You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What If - Finland had been prepared for the Winter War?

- Thread starter CanKiwi

- Start date

Well, the Ilmavoimat did get some Hurricanes from the UK in reality. That won't change.

But here's a preview......

Royal Air Force contributions

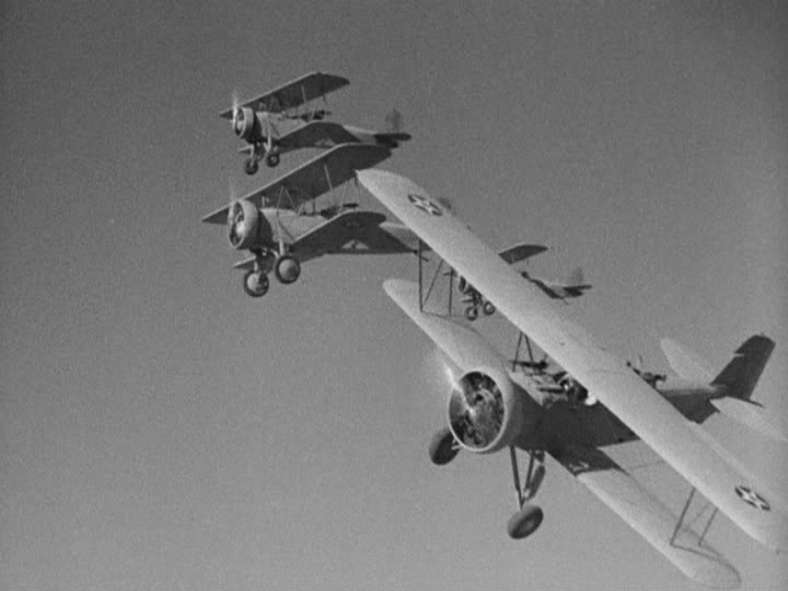

In addition to selling (rather than giving these to Finland as has often been thought) a limited number of aircraft (primarily Blenheims, Hurricanes, Blackburn Roc’s and Hawker Henley’s) to Finland, the Royal Air Force allowed a small number of volunteers from the RAF to assist Finland in the Winter War. Volunteer Pilot and Ground Personnel for a single fighter squadron were formed under the leadership of Squadron Leader James Bigglesworth, a noted RAF pilot with extensive combat and leadership experience dating back to WW1 (note that the biographer of Bigglesworth, WE Johns, falsely accounted for this period in Biggles life in “Biggles in the Baltic” as the British Government did not desire to broadcast the fact that British forces had actually fought against the USSR at the time the book was published - at which time the USSR was an ally against Nazi Germany). Along with the personnel for this squadron, twenty Hawker Hurricanes were transferred together with the RAF volunteers. These were painted in Finnish colours and flown to Finland via Sweden in late-December 1939, with the squadron entering combat in January 1940.

Under the leadership of Squadron Leader Bigglesworth (“Biggles”), the RAF pilots quickly adapted to flying in the extreme conditions of the Finnish winter, as well as to the “Finger Four” formation and the combat tactics used by the Ilmavoimat. The combination of a tightly knit and highly skilled group of RAF pilots, many of whom, such as Biggles himself, already possessed considerable combat experience, together with the adequate performance of the Hurricanes as a fighter led to some spectacular successes against the Soviet Air Force as well as to some incongruous notes. Such as Hurricanes and (Spanish) Me109’s fighting side by side against the Soviet Air Force even as the aircraft fought each other over France. The RAF pilots lost very few of their number, 3 pilots from 20, with 2 of these lost to accidents in the extreme winter weather and only 1 shot down. In return, the 20 RAF pilots accounted for some 120 confirmed kills and a further 50 odd probables. The RAF volunteers later fought in northern Norway in support of Finnish units intervening in the Norwegian campaign, and later returned to fight in the UK during the Battle of Britain as the German blitz commenced in full force.......

But here's a preview......

Royal Air Force contributions

In addition to selling (rather than giving these to Finland as has often been thought) a limited number of aircraft (primarily Blenheims, Hurricanes, Blackburn Roc’s and Hawker Henley’s) to Finland, the Royal Air Force allowed a small number of volunteers from the RAF to assist Finland in the Winter War. Volunteer Pilot and Ground Personnel for a single fighter squadron were formed under the leadership of Squadron Leader James Bigglesworth, a noted RAF pilot with extensive combat and leadership experience dating back to WW1 (note that the biographer of Bigglesworth, WE Johns, falsely accounted for this period in Biggles life in “Biggles in the Baltic” as the British Government did not desire to broadcast the fact that British forces had actually fought against the USSR at the time the book was published - at which time the USSR was an ally against Nazi Germany). Along with the personnel for this squadron, twenty Hawker Hurricanes were transferred together with the RAF volunteers. These were painted in Finnish colours and flown to Finland via Sweden in late-December 1939, with the squadron entering combat in January 1940.

Under the leadership of Squadron Leader Bigglesworth (“Biggles”), the RAF pilots quickly adapted to flying in the extreme conditions of the Finnish winter, as well as to the “Finger Four” formation and the combat tactics used by the Ilmavoimat. The combination of a tightly knit and highly skilled group of RAF pilots, many of whom, such as Biggles himself, already possessed considerable combat experience, together with the adequate performance of the Hurricanes as a fighter led to some spectacular successes against the Soviet Air Force as well as to some incongruous notes. Such as Hurricanes and (Spanish) Me109’s fighting side by side against the Soviet Air Force even as the aircraft fought each other over France. The RAF pilots lost very few of their number, 3 pilots from 20, with 2 of these lost to accidents in the extreme winter weather and only 1 shot down. In return, the 20 RAF pilots accounted for some 120 confirmed kills and a further 50 odd probables. The RAF volunteers later fought in northern Norway in support of Finnish units intervening in the Norwegian campaign, and later returned to fight in the UK during the Battle of Britain as the German blitz commenced in full force.......

What's in the pipeline?

In the "immediate" Pipeline - more on Valtion Lentokonetehdas (State Aircraft Factory) and the ongoing constructions program for the Ilmavoimat thru the 1930s up to the Munich Crisis - with a bit of an interesting little twist.

Also working on the Coastal Artillery but that's taking up a lot of research time - and I had most of the Air Force stuff drafted so I'm finishing that off first while I plug away at the Coastal Artillery. Which should come next.

Then it's a sideways jump to Foreign Affairs thru the 1920's and thru to about 1935.

More great updates! What's in the pipeline?

In the "immediate" Pipeline - more on Valtion Lentokonetehdas (State Aircraft Factory) and the ongoing constructions program for the Ilmavoimat thru the 1930s up to the Munich Crisis - with a bit of an interesting little twist.

Also working on the Coastal Artillery but that's taking up a lot of research time - and I had most of the Air Force stuff drafted so I'm finishing that off first while I plug away at the Coastal Artillery. Which should come next.

Then it's a sideways jump to Foreign Affairs thru the 1920's and thru to about 1935.

And now, back to Valtion Lentokonetehdas...

And now, back to Valtion Lentokonetehdas

Before we run through a history of aircraft construction by Valtion Lentokonetehdas, we’ll take a more indepth look at the new factory and at one of the key engineers – Arvo Ylinen.

Arvo Johannes Ylinen (b. Yläne, Southwest Finland on 5 March 1902 – and died 27 July 1975) was an aeronautical engineer and late a Professor of Aeronautical Engineering. His father was Juho Ylijaakkola and his mother was Sofia Emerentia Uusitalo. Arvo Ylinen graduating from high school in Turku came in 1923, attended University and graduated in 1930 with a Master of Science ”with Distinction” in Engineering, which was then very rare. In the same year he completed the CDI's military technical department graduate course. He studied aviation engineering at the Charlottenburg Technical School of the Berlin University of Technology over 1930-31 and later completed a doctoral thesus, which he defended at TKK in 1938. His dissertation was the first aircraft technology thesis completed in Finland.

He joined IVL at Suomenlinna, first working as a Design Engineer from 1932 to 1933. He was soon promoted to Office and Drawing Manager, a position he held from 1933 to 1934. In 1934 he was married to Lea Maria Hietarinta, a Medical Doctor. He held the position of Construction Manager from 1934 to 1937 and Technical Director from 1937-1940. He became the first TKK Professor of Aeronautical Engineering in 1940, a position he held until 1956. At the same time, he continued to serve as an Advisory Engineer to Valtion Lentokonetehdas from 1940 to 1949. From 1956 to 1967 he was Professor Engineering whilst also working as a Laboratory Director for VTT from 1952 to 1956. He chaired the National Defence Scientific Advisory Committee for 4 years from 1 October 1961. He received numerous awards and wrote and published many books and articles and held the rank of Lieutenant Colonel in the Army. Arvo Ylinen died on 27 July 1975.

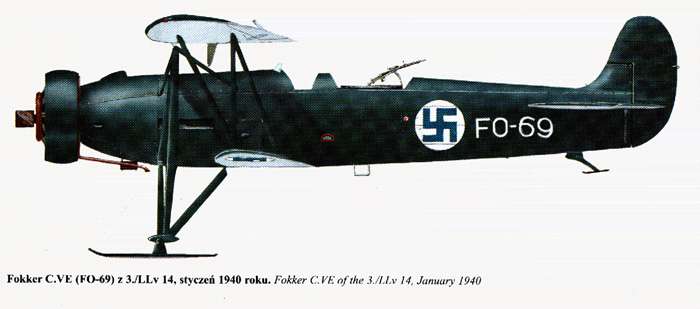

Arvo Ylinen was instrumental in the major achievements of ”success years” of Valtion Lentokonetehdas, holding the key positions of Construction Manager from 1934 to 1937 and Technical Director from 1937-1940, the period in which VL expanded its capacity dramatically and manufactured the aircraft that would be critical to Finland’s survival in the Winter War. Ylinen, the Manager of Valtion Lentokonetehdas (xxx), Rudolph Walden as Chairmain of VL’s Board of Directors and Major-General Somersalo were between them the key figures responsible for increasing aircraft production, directing the selection and mix of aircraft and making sometimes risky and at times also radical decisions which in turn enabled the Ilmavoimat to outclass and outfight their opponents at every stage of the Winter War and through WW2. Even towards the end of WW2, aircraft such as the Ilmavoimat’s Fokker G1 and the Heinkel He112 Fighters were, thanks to continual upgrades, still effective fighters capable of more than holding their own. In the Winter War, they proved to be devastatingly effective, as we will see.

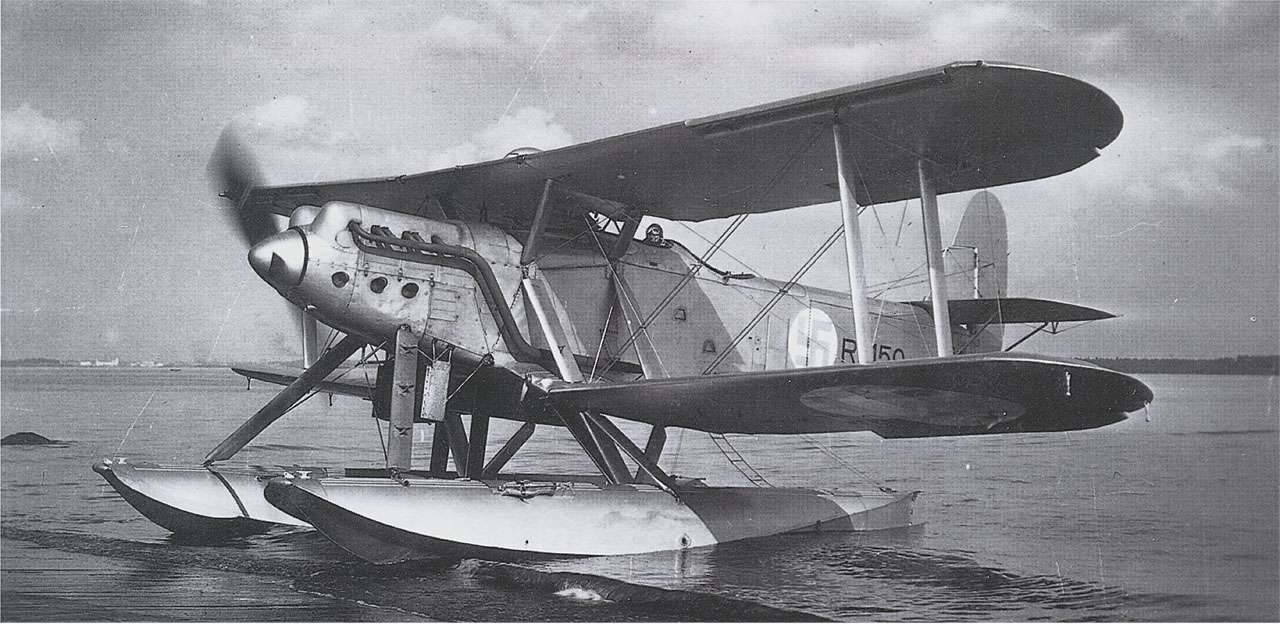

Returning now to the Valtion Lentokonetehdas factories, the works at Suomenlinna and Santahamina continued to be utilised through the first half of the 1930’s, with some limited construction of indigenous designs, construction of foreign aircraft under licenses and the assembly of aircraft purchased from foreign suppliers. The early years of IVL and VL had seen some mistakes – not the least of which had been the disastrous purchase of the Koolhoven FK.31 from the Netherlands virtually ”on spec”. At the same time, relations between the Commander of the Ilmavoimat, Major Somersalo and the General Staff had not improved to any great extent. As you may recall from an earlier Post, in 1924 the British Maj. Gen. Walter Kirke and a small team of British military advisors had carried out a Defence Review and made a number of recommendations on Finland’s defences, including recommendations that the Ilmavoimat concentrate on a float-plane based development plan. At the time this plan had been strongly opposed by the Commander of the Ilmavoimat, Major Somersalo. However, Somersalo’s views had been overruled by the General Staff, who were more inclined to take account of the recommendations of the so-called British ”experts” rather than those of a relatively junior Finnish Officer. Somersalo however had soldiered on despite the many obstacles in his path, doing his best to work around the limitations imposed by the Kirke Review, the views of the General Staff and the relative independance of I.V.L, which also caused many problems.

