Here's an overview of the tanks outlined and/or planned for Manticore v4.3.

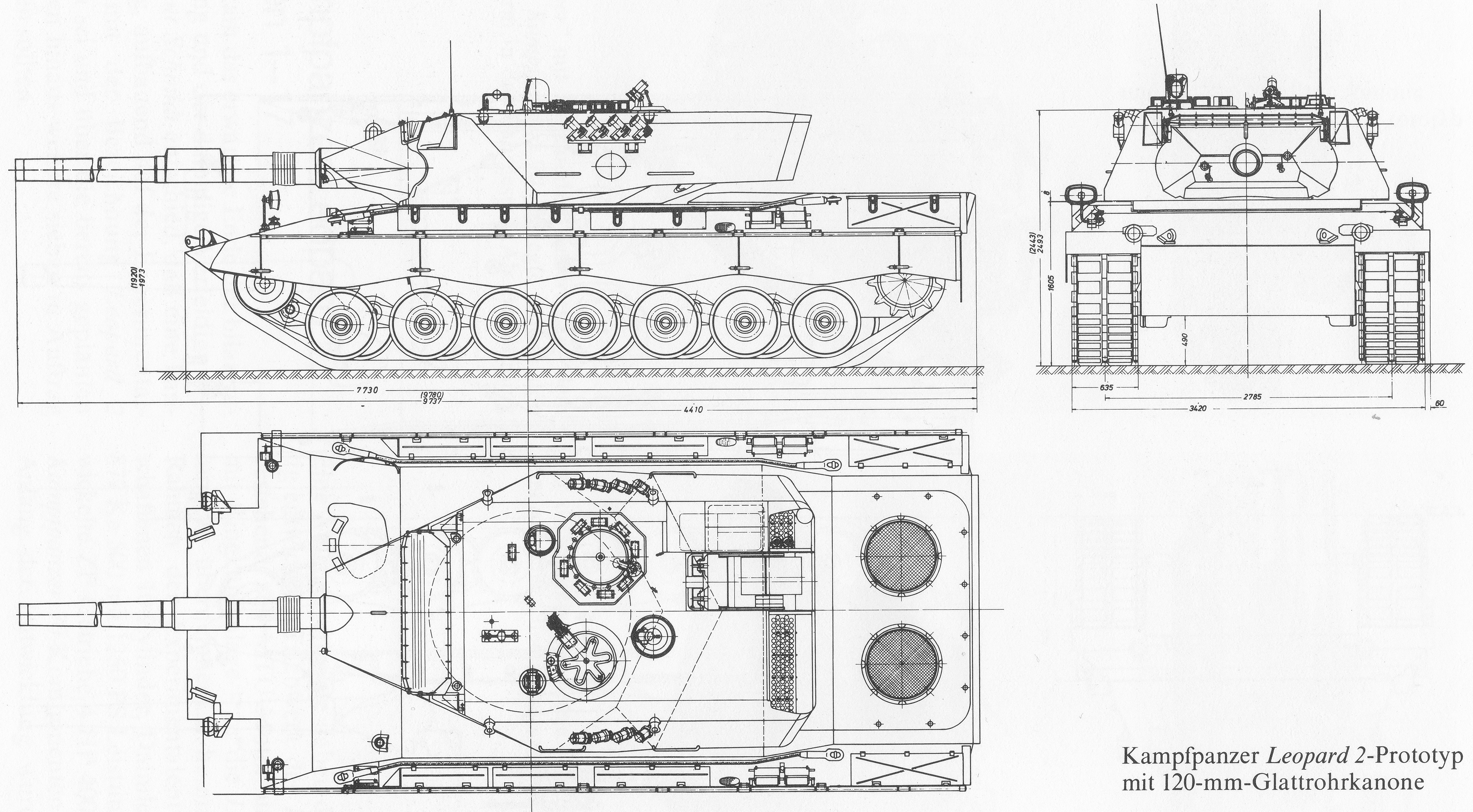

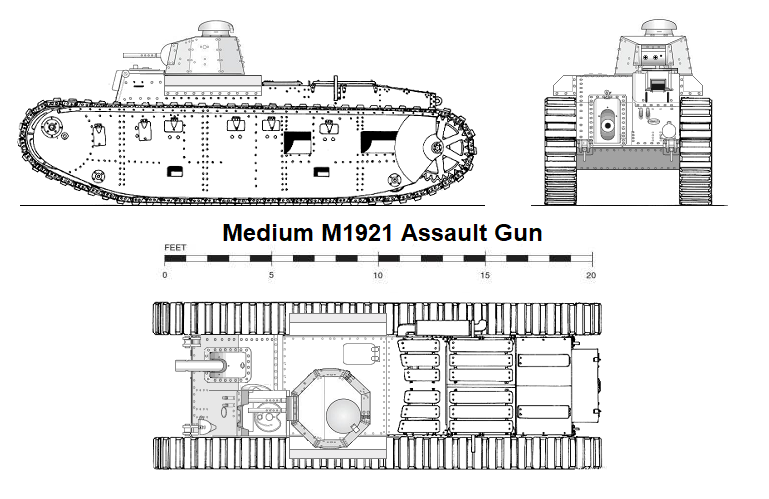

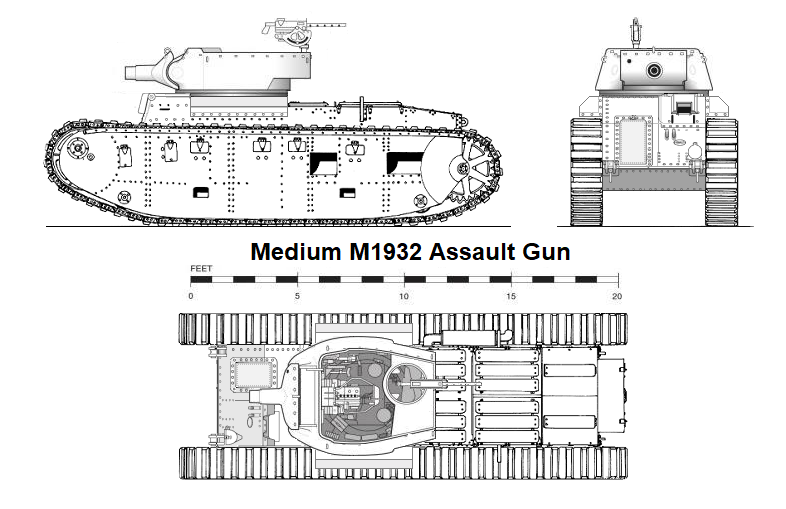

Medium M1921: These began as assault guns based on the US Medium M1921 tank with a hull-mounted 3"/28 field gun. In the 1930s, the vehicles were converted to tanks with 3"/18 howitzers in turrets. Claymore did these drawings of the initial assault gun with the Renault F1 turret. I just noticed that the gun mount in the hull comes from the Char B1, which used a fixed-azimuth mount and thus aimed the gun by turning the vehicle; my intention with this assault gun would be to have a flexible mount and a separate driver and gunner. The gun barrel would also be somewhat longer, I suspect extending out to roughly the front of the track. The turret on the tank variant would probably be somewhat smaller than the drawing and would have a roof.

Vickers Medium Mark D: This is the tank from the late 1920s. It is derived from the Vickers Medium Mark II but has a rear drive with a more powerful engine and a larger turret. One example was sold to the Irish Free State with some kind of 6-pdr gun, probably related to the Hotchkiss gun used on British WWI heavy tanks. This piece has a single recoil cylinder above the barrel; it is exposed in front of the Mark D's turret front but was concealed by armor on the Mark IV and later heavy tanks. The picture below is from the

Tank Encyclopedia page and shows an MG position on the hull side. There is also one in the turret rear. My thinking is that removing all of these extraneous (to Manticore) MGs would allow the turret, mantlet, and turret ring to be enlarged sufficiently to fit a 3"/28 field gun.

