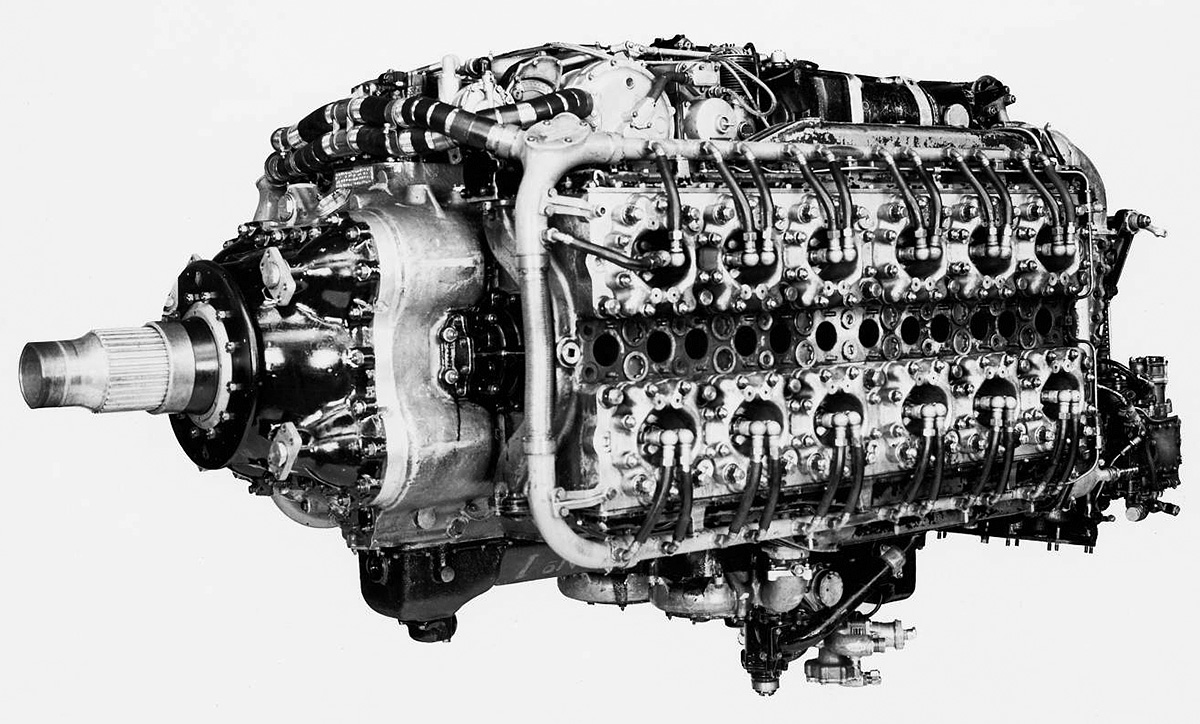

Evans had also noted in his letter that when the tanks were delivered, they often were lacking their gun, which would be delivered separately and then have to be mounted and properly sighted. There was often a gap between the arrival of the tank from the manufacturer and the main armament being available. The bottleneck of producing enough 2-pdrs for both the increasing number of tanks and anti-tank regiments was proving to be a problem. This was made more complicated with the decision to move from the Vickers .303 co-axial machine gun to the BESA 7.92mm gun. There weren’t enough of the new Czech designed guns for training, never mind being available for tank use something that once again was a production problem. It would mean that later versions of the A13 Mark II would be equipped with a different co-axial machine gun. The A10 Mark IA and A13 Mark IIA, whose turrets would be redesigned to take the air cooled machine guns, would complicate logistics if they had to provide 7.92mm ammunition as well as .303 and 0.5 for the Vickers guns. The larger 15mm BESA which was also being introduced, was proving to be full of production bugs, delaying its availability. Evans did admit that if the Light Tanks were armed with this cannon in the Light Brigade, it would go somewhat towards improving their capability until the A13 cruisers were available.

Grigg noted that even if the production numbers of tanks was going to go up by giving a higher priority, the probability remained that the delivery of guns for the tanks wasn’t going to keep up. That was something that Campbell Clarke at Woolwich would have to deal with. It had been suggested that the Mark VII (A17) might have been armed with the Vickers 2-pdr pompom that was used on the A11. If that was possible, then it would save 120 QF 2-pdrs for the cruiser tanks. If Clarke could be convinced that the Light Tanks would be better off with that gun rather than a dedicated anti-tank gun, then it would help. Neither Grigg nor Bennett were convinced Clarke would agree.

Both men knew that there were so many new types of weapon being acquired that there was always going to be a backlog in fielding the necessary numbers. Bennett had visited the Royal Ordnance Factory in Nottingham where 2-pdrs were being produced, along with both 3.7-inch and Bofors 40mm AA guns. They were also in the running to build the new 5.5-inch medium gun for the Royal Artillery. The workforce in this factory, like all the others, was increasing. Delays in training new employees as well as delays in sourcing machine tools meant that it would take time before increased production was possible.

General Evans letter to Grigg had one last comment. He had recently been at Farnborough and seen the Valiant Mark I*, the cruiser version of the Valiant with the petrol engine and thinner armour, go through its paces. Evans had noted that it fitted the bill for a heavy cruiser much better than the A10. In fact, despite its weight and speed, he could see it being much more useful than all the current cruiser tanks. He had also seen the Valiant Mark I, which despite being named an Infantry Tank, was, to his mind, also a far better tank than the current crop of cruisers. He hoped that both models would be available as soon as possible, and if pressed, he believed the Mark I would probably be the better bet in the long run.

Over a brandy, Bennett and Grigg noted that they had both seen the proposal for Vickers Valiant Mark II whose turret had been designed with the new 6-pdr gun in mind. If they could persuade their respective Ministers to ask that a new production line for the new gun could be opened up as soon as possible, allowing for the early entry into service for that weapon, it would be a wise move. Bennett noted that the Vickers-Armstrong company had made bids for producing the 57mm weapon, as they had produced that bore of gun previously for the Royal Navy. Currently Woolwich hadn’t finalised the design for the gun carriage, and there were problems with the number of lathes available for the preferred L/50 calibre. Vickers were keen on going with a L/43 barrel for the tank gun, for which they had the necessary tooling, leaving the anti-tank gun for the Royal Artillery regiments to follow when the carriage was fully worked out. The two men agreed to bring that proposal before their respective Ministers. Grigg would bring the concerns of General Evans to the Secretary of State for War, but just about every commander in all three services were writing letters bemoaning the lack of preparedness for the conflict in which the nation was now embroiled.