Relations between the General Staff and the Ilmavoimat Commander in 1930 were, as we have mentioned, not of the best. Major Somersalo did his best to work with what he had, but the funds allocated to the Ilmavoimat were limited, within the military hierarchy he was a fairly junior office and while serving as Commander of the Air Force, he had not been promoted – the Maavoimat was by far the larger and more influential of the services, commanding the lions share of the limited military budget through the 1920’s (albiet with increased naval spending in the latter years of the decade) and many of the decisions made were out of his hands and not subject to his control or influence. And the shift in control of Valtion Lentokonetehdas from the Ilmavoimat to the Ministry of Defence in 1928 had been just one more issue he had to face. Somersalo however persisted in the face of adversity, continuing to emphasize the development of a mix of capabilities, demanding the development of combat flying skills from his squadrons, continually emphasising the need for close support teamwork with the Maavoimat (Army) and Merivoimat (Navy) and doing his best to workaround the limitations imposed by the recommendations of the Kirke Review and the views of many in the Maavoimat, who at best considered the Ilmavoimat something of an irrelevance – useful perhaps for reconnaisance or artillery spotting but not much else. There were of course exceptions – the theorists in the Maavoimat making up most of these – but they tended to be the younger and more junior officers.

And then, in 1930 the General Staff set up a Restructuring Committee to look at the Ilmavoimat and aircraft purchasing and construction. The Committee completed their report in 1931 and stated among other conclusions that the views of the British Advisors from 1924 were obsolete. As a result the General Staff decided to improve their aviation warfare skills knowledge and appointed their own air defense officer. Lieutenant-Colonel Aarne Snellman was appointed to the post and almost immediately harshly criticized the constraints and operating limitations that had been imposed on the Ilmavoimat and expressed support for the views of the Commander of the Ilmavoimat, Major Somersalo. It was at this point, in March 1931 that Mannerheim was appointed to chair the Defence Council and also commissioned as overall Comander-in-Chief of the Armed Forces with Rudolph Walden appointed Minister of Defence in the All-Party Consensus of 1931. Mannerheim immediately initiated the 1931 Military Review, which was completed some six months later – and it was a six month period of heated and sometimes vitriolic debate within the Finnish Armed Forces.

Aarne Snellman: (2. December 1894 - 28 April 1940 Helsinki): Snellman's father, Wilhelm Snellman was a district physician, his mother was Alexandra Sittkoff. Born on 1894, he matriculated from the Savonlinna Real Lyceum in 1912 and joined the Savo Students' Association. He continued his studies over the years 1912-1914 at the University of Helsinki Faculty of Philosophy and Economics and completed a first degree in Agriculture and Forest Management. He volunteered for the Finnish Jaegers and was awarded the German Iron Cross (Gruppenführer, JP27, awarded 1/26/1917). During the Finnish Civil War, Jaeger-Captain Snellman commanded Artillery Brigade 3. In 1920 he attended the French Military Pilots' School (Ecole d'Aviation Istres) and in 1921 he completed Finnish Pilot training (it was this early aviation background that led to Snellman being appointed General Staff Air Defense Officer).

He completed the Suojeluskuntas Officers course in 1926 and War College training over 1926-27. In 1927 he married Hildegund von Numersin. From 1934 to 1938 he served as Military Attache in Germany, from 1938-1939 he was the Commanding Officer, 3rd Field Artillery Regiment and over 1939 to early 1940 he was the Commanding Officer, Artillery, IV Corps. He was appointed Acting General Officer Commanding 12th Division following the death of the Division Commander in action, and after a replacement was found he took over as General Officer Commanding 17th Division. Colonel Aarne Snellman, commander of 17th Division, was seriously wounded when Soviet aircraft bombed his command post at Vaaseni on 13 April 1940. Promoted to Major-General on 26 April 1940, he died of wounds two days later.

OTL Note: real date of death was 26 April 1942 – events otherwise occurred as described. Some command periods adjusted, in reality he commanded these Divisions during the Continuation War.

For the Ilmavoimat and for Valtion Lentokonetehdas, the consequences of the 1931 Military Review were far-reaching, if sometimes slow to take effecxt. The views of the Restructuring Committee and Snellman’s report of 1931 as well as contributions from Somersalo and other Ilmavoimat officers were rolled into the 1931 Military Review, and having kept abreast of military affairs, Mannerheim and Walden were no strangers to the issues. Among Mannerheim’s first steps were the promotion of Somersalo to Lieutenant Colonel on 10-October-1931 (and to full Colonel on 8 September 1932 and then to Major-General in 1933 – a rapid rise indeed), the public expression of full support for Somersalo and a demand for immediate plans to be completed for the expansion both in capabilities and size for the Ilmavoimat and immediate financial budgetary arrangements allowing for the purchase of additional aircraft in 1931 and 1932. The other step (not quite so immediately) Mannerheim took was to change the management of Valtion Lentokonetehdas – on 1 January 1932, Engineer Erkki Mäkinen was appointed as Managing Director from among 24 applicants and Rudolph Walden became Chairman of the Board of Directors, giving him immediate oversight. The move of the Valtion Lentokonetehdas factory to Tampere was also approved at this time, although in this case it was Walden’s views on the location of the factory that carried the day. This incidentally, tended to be the general tenor of decisions taken by the Defense Triumvirate – Mannerheim tended to win the straight-out military decisions, Walden the industrial decisions and Ryti the financial. Where politics intruded, the views and influence of Vaino Tanner inevitably came into play, resulting at times in some interesting (but almost always practical) compromises.

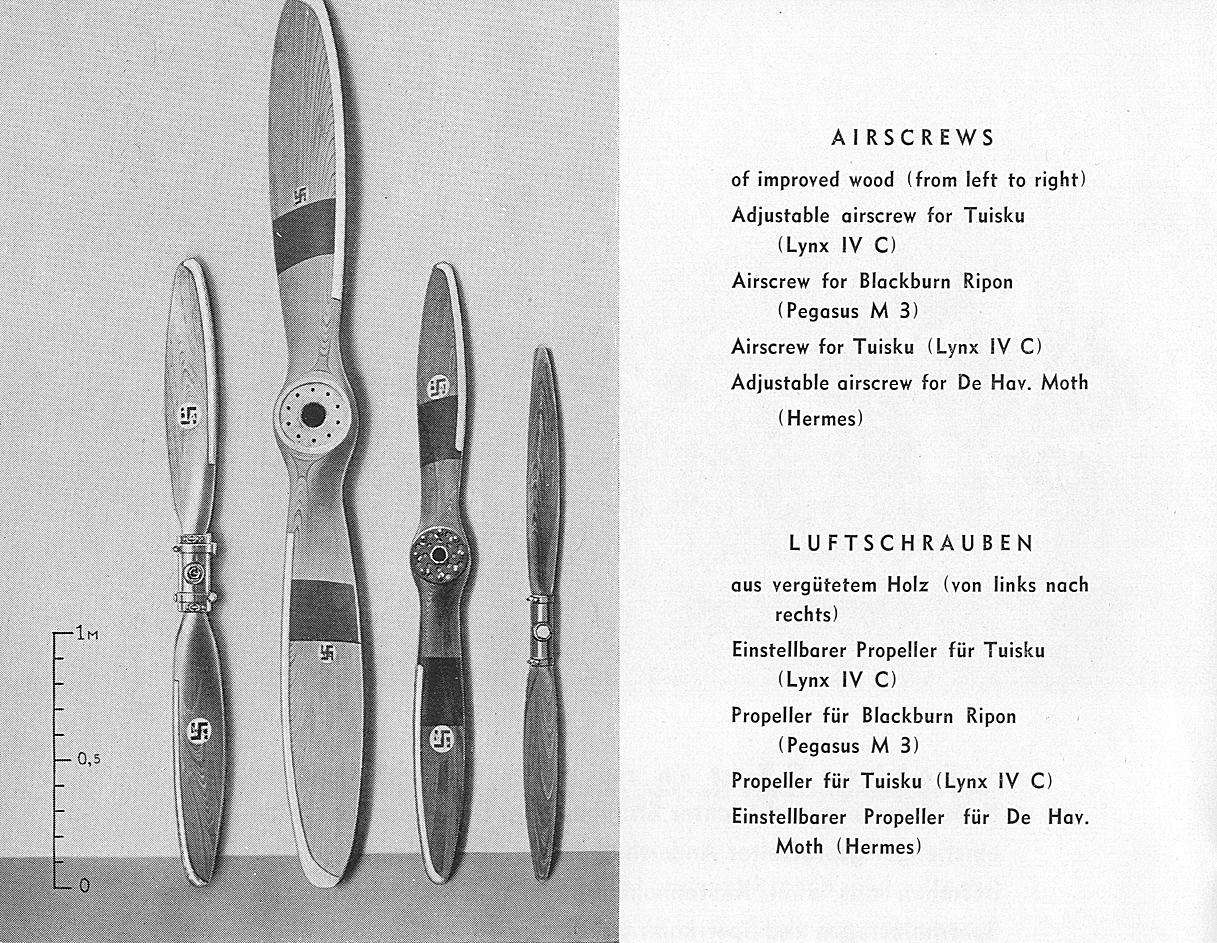

We have already looked at the early attempts of IVL to design and build indigenous aircraft with the Berger designs for the C.24 and C.25, as well as the Kurki (“Järvinen's crate"). As a result of these failures, aircraft purchases had concentrated on either the purchase of built-up aircraft or the construction of imported designs built under license. The 1931 Military Review envisaged this mix continuing. It was considered too risky to rely entirely on aircraft purchased from foreign suppliers – in the event of war access to these would in all likeliehood be cut off. A domestic manufacturing capacity was needed, and it needed to be adequate to cope with the demands of the military in a war-time scenario. Stategically, attention was also paid to building up the ability to manufacture key components within Finland – hence the emphasis on the engine manufacturing capacity which resulted in the setting up first of the State Aircraft Factory (manufactiring Bristol Mercury and Rolls Royce Merlin engines under license) and then of the Tampella-Hispano-Suiza Factory (maunfacturing Hispano-Suiza aircraft engines). Likewise, there was a parallel emphasis on building up gun-manufacturing capacity – one component of which was the Hispano-Suiza 20mm cannon manufacturing plant.

Earlier mistakes, such as the purchase of the Koolhoven FK.31 from the Netherlands, the failure of the C.24, C.25 and Kurki projects were reviewed and initiatives currently underway which were experiencing problems such as the manufacturing of the Ripons were also looked into. A further issue addressed was the means and methods by which aircraft for the Ilmavoimat were selected and purchasing decisions were made. This all took some time, but the end result was a fairly major company restructuring that took place in 1933. Kurt Berger was one of those who took some of the blame and he was dismissed from the company (although his services as an advisor were retained). Ylinen was promoted to Construction Manager in 1934, and this together with substantially increased funding and the somewhat ruthless direction of the Chairman of the Board of Directors, Rudolph Walden, who was more than willing to step in and micromanage issues that needed to be addressed – bypassing or overriding VL’s management at times - and who continully emphasised the urgency of the situation and the speed with which projects needed to be completed, resulted in rapid progress and improvements.