Vickers Medium Mark III: This would be the primary tank in production through the first half of the 1930s. My intention is to take the original vehicle and eliminate the forward sub-turrets in favor of an actual driver's position and a hull-mounted MG, and then increase the size of the turret to fit a 3"/28 field gun. This concept has stayed relatively constant for quite a while, and I drew the image below in April 2020 with components (turret, MG mount, driver's hatches) from a Neubaufahrzeug drawing.

Landsverk Lago medium tank: In the previous iteration, an 18-ton variant of the earlier Lago design was produced for a few years as a light-role tank with a Czech 47 mm AT gun. Here, a vehicle broadly equivalent to the Stridsvagn m/42 is built during the 1936 and 1937 production years. The vehicle will weigh roughly 22 tons, with a 3"/28 field gun and armor up to 2 inches, and will run on 12 road wheels (6 per side) on torsion bar suspension. This is a considerable advancement of the OTL schedule, where the m/42 wasn't delivered until April 1943, but it is driven by significantly more rapid development after the Landsverk L-60 is selected as the light tank to replace the Vickers Light Mark III in the mid 1930s. The switch to front-drive sets up the arrangement (rear engine, front drive, 3-man turret) of the remaining WWII-era Manticoran tanks, which is shared with the Americans and Germans. The image from Wikipedia is sufficiently representative of the Manticoran vehicle.

Medium 25-ton medium tank: Here is where Manticoran tank engineering really becomes independent from foreign engineering influence. In 1938, we move more aggressively to a concept of shared vehicle platforms, with tanks, artillery, APCs, command vehicles, etc.. sharing automotive and hull components. The medium tank is the heaviest tank in production, only because a heavy tank similar to the KV is rejected due to poor mobility and reliability. The tank has a 3"/40 gun similar to the 76.2 mm F-34 on the T-34, up to 2 inches of armor, a 5-man crew, and a 325 hp engine. It is broadly comparable to an early-war T-34 or a later Pz IV. The vehicle and associated vehicles will be built during the production years 1938, 1939, and 1940. I made the image below from a stretched Chaffee hull, a Pz IIIL turret, and a 75 mm Pak 97/38 with the muzzle brake cut off. I anticipate that the gun to be used will be the Soviet 76.2 mm divisional gun M1902/30 (the long-barrel conversion), which is available from stocks captured during the intervention in the Russian Civil War and pieces purchased from Schneider (who provided the design to the Putilov works in St. Petersburg) to equip the intervention force. Additional new pieces may be procured as necessary to arm additional tanks.

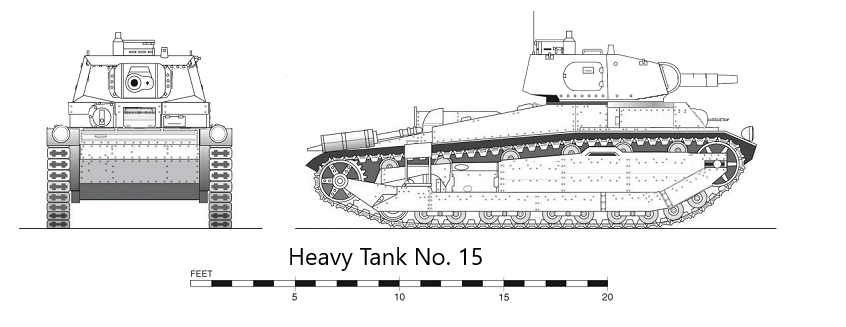

Medium 30-ton medium tank: This vehicle will be in production for the 1941 and 1942 production years. It is a direct replacement for the Medium 25-ton medium tank and was quickly brought into production in response to Soviet heavy tanks encountered in the Winter War. The tank has a longer 3"/50 gun, up to 2.5 inches of armor, a 5-man crew, and a 450 hp engine. The image below is what I made in August 2020, from a T-34M hull and turret and a Panther gun. The gun was shortened from the original and the T-34M's turret was moved slightly rearward to reflect the rear-engine, front-drive layout.