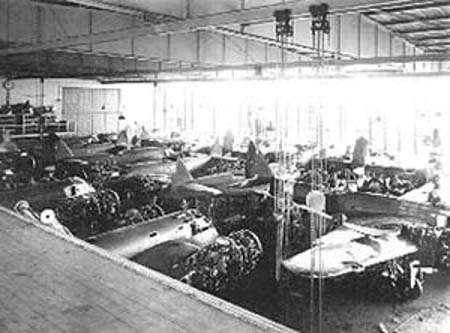

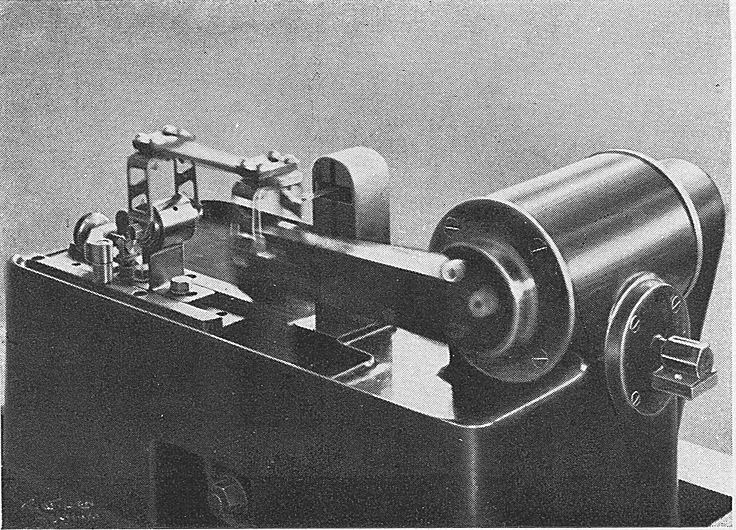

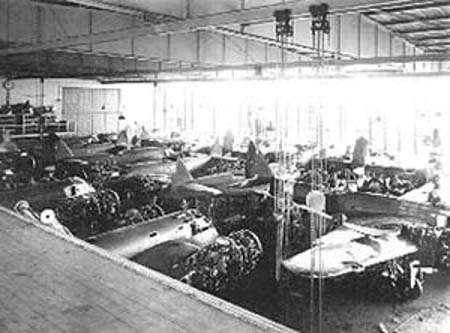

Walden was not a man to accept excuses or tolerate failure and after a number of heads had rolled, progress became rather more rapid. In 1935 Valtion Lentokonetehdas was further re-organized, the works at Suomenlinna and Santahamina were closed and all design and production work was moved to the new facilities that were being built at or near Tampere. In 1936, the new Tampere factory employed 665 persons, but with the planned construction program getting underway, by the end of 1937 some 1,697 persons were employed, by late 1938 this had further increased to approximately 2,500 and by 1939 was somehwhat over 3,250. In addition, by 1939 the State Engine Factory employed some 1,000 personnel and plans were to double the number of personnel. In 1937, Walden implemented a further reorganisation of responsibilities. Valtion Lentokonetehdas would, from August 1937 on, be responsible the construction of new aircraft under license with the design and construction of indigenous aircraft as a secondary function.

Meanwhile, Veljekset Karhumäki (the "Karhumäki Brothers"), who also had a small aircraft construction business as well as a rather larger maintenance concern at Härmälä Airport, would be responsible for the assembly of all imported “built-up” aircraft as well as all the overhaul and repair of military aircraft that could not be performed by the Ilmavoimat Squadron maintenance personnel. An outright grant was given to Veljekset Karhumäki for the construction of additional hangers and maintenance workshops, together with a contract for ongoing maintenance work. At the same time, wartime contingency plans for the dispersal of facilities were drawn up and steps taken to put in place secondary and backup plants. In addition, as of mid-1937, it was becoming clear that the aircraft of the future would no longer be constructed primarily of fabric and wood but increasingly would be part or all-metal construction. Valtion Lentokonetehdas would need to rapidly build up expertise in this technology and Walden ensured steps were taken, including sending Engineers and other personnel abroad, to meet this need (the sending of Ylinen and two other engineers to Berlin to study aircraft engine design and construction was a small part of this program).

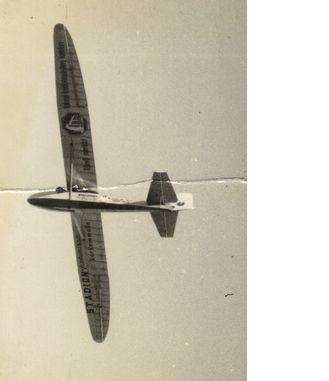

As new aircraft types were purchased and either assembled and maintained or manufactured under license Valtion Lentokonetehdas, Veljekset Karhumäki and Ilmavoimat maintenance personnel all acquired this experience and the expertise of the personnel within the small Finnish aviation industry rose to a very high level. As mentioned earlier, in 1927, the Ilmavoimat had been considering the purchase of Gloster Gamecock Fighters from Britain and on 23 March, 1927 the State Aircraft Factory (VL) received a single Gamecock from England for evaluation. At the same time, IVL had been experimenting with the Berger-designed prototype of the IVL Haukka, the Haukka I. This was built and made its maiden flight on March 17, 1927. This was immediately followed by the VL D.27 Haukka II - a further developed version of the D.26. Two aircraft were manufactured at the aircraft factory at Suomenlinna and in evaluations, the Haukka II turned out to have similar characteristics to the Gamecock, indeed, it proved to be the Gamecock’s equivalent in all regards.

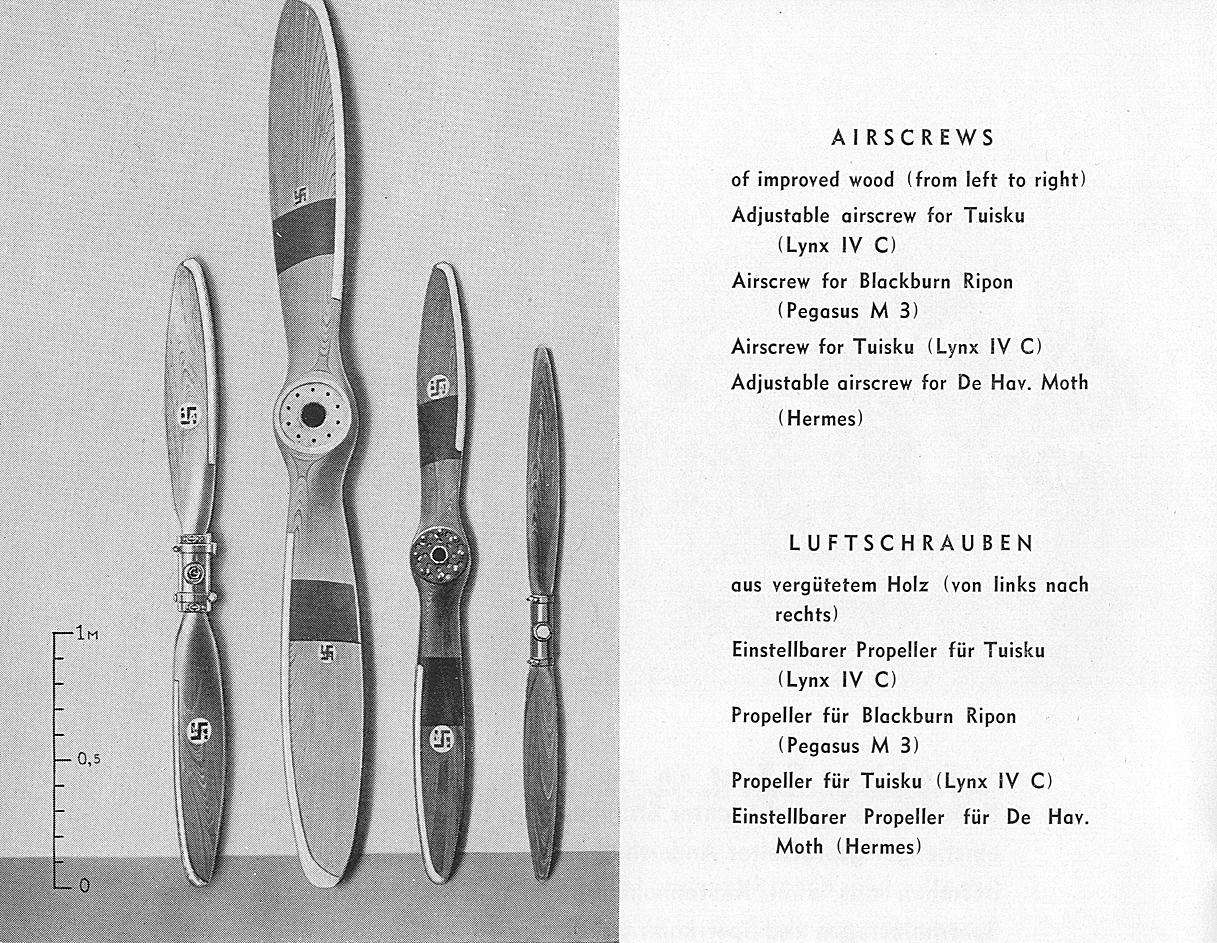

Given the failure of Berger’s previous designs, a perhaps somewhat risky decision was made that the Haukka II would be ordered to equip a single Fighter Squadron, augmenting the single squadron of Martinsyde Buzzard Fighters then in service. An order for 17 aircraft was placed, with the Haukka’s to be manufactured at the VL aircraft factory at Suomenlinna. These were manufactured between 29 Oct, 1928 and 15 May, 1929. A further 23 Haukka’s were ordered in January 1929 and were manufactured between May 1929 and April 1930. In service, the Haukka II proved to be an effective and reliable fighter, well-liked by the Pilots and a good dog-fighter. Another (and this would later be significant) factor in the design and development of the Haukka was that it contributed considerably to the development of aircraft plywood in Finland – a factor that would prove critical later in the 1930’s. It would not be the last indigenous design to go intoproduction, but neither would there be a plethora of Finnish designed and built aircraft – the emphasis still remained in either purchasing aircraft outright, building an imported design under license or a combination of the two.

In the next Post, we will continue with a summary of Valtion Lentokonetehdas’ and the Ilmavoimat’s Purchase and Construction Program between 1927 and the Munich Crisis of 1938, covering each aircraft in detail.

An now - an interim side-bar to the current topic of of Valtion Lentokonetehdas’ and the Ilmavoimat’s Purchase and Construction Program

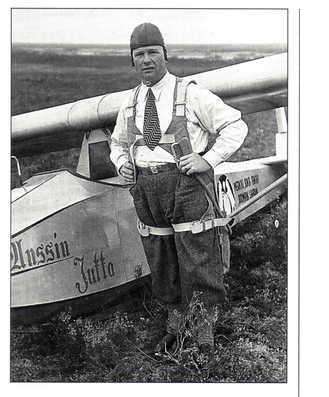

An Interesting Experiment

One of the inspectors of the Valtion Lentokonetehdas (VL) airplane engine workshop in the late 1930’s was Finnish engineer Toivo Jujani Kaario (b. Helsinki, 7 June 1912, d.Tampere, 20 October 1970). Kaario’s father, Hugo Johannes Kaario was also an Engineer, his mother was Iida Maria Appelqvist. The family had four children of whom Toivo was the oldest. Kaario took his matriculation examination in 1930 and completed his military service at the Santahamina factory over 1930-1931. Kaario had an early interest in aviation and at 14 years old he built his first powered aircraft model and had already during his school years, decided to become an airplane designer. With his glider flying experience, Kaario wished to become a Pilot in the Ilmavoimat and he sat Air Force entrance exams, but failed to qualift for pilot training due to poor vision. However, he was selected during his Conscript Service for Reserve Officer training, which he completed successfully, being promoted to lieutenant in July 1931.

In school, his interest in aviation had resulted in his being befriended by Ilmari Jäämaa, editor and writer for a number of different popular science type magazines. In 1929, Kaario had, with classmate Ensio Nuorteva, used a light car to tow one-man gliders. During his Conscript Service, Kaario also became acquainted with a motor transport that operated over the winter sea ice between Santahamina and the inner city of Helsinki. In 1932 Kaario started mechanical engineering courses at the Helsinki University of Technology, graduating as an engineer in December 1936. Following graduation, Kaario was immediately hired by the new and expanding State Aircraft Engine Factory as a service engineer. He was however, together with two other newly hired engineers immediately sent to Germany to study aero-engine design at the Charlottenburg University of Technology in Berlin where he remained for 1937 and 1938. The intention was that these three engineers would then taking leading roles in the new aircraft engine plant in Finland (where currently the bulk of the Engineers were foreigners hired to assist with establishing the factory and train Finnish employees).

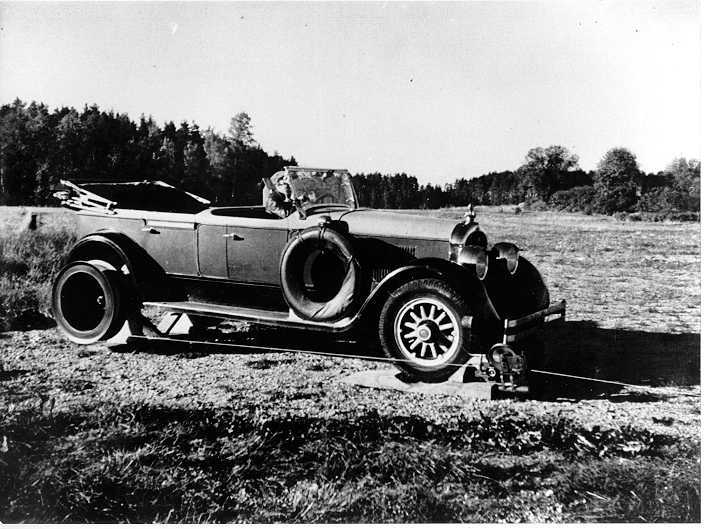

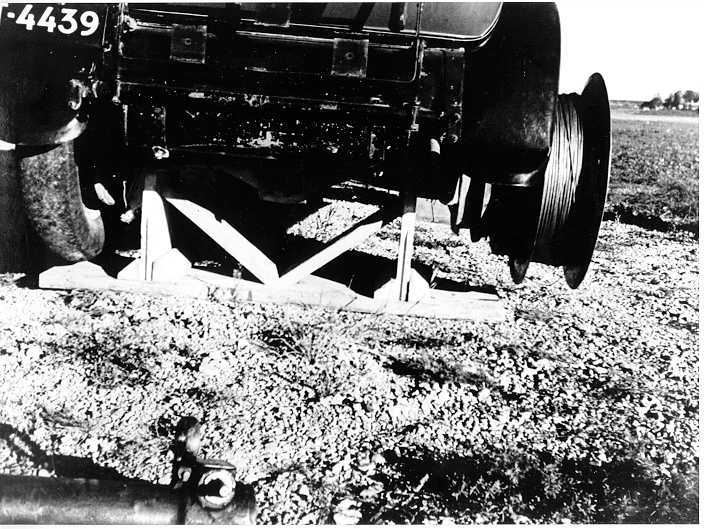

At the start of 1939, Kaario returned to Finland together with his two colleagus and was transferred to the State Aircraft Engine’s new Linnavuori engine plant at Siuro where he was assigned to the aero-engine testing facility. Back in Finland, he now had the time to indulge into what had been a long-time hobby. In 1932, Kaario had come up with the idea of developing a vehicle utilising maavaikutusta (ground effect) and he had actually designed a gound-effect vehicle and built a small working model which worked by generating an air-cushion to support it. Over the winter of 1934-1935 Kaario went on to build the first Pintaliitäjäprototyypin (Pintaliitäjä=Surface Soarer, thus “Prototype Surface Soarer”), which was tested on the ice in January 1935.