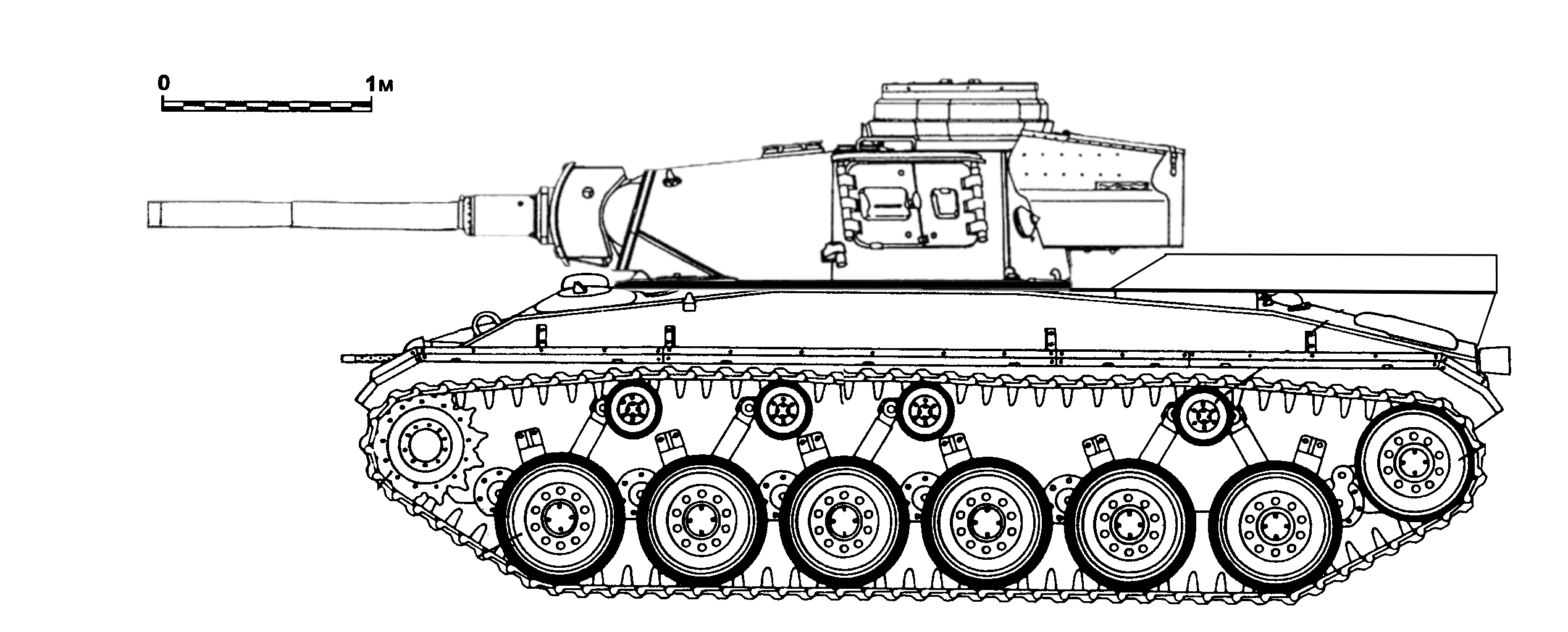

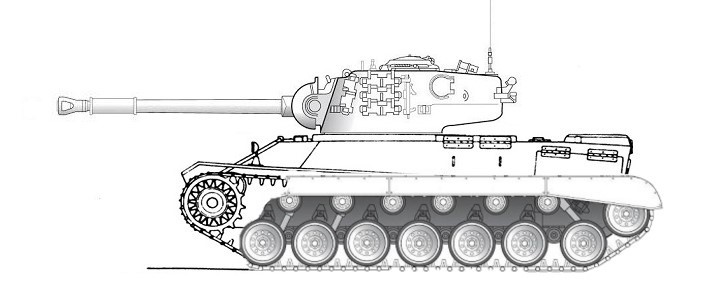

Medium 40-ton medium tank: This is the next iteration of the medium tank program, fielded in response to heavier tanks like the Soviet IS and the German Tiger I. With the weight increase, the gun is upgraded to a US 90 mm M3, hull and turret armor increases to 3 inches, and power increases to 600 hp. I made the image below in August 2020 from a 44M Tas hull, an M26 turret, and an stretched M26 suspension. My intention is that turret armor would be closer to the T25 (roughly 3 inches) rather than the T26 (roughly 4 inches). It may be possible to upgrade these vehicles to later US 90 mm guns like the more powerful 90 mm Gun T54, which was installed in Pershing turrets as part of testing.