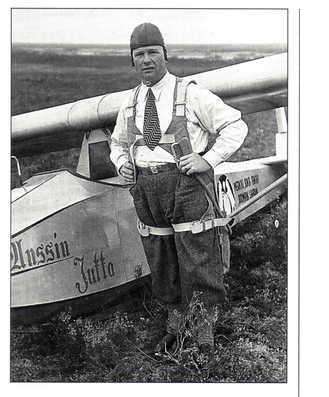

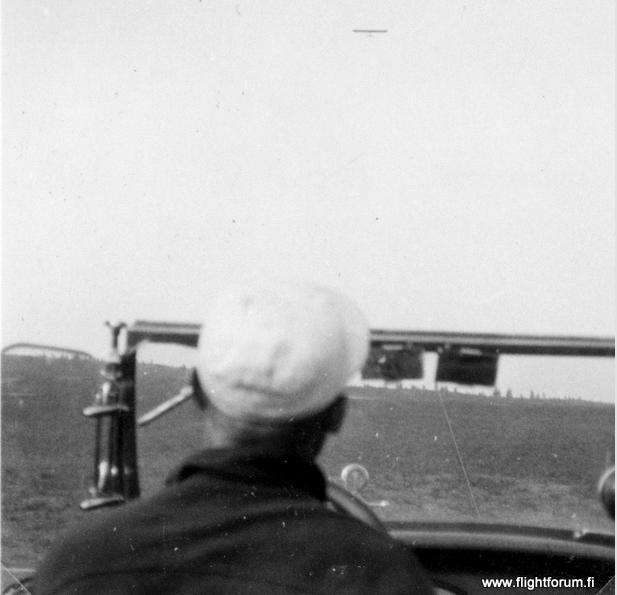

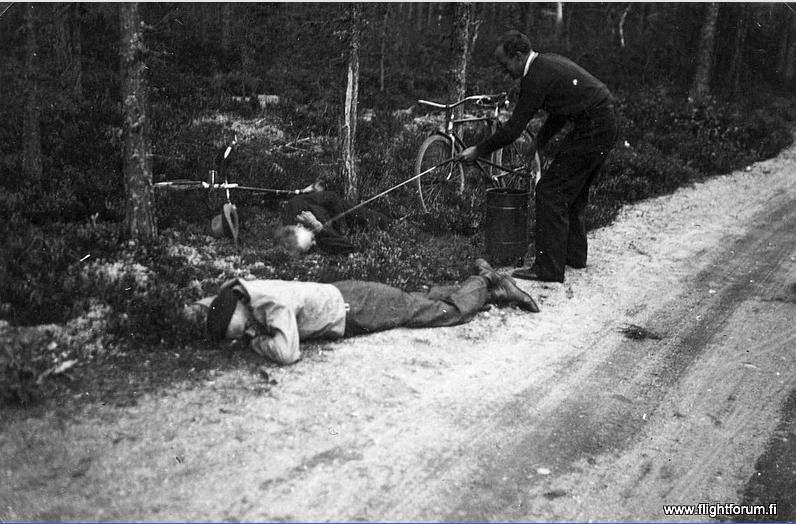

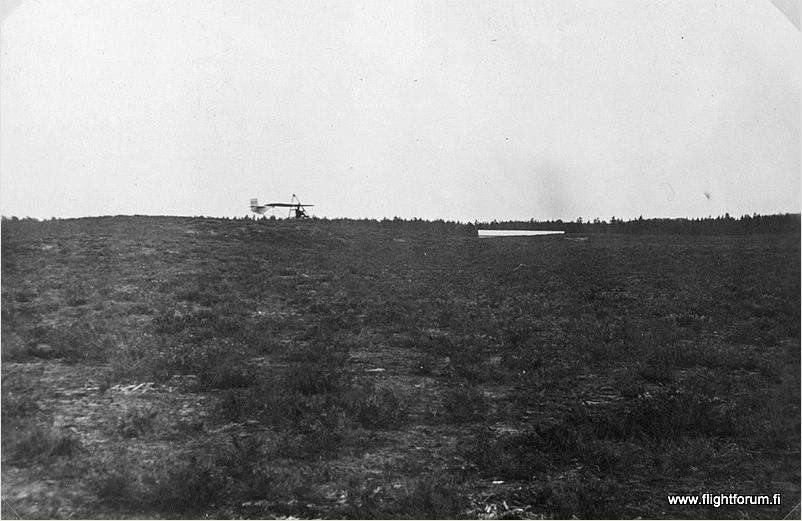

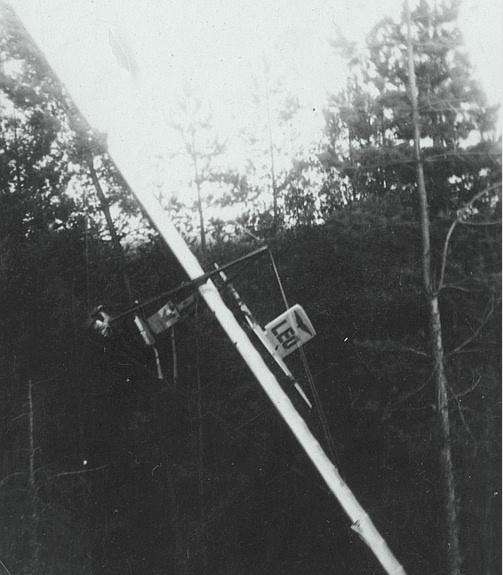

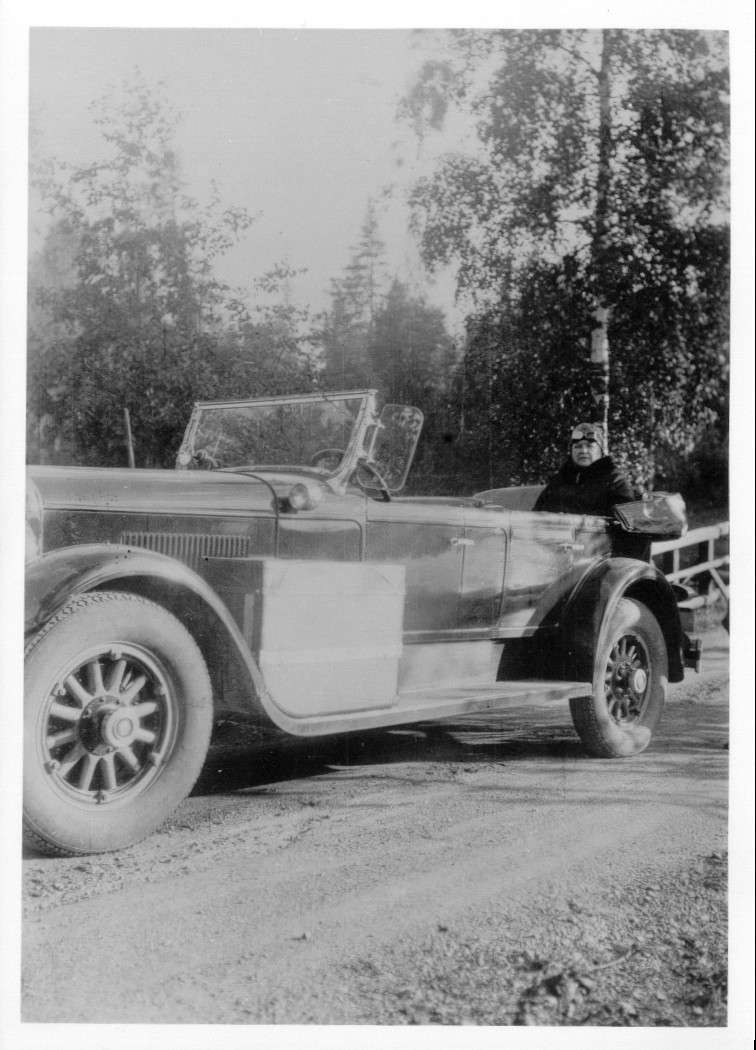

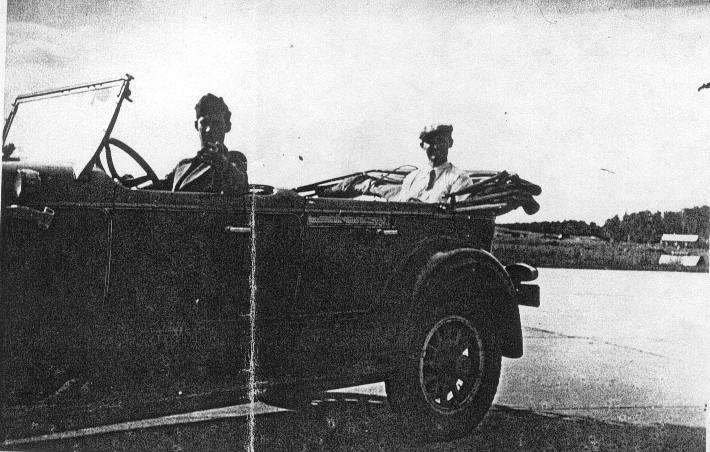

Toivo Kaario on an early Pintaliitäjäprototyypin in mid-1935

Based on experience testing the first prototype, Kaario went on to build a second prototype, Patosiipi No. 2 which he tested over 1935-1936. Kaario began to develop his theories concerning the use of ground-effect and built several models for further tests. As the ground-effect wing of Kaario’s early designs had an almost non-existent ability to block the loss of air being blown down by the propellor, the Patosiipi No. 2 was able to lift, but the ground-effect lift was weak. Kaario continued to experiment through 1936, building a further full-sized prototype powered by a 2-cylinder Harley-Davidson motorcycle engine but this time with a ”skirt” underneath which added to the lift by trapping the high pressure air that had been forced. This device was first tested on land and then on the water and was found to be slower but with more lift over an uneven surface. It was at this point that Kaario had discontinued his research and trials as he had graduated and is spare time in Berlin was largely taken up with his studies. However, he did have some free time....

And Kaario used this time well, bouncing his ideas around with German aviation experts, draw new designs, build and test models and come up with further improvements. In the late 1930’s when Kaario was in Germany, German aviation had been released from the shackles imposed after the defeat of WW1, the Luftwaffe was expanding rapidly, German aviation designers were trying out a variety of new ideas and concepts, some of them out there on the bleeding edge of technology, many of them merely leading edge, and Kaario found himself in the thick of this. His interests led him to make many contacts, and on his return to Finland in January 1939, Kaario had accumulated two years worth of ideas, thoughts and interaction with German aviation experts as well as having constructed and trialled a large number of models. Almost all his spare time was taken up with building and testing models and almost immediately he also began work on Patosiipi No. 8 which had substantially improved lift and air flow properties. At this stage a number of fellow workers at the State Aircraft Factory had become interested in his project and provided voluntary assistance. Work on Patosiipi No. 8 progressed rapidly tilizing a 53hp Porsche engine and before the snow was off the ground in the Spring of 1939, the device was first tested on land beside the Härmälä airport and then on the water at Siuro. The main problems experienced were vibration when driving on uneven ground and the inability of the prototype to drive over obstacles more than 20-cm-high. Sometimes serendipity plays its part in events. It was the testing beside Härmälä airport that inadvertantly led to far more rapid progress than Kaario had anticipated. Major-General Somersalo had been attending a meeting at the Airport whic had run late. On leaving, he happened to see the group working on Patosiipi No. 8 and stopped to watch as a test run was carried out, with the device reaching some 80kph while carrying two people. Intrigued, Somersalo had walked over to the group and started asking questions. At midnight, the entire group and Somersalo were still at the Airport with Kaario running an impromptu design review.

Two days later, Kaario and his team of volunteers found themselves doing a presentation to Somersalo, the head of the Merivoimat, Väinö Valve, the comanding officer of the Marine Jaegers, a small group of technical Officers and a couple of rather tough looking individuals in nondescript Maavoimat uniforms without any rank or branch identification. Kaario seized the opportunity and over a single day, he outlined the concepts and ideas he had put together while in Germany, starting with plans for a 100 ton Pintaliitäjä intended for transport on the Baltic Sea and with a cruising speed of 100-120kph, then moving on to concepts for a Fast Torpedo and Minelayer Pintaliitäjä and a High Speed Infantry Assault Pintaliitäjä. The ”ground effect” concept was explained in detail, and then demonstrated using Patosiipi No. 8, and Kaario’s ideas on how this could better be utilised were also explained (Kaario was perhaps the first to conceive of using a ”skirt” to trap air, rather than simply using ground-effect).

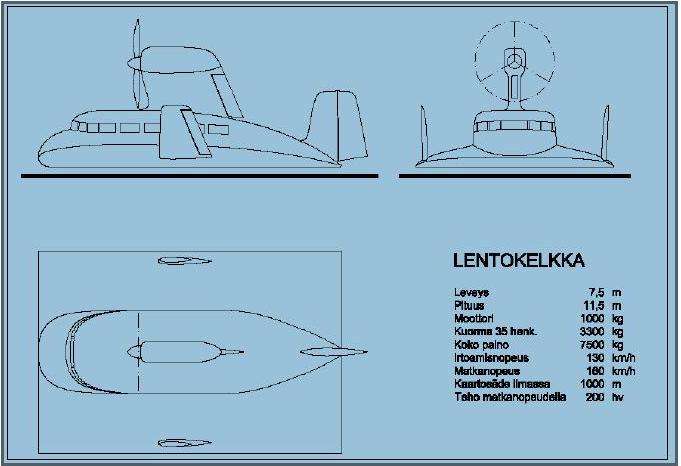

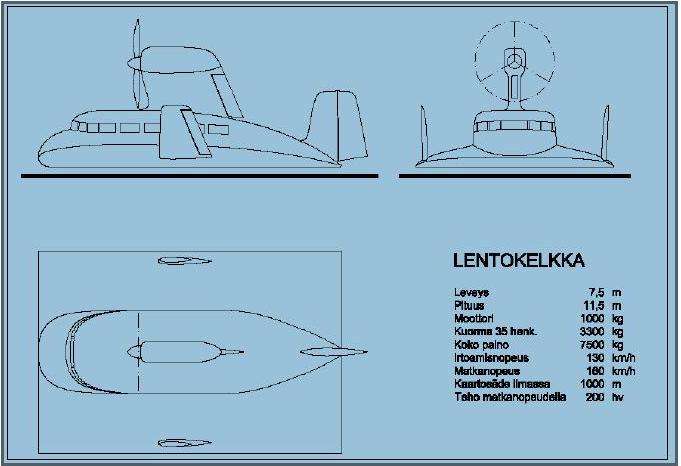

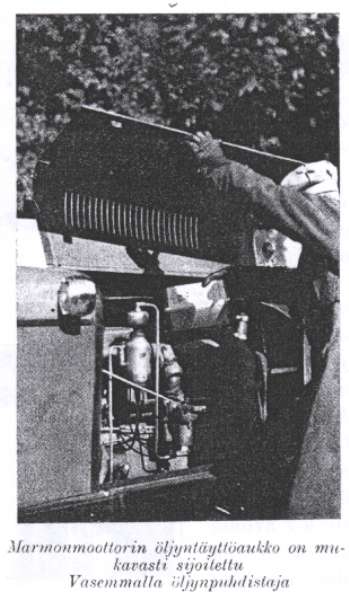

Line Drawing of Pintaliitäjä-Craft proposed by Kaario in Spring 1939

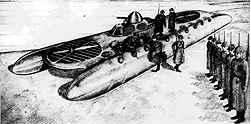

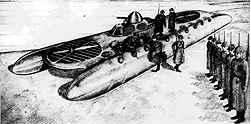

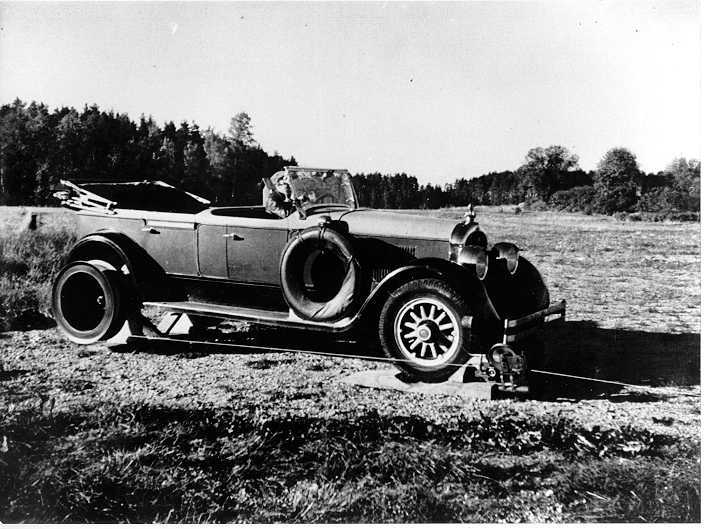

Rough Sketch of Infantry Assault Pintaliitäjä-Craft as proposed by Kaario in Spring 1939

The next morning he was summoned to the office of the Manager to find, not the Manager but the Commanding Officer of the Merivoimat, Väinö Valve. After a short and to the point discussion, Valve asked Kaario if he would take on a position as leader of a design and development team tasked with turning his Pintaliitäjä concept into a viable military weapon within a 12 month period. Adequate resourcing would be provided and the project would have the full backing of the Merivoimat. Kaario agreed. Almost immediately, a team was assembled and design work began for a full-size protoype of the Fast Torpedo and Minelayer Pintaliitäjä. The first prototype, maintaining the numbering sequence Kaario had initiated in 1932 was designated P-9, and had a very simple design which consisted of an elongated oblong shape made up two wooden catamaran hulls and powered by three aircraft engines using what we would now call a chamber configuration design. Two Mercury aero-engines were installed horizontally in the funnel-shaped wells on the platform which connected the catamaran hulls together. The third engine, also a Mercury, was placed in the aft part of the craft on a removable four-strut pylon. An air cushion was produced by the horizontally-placed engines. P-9 was designed and built over a one week period and was immediately trialled, achieving a speed of 70 knots, or about 130 kilometers per hour.

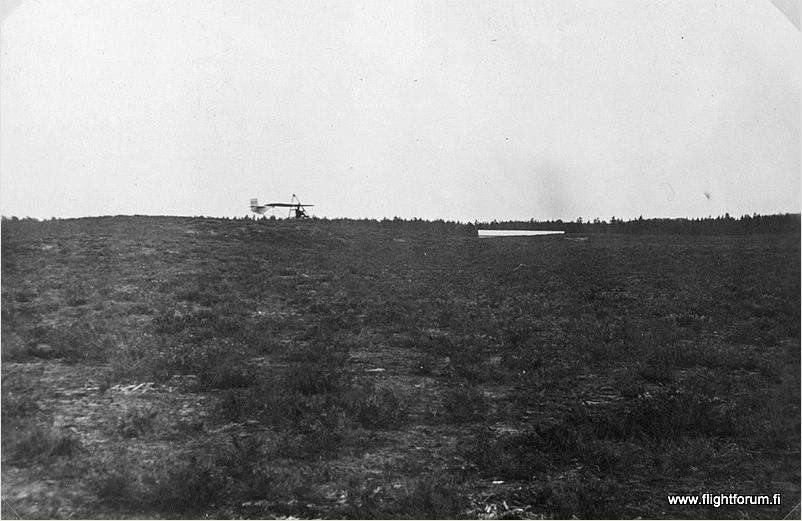

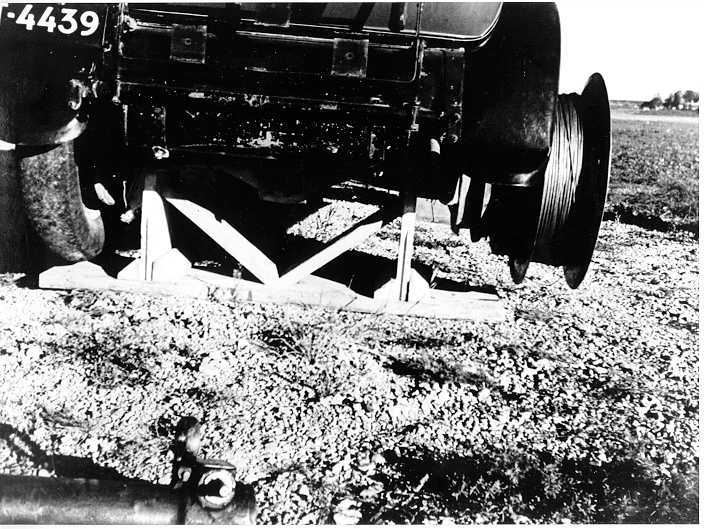

P-9 during initial trials in Spring 1939- the Red Star and ”CCCP” were painted on the sides to confuse any Observers, as it was known that the USSR was conducting trials on a similar type of craft designed by a Soviet engineer, Vladimir Levkov. It was hoped that any sightings of the Finnish craft would be confused with the Soviet Navy craft that had been observed carrying out trials.

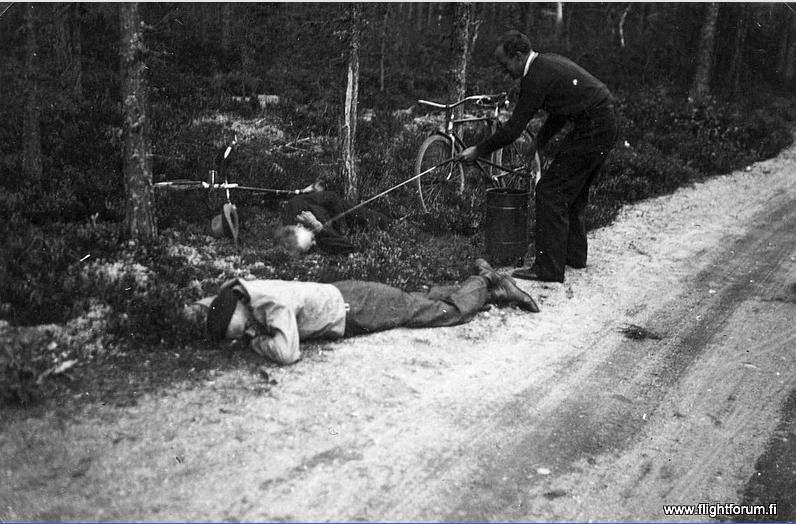

The tests lasted for 10 days and at that time nobody other than Kaario and his small team of volunteers had any experience in operating such vehicles. Overwater runs were performed using all three engines running simultaneously, with the trials conducted in both calm and windy weather, crosswind and downwind, over flat shore and over swampy areas covered with sedge. Once the hovercrafts engines failed and the vehicle landed in a deep swamp. However, as soon as the engines were restarted, the boat ascended and recovered itself from the swamp. The maximum speed in the first runs was approximately 60 knots but in later tests 70 knots was easily reached and according to the P-9 test commander, a Merivoimat Fast Torpedo Boat commander, this was not on full power. Trial results of this first prototype hovercraft were acknowledged as very satisfactory. It was indicated in the report that the “principle for surface-soarer vehicles has been proven feasible.” This report was approved by the Commander of the Merivoimat, who directed that the Naval Construction Plan should encompass the production of two types of such skimming boats: one to be used as a fast attack torpedo craft and the other as a marine landing craft. Emergency Funds were allocated and the project was given the highest priority with a direction that three prototypes of each were to be constructed and completed by the end of summer 1939. This was a highly aggressive timetable, but one that the team worked day and night to meet.

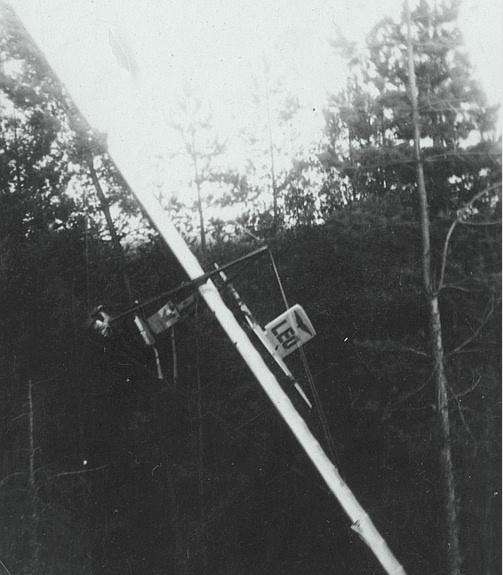

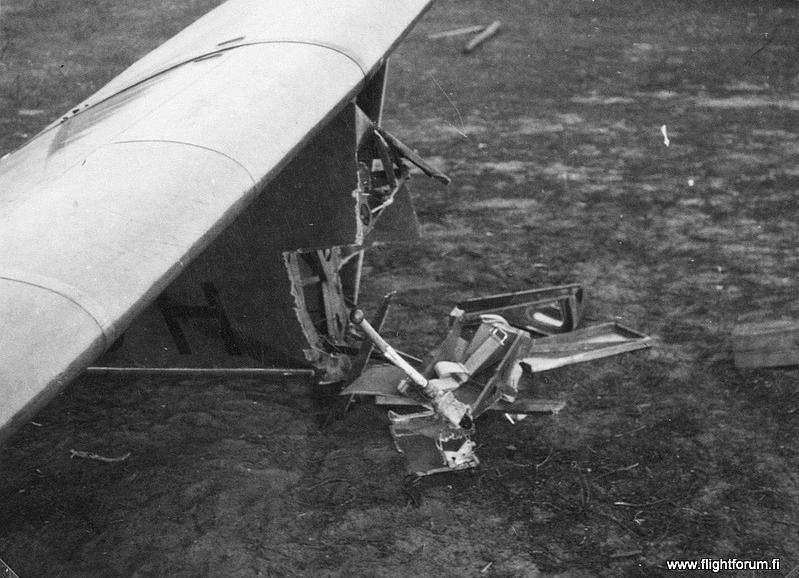

P-10 at rest during a break in her initial trials P-10 had been designed over a four week period and a prototype was put together by mid-July 1939.