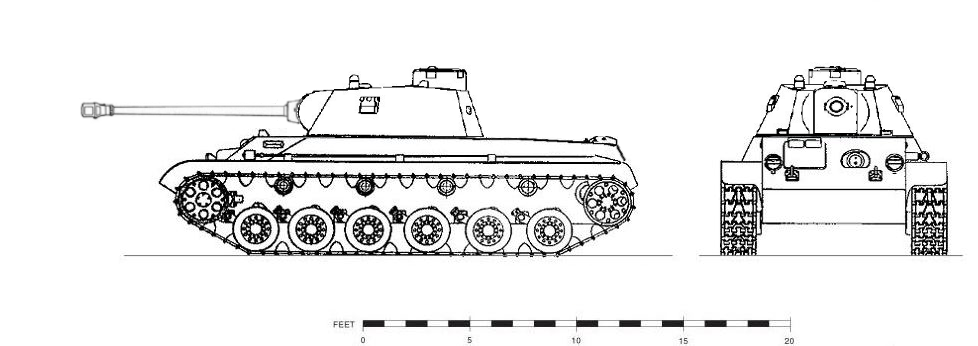

Medium 50-ton medium tank: This is the vehicle that will be built beginning in the 1945 production year. Production will continue as necessary in the post-war period. The main purpose of the vehicle is to introduce a larger gun matching the 88mm L/71 on the Tiger II. My intention is a 90 mm L/60 with a 90 x 600 mm (R/150mm+) similar to the 90 mm Gun T54 mounted on the M26E1 medium tank, which would be somewhat more powerful than the QF 20-pdr. This could be exchanged for the 105 mm L7 at a later date, which would provide a gun only slightly more powerful but lighter and with better AP and HEAT ammunition. I made the below drawing in 2018, indicating a hull design somewhat similar to the Panther, with a rear-engine, rear-drive, and a 750 hp+ engine. The turret is very loosely inspired by the Panzerfront E79. Considering the increase in size, I suspect a vehicle like this would be somewhat lightly armored compared to a Centurion or a Patton due to the presence of large sponsons. An alternate option for the time and weight range would be the T32 heavy tank, which was a stretched Pershing with the 90 mm Gun T15 seen on the Super Pershing (T26E4) and significantly heavier armor than a normal Pershing.

Medium Tank for the 1960s: This decade has become somewhat of a blindspot for me, mostly because I have never gotten to this point in my TL so I have never had to answer these questions. Compared to the Centurion and M48 Patton, the Medium 50-ton tank remains competitive as long as it gets the 105 mm L7 or a comparable gun. However, the British went for an increase in firepower with the Chieftain's 120 mm L11A5. While not as large as the 120 mm Gun M58 on the M103 and Conqueror, it did represent a fairly significant increase in capability over the 105 mm L7. My primary options here are going to be in the realm of the 105 mm Gun T140 and the 105 mm Gun T210, though I think the 800 cubic inch case on the T210 may require two loaders (the M58 had a 1,021 cu in case). The 120 mm M256 has a 670 cu in case and requires a single loader. I think the optimal solution here might be something along the lines of a 105 mm version of the 90 mm Gun T208, which is an early smoothbore, with a ~500 cu in case and chamber pressure around 54,000 psi. These early smoothbore guns were tested as part of the T95 project in the late 1950s and could be in service around 1960 with concerted development, like the Soviet 115 mm U-5TS in the T-62. Engineering at this point is leaning towards castings as the way to maximize both armor and interior volume compared to welded turrets and hulls, so the result may look more like the Patton than the Panther. The below

image from Wikimedia is of the T54E2, essentially an M48 hull and a larger turret with a T140 gun, which appears in World of Tanks as the M54 Renegade, though the real turret was not nearly that heavily armored.