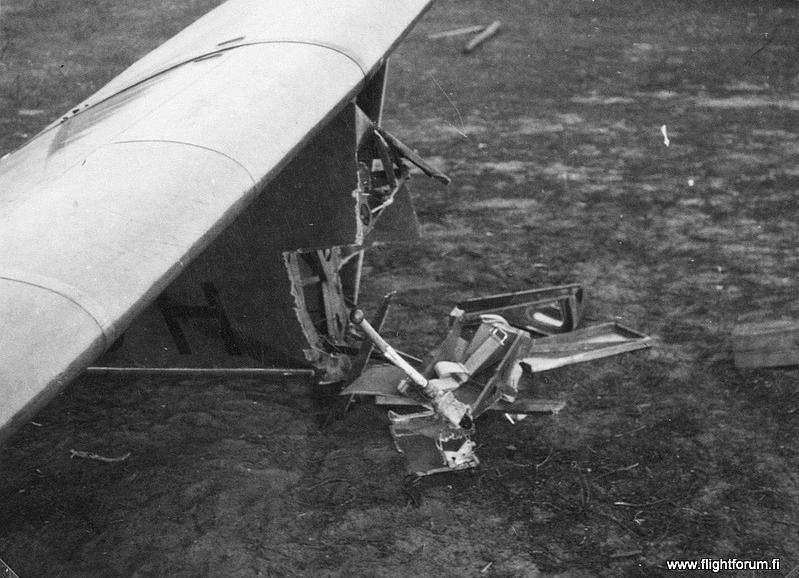

Performance Trials of P-10 on the Gulf of Finland, Summer of 1939. ”CCCP” was painted on the sides to confuse any Observers, as it was known that the USSR was conducting trials on a similar type of craft designed by a Soviet engineer, Vladimir Levkov. It was hoped that any sightings of the Finnish craft would be confused with the Soviet Navy craft that had been observed carrying out trials.

Building on knowledge gained from the P-10, a full-metal (duralumin) fast torpedo and infantry assault craft, designated P-11 was built in late summer 1939. The craft had a streamlined shape, in the midship area there was a streamlined pilot house/cabin for the pilot, mechanic and radio operator followed by a troop compartment, two turret (aircraft turrets were used, as had been done with some of the patrol torpedo boats) machine-gun mounts were installed on either side and slightly aft of the pilot-house and there was an aft mounted rear-facing 20mm cannon for AA protection. Directional control was provided by two large tail fins. Torpedo attachment points were arranged on either side of the troop compartment and the craft could also carry eight depth charges. The P-11 could surmount sandy strips, bogs, ice and rough seas, but was unstable during high speed turns. Regardless, a decision was made that it should go into production and by November 1939, the Merivoimat had 21 experimental air-cushion dual-purpose P-11 Pintaliitäjä-boats (High-Speed Torpedo Boats and Assault Craft) in service. The P-11 had a tonnage of 8.6-11.3 t, a crew of 7 men, a length of 24m, a width of 5.4 m, was armed with 2x12.7mm machineguns and 1x20mm Hispano-Suiza 20mm Cannon, carried two torpedoes, was powered by 2x1000hp Hispano-Suiza engines and could reach a top speed of 80 knots (approx 160kph).

As the Winter War broke out, Kaario’s team worked on manufacturing additional P-11 Pintaliitäjä-boats and repairing these that had been damaged while Kaario next began to work on an improved P-11 design as well and then, as this changed radically, it became the design for a larger and longer-ranged P-12 Pintaliitäjä-boat. With more P-11’s having been built and actually being used in operations during the early weeks of the Winter War, Kaario realised the craft had some serious shortcomings. Both good and discouraging reports were coming from the Merivoimat. The discouraging reports stated that pressure under the Pintaliitäjä-boats was low due to air escape through the vessels open ends, which reduced the load-carrying capacity; spray produced by the powerful engines limited visibility, the Pintaliitäjä-boats operations were limited to sea state 4 or less amd the impact of the Pintaliitäjä-boats with waves changed the settings of the louvres and occasionally damaged them. The engines also had problems with stalling when water penetrated into the exposed carburetors, and since the engines were positioned horizontally, they were not sufficiently air-cooled and would often overheat if run for long periods of time. Despite this, the Pintaliitäjä-boats had proved highly effective in combat due larely to their unbelievably high speeds.

Kaario and his design team worked 16 hour days working to rectify these problems, often sleeping under their desks in the ex-VL Suomenlinna factory building that was now their base. In the end, the ability of the P-11 design to cope with high speed turns seemed to improve with a substantial widening of the boat, first to 10m and then to 15m. As for lift, Kaario initially experimented with the building of a working model that demonstrated that by pumping air into a narrow tunnel around the perimeter of the underneath of the craft, it would flow towarda the center, creating a more effective air cushion. This peripheral jet would allow the air pressure to build enough to equal the weight of the craft and, since the air would be trapped, the pressure would elevate the craft off the surface upon which it traveled. By contrast, the P-11 utilised ground-effect, basically provided lift by using a propellor fan to force air from the deck down into the chamber between the two catamaran sides, which meant that air had to be continually pumped down to replace the air that escaped. After successfully trialling a model demonstrating that his new “air cushion” theory worked, Kaario redesigned P-12 incorporating a number of other modifications, a subject we shall return to after the Winter War.

OTL Note: Historically, Toivo Juhani Kaario was a Finnish engineer and inventor, who in the 1930s started working on prototypes of air cushion vehicles. Kaario is considered to have designed and built the first functional ground effect vehicles, but his invention did not receive sufficient funds for further development. Also, in this ATL I have shifted the dates by a couple of years to fit the scenario. But all else aside, Kaario WAS the first in the world to design and build functional ground effect vehicles and the Soviet engineer, Vladimir Levkov, followed his efforts as closely as was possible before building his pre-WW2 combat hovercraft for the USSR…… Toivo Kaario died at the age of 58 after a short illness in October 1970. He is buried at Tampere in the Kalevankangas Cemetery.

And now, back to Valtion Lentokonetehdas

Before we run through a history of aircraft construction by Valtion Lentokonetehdas, we’ll take a more indepth look at the new factory and at one of the key engineers – Arvo Ylinen.

Arvo Johannes Ylinen (b. Yläne, Southwest Finland on 5 March 1902 – and died 27 July 1975) was an aeronautical engineer and late a Professor of Aeronautical Engineering. His father was Juho Ylijaakkola and his mother was Sofia Emerentia Uusitalo. Arvo Ylinen graduating from high school in Turku came in 1923, attended University and graduated in 1930 with a Master of Science ”with Distinction” in Engineering, which was then very rare. In the same year he completed the CDI's military technical department graduate course. He studied aviation engineering at the Charlottenburg Technical School of the Berlin University of Technology over 1930-31 and later completed a doctoral thesus, which he defended at TKK in 1938. His dissertation was the first aircraft technology thesis completed in Finland.

He joined IVL at Suomenlinna, first working as a Design Engineer from 1932 to 1933. He was soon promoted to Office and Drawing Manager, a position he held from 1933 to 1934. In 1934 he was married to Lea Maria Hietarinta, a Medical Doctor. He held the position of Construction Manager from 1934 to 1937 and Technical Director from 1937-1940. He became the first TKK Professor of Aeronautical Engineering in 1940, a position he held until 1956. At the same time, he continued to serve as an Advisory Engineer to Valtion Lentokonetehdas from 1940 to 1949. From 1956 to 1967 he was Professor Engineering whilst also working as a Laboratory Director for VTT from 1952 to 1956. He chaired the National Defence Scientific Advisory Committee for 4 years from 1 October 1961. He received numerous awards and wrote and published many books and articles and held the rank of Lieutenant Colonel in the Army. Arvo Ylinen died on 27 July 1975.

Arvo Ylinen was instrumental in the major achievements of ”success years” of Valtion Lentokonetehdas, holding the key positions of Construction Manager from 1934 to 1937 and Technical Director from 1937-1940, the period in which VL expanded its capacity dramatically and manufactured the aircraft that would be critical to Finland’s survival in the Winter War. Ylinen, the Manager of Valtion Lentokonetehdas (xxx), Rudolph Walden as Chairmain of VL’s Board of Directors and Major-General Somersalo were between them the key figures responsible for increasing aircraft production, directing the selection and mix of aircraft and making sometimes risky and at times also radical decisions which in turn enabled the Ilmavoimat to outclass and outfight their opponents at every stage of the Winter War and through WW2. Even towards the end of WW2, aircraft such as the Ilmavoimat’s Fokker G1 and the Heinkel He112 Fighters were, thanks to continual upgrades, still effective fighters capable of more than holding their own. In the Winter War, they proved to be devastatingly effective, as we will see.

Returning now to the Valtion Lentokonetehdas factories, the works at Suomenlinna and Santahamina continued to be utilised through the first half of the 1930’s, with some limited construction of indigenous designs, construction of foreign aircraft under licenses and the assembly of aircraft purchased from foreign suppliers. The early years of IVL and VL had seen some mistakes – not the least of which had been the disastrous purchase of the Koolhoven FK.31 from the Netherlands virtually ”on spec”. At the same time, relations between the Commander of the Ilmavoimat, Major Somersalo and the General Staff had not improved to any great extent. As you may recall from an earlier Post, in 1924 the British Maj. Gen. Walter Kirke and a small team of British military advisors had carried out a Defence Review and made a number of recommendations on Finland’s defences, including recommendations that the Ilmavoimat concentrate on a float-plane based development plan. At the time this plan had been strongly opposed by the Commander of the Ilmavoimat, Major Somersalo. However, Somersalo’s views had been overruled by the General Staff, who were more inclined to take account of the recommendations of the so-called British ”experts” rather than those of a relatively junior Finnish Officer. Somersalo however had soldiered on despite the many obstacles in his path, doing his best to work around the limitations imposed by the Kirke Review, the views of the General Staff and the relative independance of I.V.L, which also caused many problems.

Relations between the General Staff and the Ilmavoimat Commander in 1930 were, as we have mentioned, not of the best. Major Somersalo did his best to work with what he had, but the funds allocated to the Ilmavoimat were limited, within the military hierarchy he was a fairly junior office and while serving as Commander of the Air Force, he had not been promoted – the Maavoimat was by far the larger and more influential of the services, commanding the lions share of the limited military budget through the 1920’s (albiet with increased naval spending in the latter years of the decade) and many of the decisions made were out of his hands and not subject to his control or influence. And the shift in control of Valtion Lentokonetehdas from the Ilmavoimat to the Ministry of Defence in 1928 had been just one more issue he had to face. Somersalo however persisted in the face of adversity, continuing to emphasize the development of a mix of capabilities, demanding the development of combat flying skills from his squadrons, continually emphasising the need for close support teamwork with the Maavoimat (Army) and Merivoimat (Navy) and doing his best to workaround the limitations imposed by the recommendations of the Kirke Review and the views of many in the Maavoimat, who at best considered the Ilmavoimat something of an irrelevance – useful perhaps for reconnaisance or artillery spotting but not much else. There were of course exceptions – the theorists in the Maavoimat making up most of these – but they tended to be the younger and more junior officers.

And then, in 1930 the General Staff set up a Restructuring Committee to look at the Ilmavoimat and aircraft purchasing and construction. The Committee completed their report in 1931 and stated among other conclusions that the views of the British Advisors from 1924 were obsolete. As a result the General Staff decided to improve their aviation warfare skills knowledge and appointed their own air defense officer. Lieutenant-Colonel Aarne Snellman was appointed to the post and almost immediately harshly criticized the constraints and operating limitations that had been imposed on the Ilmavoimat and expressed support for the views of the Commander of the Ilmavoimat, Major Somersalo. It was at this point, in March 1931 that Mannerheim was appointed to chair the Defence Council and also commissioned as overall Comander-in-Chief of the Armed Forces with Rudolph Walden appointed Minister of Defence in the All-Party Consensus of 1931. Mannerheim immediately initiated the 1931 Military Review, which was completed some six months later – and it was a six month period of heated and sometimes vitriolic debate within the Finnish Armed Forces.

Aarne Snellman: (2. December 1894 - 28 April 1940 Helsinki): Snellman's father, Wilhelm Snellman was a district physician, his mother was Alexandra Sittkoff. Born on 1894, he matriculated from the Savonlinna Real Lyceum in 1912 and joined the Savo Students' Association. He continued his studies over the years 1912-1914 at the University of Helsinki Faculty of Philosophy and Economics and completed a first degree in Agriculture and Forest Management. He volunteered for the Finnish Jaegers and was awarded the German Iron Cross (Gruppenführer, JP27, awarded 1/26/1917). During the Finnish Civil War, Jaeger-Captain Snellman commanded Artillery Brigade 3. In 1920 he attended the French Military Pilots' School (Ecole d'Aviation Istres) and in 1921 he completed Finnish Pilot training (it was this early aviation background that led to Snellman being appointed General Staff Air Defense Officer).

He completed the Suojeluskuntas Officers course in 1926 and War College training over 1926-27. In 1927 he married Hildegund von Numersin. From 1934 to 1938 he served as Military Attache in Germany, from 1938-1939 he was the Commanding Officer, 3rd Field Artillery Regiment and over 1939 to early 1940 he was the Commanding Officer, Artillery, IV Corps. He was appointed Acting General Officer Commanding 12th Division following the death of the Division Commander in action, and after a replacement was found he took over as General Officer Commanding 17th Division. Colonel Aarne Snellman, commander of 17th Division, was seriously wounded when Soviet aircraft bombed his command post at Vaaseni on 13 April 1940. Promoted to Major-General on 26 April 1940, he died of wounds two days later.

OTL Note: real date of death was 26 April 1942 – events otherwise occurred as described. Some command periods adjusted, in reality he commanded these Divisions during the Continuation War.

For the Ilmavoimat and for Valtion Lentokonetehdas, the consequences of the 1931 Military Review were far-reaching, if sometimes slow to take effecxt. The views of the Restructuring Committee and Snellman’s report of 1931 as well as contributions from Somersalo and other Ilmavoimat officers were rolled into the 1931 Military Review, and having kept abreast of military affairs, Mannerheim and Walden were no strangers to the issues. Among Mannerheim’s first steps were the promotion of Somersalo to Lieutenant Colonel on 10-October-1931 (and to full Colonel on 8 September 1932 and then to Major-General in 1933 – a rapid rise indeed), the public expression of full support for Somersalo and a demand for immediate plans to be completed for the expansion both in capabilities and size for the Ilmavoimat and immediate financial budgetary arrangements allowing for the purchase of additional aircraft in 1931 and 1932. The other step (not quite so immediately) Mannerheim took was to change the management of Valtion Lentokonetehdas – on 1 January 1932, Engineer Erkki Mäkinen was appointed as Managing Director from among 24 applicants and Rudolph Walden became Chairman of the Board of Directors, giving him immediate oversight. The move of the Valtion Lentokonetehdas factory to Tampere was also approved at this time, although in this case it was Walden’s views on the location of the factory that carried the day. This incidentally, tended to be the general tenor of decisions taken by the Defense Triumvirate – Mannerheim tended to win the straight-out military decisions, Walden the industrial decisions and Ryti the financial. Where politics intruded, the views and influence of Vaino Tanner inevitably came into play, resulting at times in some interesting (but almost always practical) compromises.

We have already looked at the early attempts of IVL to design and build indigenous aircraft with the Berger designs for the C.24 and C.25, as well as the Kurki (“Järvinen's crate"). As a result of these failures, aircraft purchases had concentrated on either the purchase of built-up aircraft or the construction of imported designs built under license. The 1931 Military Review envisaged this mix continuing. It was considered too risky to rely entirely on aircraft purchased from foreign suppliers – in the event of war access to these would in all likeliehood be cut off. A domestic manufacturing capacity was needed, and it needed to be adequate to cope with the demands of the military in a war-time scenario. Stategically, attention was also paid to building up the ability to manufacture key components within Finland – hence the emphasis on the engine manufacturing capacity which resulted in the setting up first of the State Aircraft Factory (manufactiring Bristol Mercury and Rolls Royce Merlin engines under license) and then of the Tampella-Hispano-Suiza Factory (maunfacturing Hispano-Suiza aircraft engines). Likewise, there was a parallel emphasis on building up gun-manufacturing capacity – one component of which was the Hispano-Suiza 20mm cannon manufacturing plant.

Earlier mistakes, such as the purchase of the Koolhoven FK.31 from the Netherlands, the failure of the C.24, C.25 and Kurki projects were reviewed and initiatives currently underway which were experiencing problems such as the manufacturing of the Ripons were also looked into. A further issue addressed was the means and methods by which aircraft for the Ilmavoimat were selected and purchasing decisions were made. This all took some time, but the end result was a fairly major company restructuring that took place in 1933. Kurt Berger was one of those who took some of the blame and he was dismissed from the company (although his services as an advisor were retained). Ylinen was promoted to Construction Manager in 1934, and this together with substantially increased funding and the somewhat ruthless direction of the Chairman of the Board of Directors, Rudolph Walden, who was more than willing to step in and micromanage issues that needed to be addressed – bypassing or overriding VL’s management at times - and who continully emphasised the urgency of the situation and the speed with which projects needed to be completed, resulted in rapid progress and improvements.

Walden was not a man to accept excuses or tolerate failure and after a number of heads had rolled, progress became rather more rapid. In 1935 Valtion Lentokonetehdas was further re-organized, the works at Suomenlinna and Santahamina were closed and all design and production work was moved to the new facilities that were being built at or near Tampere. In 1936, the new Tampere factory employed 665 persons, but with the planned construction program getting underway, by the end of 1937 some 1,697 persons were employed, by late 1938 this had further increased to approximately 2,500 and by 1939 was somehwhat over 3,250. In addition, by 1939 the State Engine Factory employed some 1,000 personnel and plans were to double the number of personnel. In 1937, Walden implemented a further reorganisation of responsibilities. Valtion Lentokonetehdas would, from August 1937 on, be responsible the construction of new aircraft under license with the design and construction of indigenous aircraft as a secondary function.

Meanwhile, Veljekset Karhumäki (the "Karhumäki Brothers"), who also had a small aircraft construction business as well as a rather larger maintenance concern at Härmälä Airport, would be responsible for the assembly of all imported “built-up” aircraft as well as all the overhaul and repair of military aircraft that could not be performed by the Ilmavoimat Squadron maintenance personnel. An outright grant was given to Veljekset Karhumäki for the construction of additional hangers and maintenance workshops, together with a contract for ongoing maintenance work. At the same time, wartime contingency plans for the dispersal of facilities were drawn up and steps taken to put in place secondary and backup plants. In addition, as of mid-1937, it was becoming clear that the aircraft of the future would no longer be constructed primarily of fabric and wood but increasingly would be part or all-metal construction. Valtion Lentokonetehdas would need to rapidly build up expertise in this technology and Walden ensured steps were taken, including sending Engineers and other personnel abroad, to meet this need (the sending of Ylinen and two other engineers to Berlin to study aircraft engine design and construction was a small part of this program).

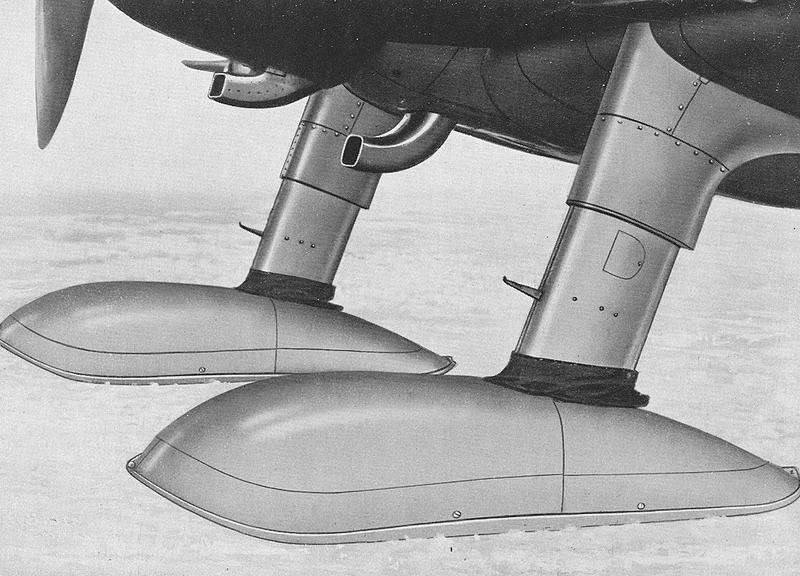

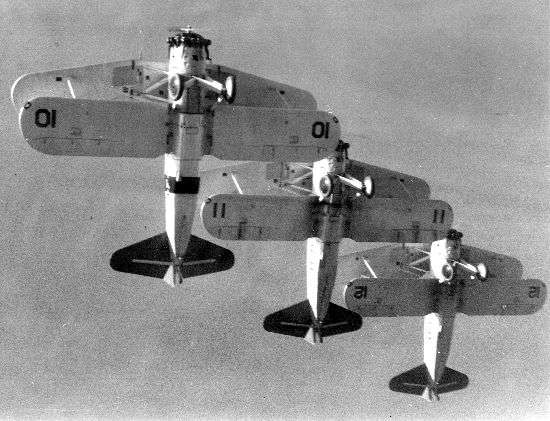

As new aircraft types were purchased and either assembled and maintained or manufactured under license Valtion Lentokonetehdas, Veljekset Karhumäki and Ilmavoimat maintenance personnel all acquired this experience and the expertise of the personnel within the small Finnish aviation industry rose to a very high level. As mentioned earlier, in 1927, the Ilmavoimat had been considering the purchase of Gloster Gamecock Fighters from Britain and on 23 March, 1927 the State Aircraft Factory (VL) received a single Gamecock from England for evaluation. At the same time, IVL had been experimenting with the Berger-designed prototype of the IVL Haukka, the Haukka I. This was built and made its maiden flight on March 17, 1927. This was immediately followed by the VL D.27 Haukka II - a further developed version of the D.26. Two aircraft were manufactured at the aircraft factory at Suomenlinna and in evaluations, the Haukka II turned out to have similar characteristics to the Gamecock, indeed, it proved to be the Gamecock’s equivalent in all regards.

Given the failure of Berger’s previous designs, a perhaps somewhat risky decision was made that the Haukka II would be ordered to equip a single Fighter Squadron, augmenting the single squadron of Martinsyde Buzzard Fighters then in service. An order for 17 aircraft was placed, with the Haukka’s to be manufactured at the VL aircraft factory at Suomenlinna. These were manufactured between 29 Oct, 1928 and 15 May, 1929. A further 23 Haukka’s were ordered in January 1929 and were manufactured between May 1929 and April 1930. In service, the Haukka II proved to be an effective and reliable fighter, well-liked by the Pilots and a good dog-fighter. Another (and this would later be significant) factor in the design and development of the Haukka was that it contributed considerably to the development of aircraft plywood in Finland – a factor that would prove critical later in the 1930’s. It would not be the last indigenous design to go intoproduction, but neither would there be a plethora of Finnish designed and built aircraft – the emphasis still remained in either purchasing aircraft outright, building an imported design under license or a combination of the two.

In the next Post, we will continue with a summary of Valtion Lentokonetehdas’ and the Ilmavoimat’s Purchase and Construction Program between 1927 and the Munich Crisis of 1938, covering each aircraft in detail.

An now - an interim side-bar to the current topic of of Valtion Lentokonetehdas’ and the Ilmavoimat’s Purchase and Construction Program

An Interesting Experiment

One of the inspectors of the Valtion Lentokonetehdas (VL) airplane engine workshop in the late 1930’s was Finnish engineer Toivo Jujani Kaario (b. Helsinki, 7 June 1912, d.Tampere, 20 October 1970). Kaario’s father, Hugo Johannes Kaario was also an Engineer, his mother was Iida Maria Appelqvist. The family had four children of whom Toivo was the oldest. Kaario took his matriculation examination in 1930 and completed his military service at the Santahamina factory over 1930-1931. Kaario had an early interest in aviation and at 14 years old he built his first powered aircraft model and had already during his school years, decided to become an airplane designer. With his glider flying experience, Kaario wished to become a Pilot in the Ilmavoimat and he sat Air Force entrance exams, but failed to qualift for pilot training due to poor vision. However, he was selected during his Conscript Service for Reserve Officer training, which he completed successfully, being promoted to lieutenant in July 1931.

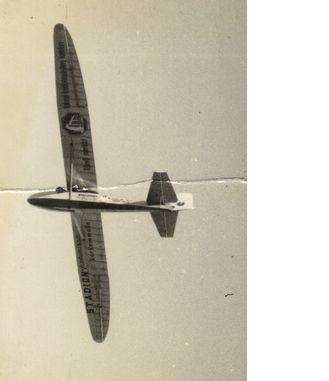

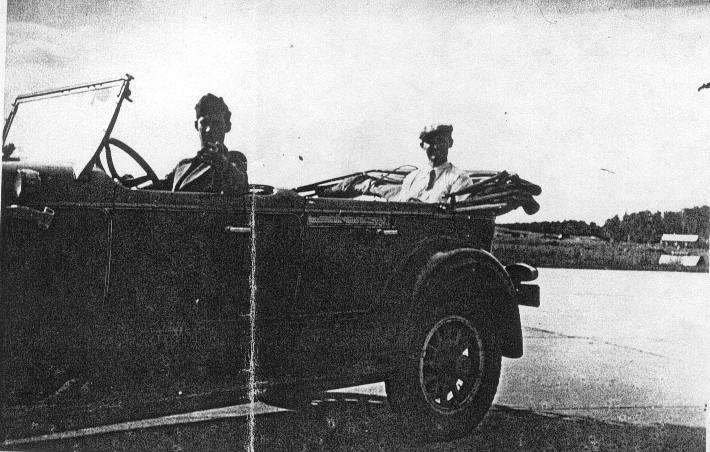

In school, his interest in aviation had resulted in his being befriended by Ilmari Jäämaa, editor and writer for a number of different popular science type magazines. In 1929, Kaario had, with classmate Ensio Nuorteva, used a light car to tow one-man gliders. During his Conscript Service, Kaario also became acquainted with a motor transport that operated over the winter sea ice between Santahamina and the inner city of Helsinki. In 1932 Kaario started mechanical engineering courses at the Helsinki University of Technology, graduating as an engineer in December 1936. Following graduation, Kaario was immediately hired by the new and expanding State Aircraft Engine Factory as a service engineer. He was however, together with two other newly hired engineers immediately sent to Germany to study aero-engine design at the Charlottenburg University of Technology in Berlin where he remained for 1937 and 1938. The intention was that these three engineers would then taking leading roles in the new aircraft engine plant in Finland (where currently the bulk of the Engineers were foreigners hired to assist with establishing the factory and train Finnish employees).