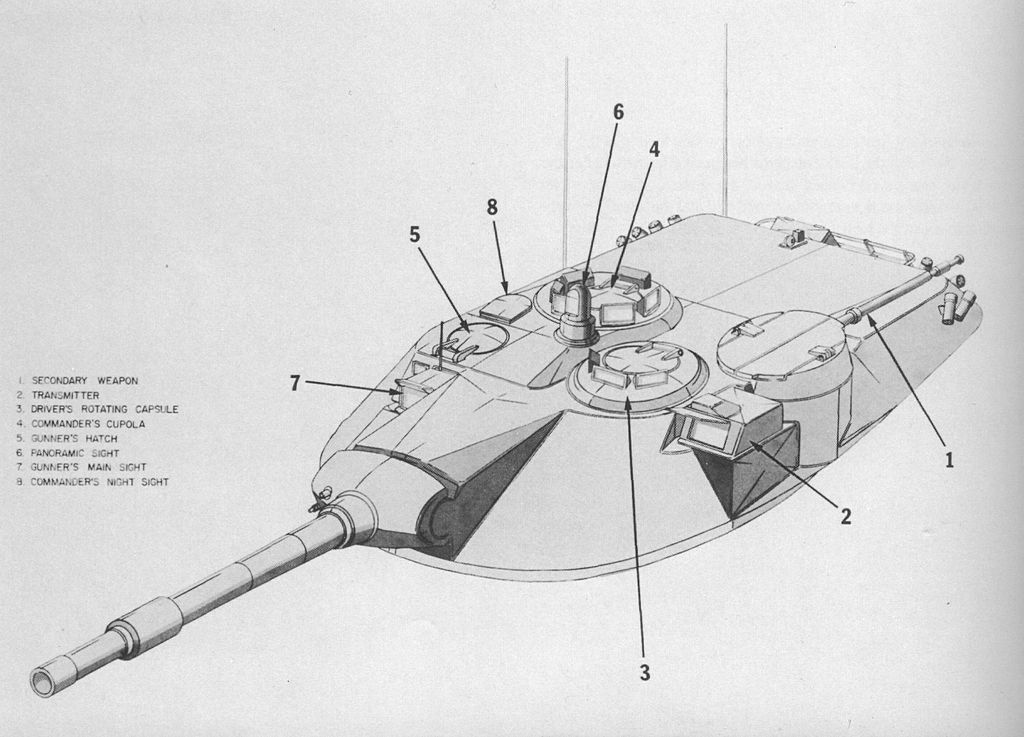

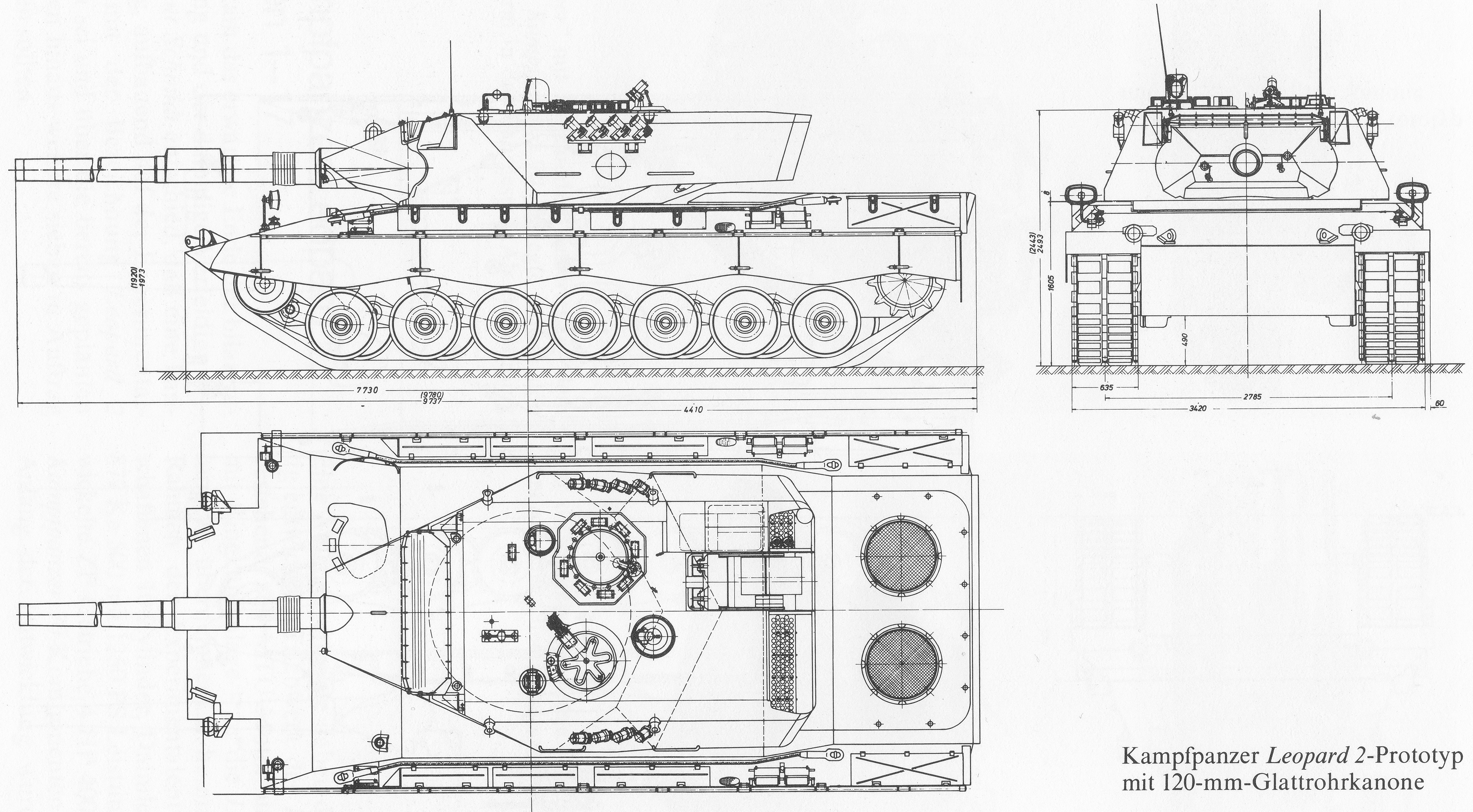

Medium Tank for the 1970s: By the mid to late 1960s, we get a new and fairly magical feature in the form of 1,500 hp diesel engines like the AVCR-1790 and the MTU 873 with extra turbos, digital controls, improved cooling, and variable compression ratios. Weight is no longer limited by mobility and therefore PWR but by logistical concerns like bridging. We also get the introduction of composite armor, which generally provides protection equivalent to a similar depth of RHA at a significantly lighter weight. Ultimately the problem is that the size of these more powerful engines and larger guns like the 120 mm Delta gun will force the mass budget to be spent on increasing the volume of the vehicle rather than the armor. If we stay within the 50-ton weight limit, the resulting vehicle would look like the Leopard 2K. One of the problems with composite armor at this point is that packages like Burlington were not really ready until about 1980, so the most we might be looking at is rubber mats between layers of spaced armor. An alternate turret form for this might look more like the MBT-70 with very large curved forward plates and a similarly large mantlet.

Main Battle Tank for the 1980s: By this point, we absolutely need a turret design that can handle composite armor blocks. The M1's symmetric shape is clearly better compared to the Leopard's placement of the gunner's optics in the turret front, but the Leopard's flat turret front would probably be more amenable to armor upgrades. Gun and engine choices remain the same while weight will probably rise to 65 tons to use the capabilities provided by MLC70 equipment. My main intention with the tank in the 1970s is to introduce some of the equipment that sets 3rd generation MBTs apart from the 2nd generation by up to a decade earlier than the main NATO countries. Once we define a 3rd generation MBT in the 1980s, that design will basically be locked in until a tank with an uncrewed turret like the T-14 Armata becomes a possibility in the 2010s.