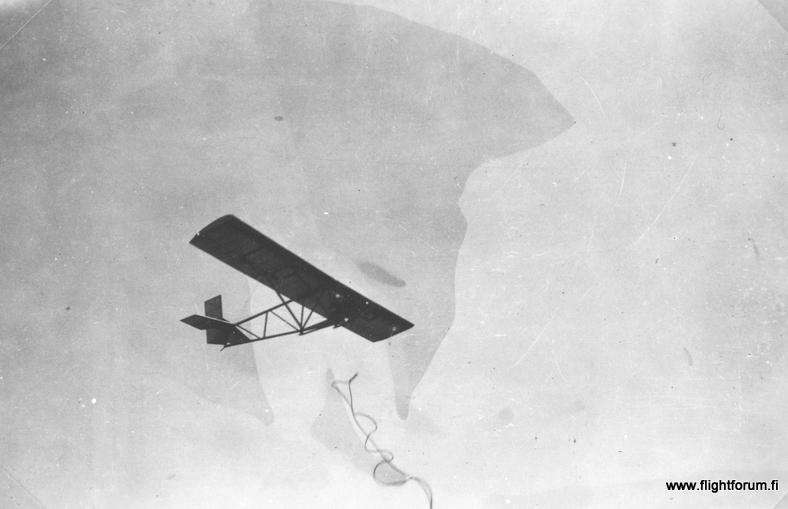

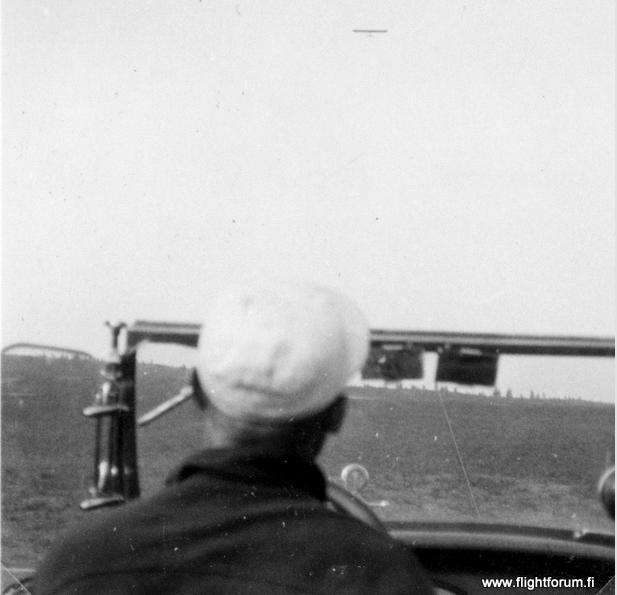

At the start of 1939, Kaario returned to Finland together with his two colleagus and was transferred to the State Aircraft Engine’s new Linnavuori engine plant at Siuro where he was assigned to the aero-engine testing facility. Back in Finland, he now had the time to indulge into what had been a long-time hobby. In 1932, Kaario had come up with the idea of developing a vehicle utilising maavaikutusta (ground effect) and he had actually designed a gound-effect vehicle and built a small working model which worked by generating an air-cushion to support it. Over the winter of 1934-1935 Kaario went on to build the first Pintaliitäjäprototyypin (Pintaliitäjä=Surface Soarer, thus “Prototype Surface Soarer”), which was tested on the ice in January 1935.

Toivo Kaario on an early Pintaliitäjäprototyypin in mid-1935

Based on experience testing the first prototype, Kaario went on to build a second prototype, Patosiipi No. 2 which he tested over 1935-1936. Kaario began to develop his theories concerning the use of ground-effect and built several models for further tests. As the ground-effect wing of Kaario’s early designs had an almost non-existent ability to block the loss of air being blown down by the propellor, the Patosiipi No. 2 was able to lift, but the ground-effect lift was weak. Kaario continued to experiment through 1936, building a further full-sized prototype powered by a 2-cylinder Harley-Davidson motorcycle engine but this time with a ”skirt” underneath which added to the lift by trapping the high pressure air that had been forced. This device was first tested on land and then on the water and was found to be slower but with more lift over an uneven surface. It was at this point that Kaario had discontinued his research and trials as he had graduated and is spare time in Berlin was largely taken up with his studies. However, he did have some free time....

And Kaario used this time well, bouncing his ideas around with German aviation experts, draw new designs, build and test models and come up with further improvements. In the late 1930’s when Kaario was in Germany, German aviation had been released from the shackles imposed after the defeat of WW1, the Luftwaffe was expanding rapidly, German aviation designers were trying out a variety of new ideas and concepts, some of them out there on the bleeding edge of technology, many of them merely leading edge, and Kaario found himself in the thick of this. His interests led him to make many contacts, and on his return to Finland in January 1939, Kaario had accumulated two years worth of ideas, thoughts and interaction with German aviation experts as well as having constructed and trialled a large number of models. Almost all his spare time was taken up with building and testing models and almost immediately he also began work on Patosiipi No. 8 which had substantially improved lift and air flow properties. At this stage a number of fellow workers at the State Aircraft Factory had become interested in his project and provided voluntary assistance. Work on Patosiipi No. 8 progressed rapidly tilizing a 53hp Porsche engine and before the snow was off the ground in the Spring of 1939, the device was first tested on land beside the Härmälä airport and then on the water at Siuro. The main problems experienced were vibration when driving on uneven ground and the inability of the prototype to drive over obstacles more than 20-cm-high. Sometimes serendipity plays its part in events. It was the testing beside Härmälä airport that inadvertantly led to far more rapid progress than Kaario had anticipated. Major-General Somersalo had been attending a meeting at the Airport whic had run late. On leaving, he happened to see the group working on Patosiipi No. 8 and stopped to watch as a test run was carried out, with the device reaching some 80kph while carrying two people. Intrigued, Somersalo had walked over to the group and started asking questions. At midnight, the entire group and Somersalo were still at the Airport with Kaario running an impromptu design review.

Two days later, Kaario and his team of volunteers found themselves doing a presentation to Somersalo, the head of the Merivoimat, Väinö Valve, the comanding officer of the Marine Jaegers, a small group of technical Officers and a couple of rather tough looking individuals in nondescript Maavoimat uniforms without any rank or branch identification. Kaario seized the opportunity and over a single day, he outlined the concepts and ideas he had put together while in Germany, starting with plans for a 100 ton Pintaliitäjä intended for transport on the Baltic Sea and with a cruising speed of 100-120kph, then moving on to concepts for a Fast Torpedo and Minelayer Pintaliitäjä and a High Speed Infantry Assault Pintaliitäjä. The ”ground effect” concept was explained in detail, and then demonstrated using Patosiipi No. 8, and Kaario’s ideas on how this could better be utilised were also explained (Kaario was perhaps the first to conceive of using a ”skirt” to trap air, rather than simply using ground-effect).

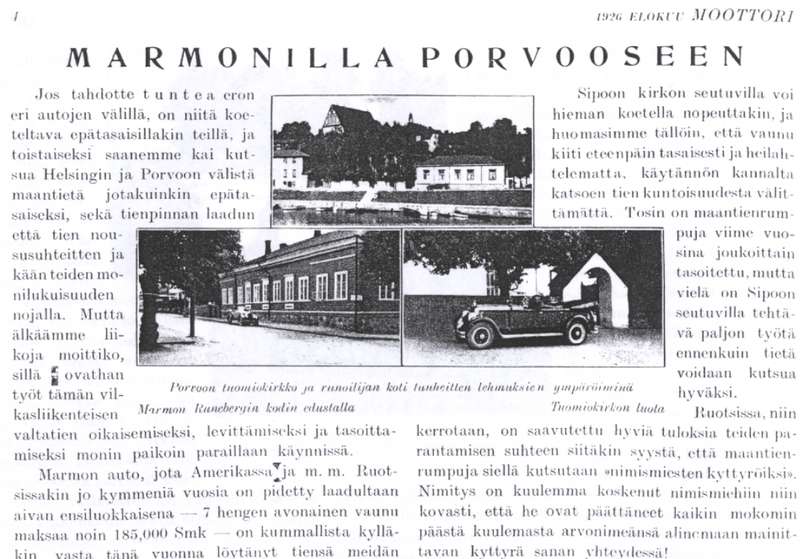

Line Drawing of Pintaliitäjä-Craft proposed by Kaario in Spring 1939

Rough Sketch of Infantry Assault Pintaliitäjä-Craft as proposed by Kaario in Spring 1939

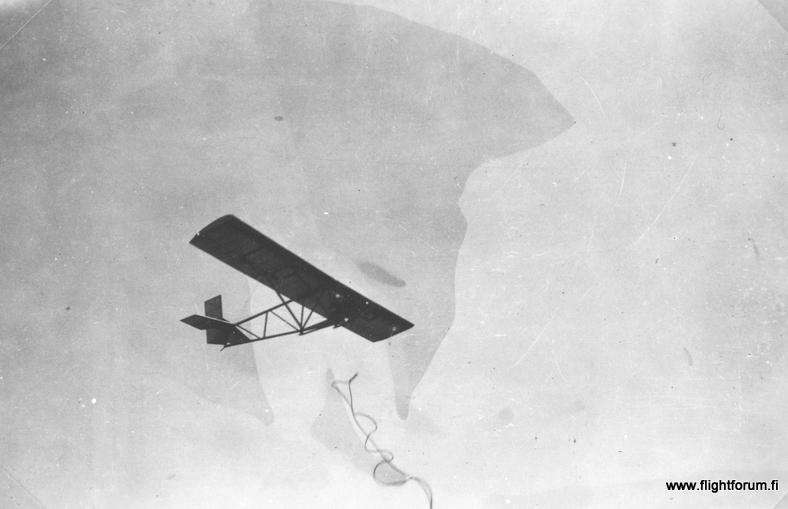

The next morning he was summoned to the office of the Manager to find, not the Manager but the Commanding Officer of the Merivoimat, Väinö Valve. After a short and to the point discussion, Valve asked Kaario if he would take on a position as leader of a design and development team tasked with turning his Pintaliitäjä concept into a viable military weapon within a 12 month period. Adequate resourcing would be provided and the project would have the full backing of the Merivoimat. Kaario agreed. Almost immediately, a team was assembled and design work began for a full-size protoype of the Fast Torpedo and Minelayer Pintaliitäjä. The first prototype, maintaining the numbering sequence Kaario had initiated in 1932 was designated P-9, and had a very simple design which consisted of an elongated oblong shape made up two wooden catamaran hulls and powered by three aircraft engines using what we would now call a chamber configuration design. Two Mercury aero-engines were installed horizontally in the funnel-shaped wells on the platform which connected the catamaran hulls together. The third engine, also a Mercury, was placed in the aft part of the craft on a removable four-strut pylon. An air cushion was produced by the horizontally-placed engines. P-9 was designed and built over a one week period and was immediately trialled, achieving a speed of 70 knots, or about 130 kilometers per hour.

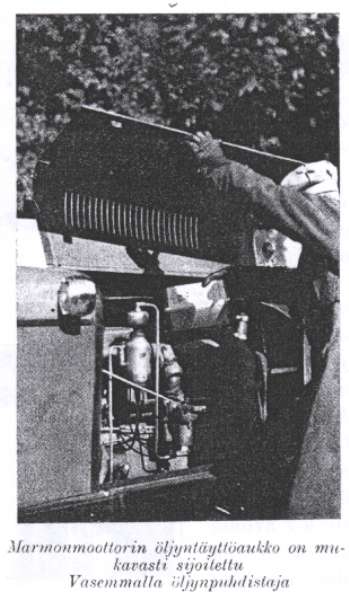

P-9 during initial trials in Spring 1939- the Red Star and ”CCCP” were painted on the sides to confuse any Observers, as it was known that the USSR was conducting trials on a similar type of craft designed by a Soviet engineer, Vladimir Levkov. It was hoped that any sightings of the Finnish craft would be confused with the Soviet Navy craft that had been observed carrying out trials.

The tests lasted for 10 days and at that time nobody other than Kaario and his small team of volunteers had any experience in operating such vehicles. Overwater runs were performed using all three engines running simultaneously, with the trials conducted in both calm and windy weather, crosswind and downwind, over flat shore and over swampy areas covered with sedge. Once the hovercrafts engines failed and the vehicle landed in a deep swamp. However, as soon as the engines were restarted, the boat ascended and recovered itself from the swamp. The maximum speed in the first runs was approximately 60 knots but in later tests 70 knots was easily reached and according to the P-9 test commander, a Merivoimat Fast Torpedo Boat commander, this was not on full power. Trial results of this first prototype hovercraft were acknowledged as very satisfactory. It was indicated in the report that the “principle for surface-soarer vehicles has been proven feasible.” This report was approved by the Commander of the Merivoimat, who directed that the Naval Construction Plan should encompass the production of two types of such skimming boats: one to be used as a fast attack torpedo craft and the other as a marine landing craft. Emergency Funds were allocated and the project was given the highest priority with a direction that three prototypes of each were to be constructed and completed by the end of summer 1939. This was a highly aggressive timetable, but one that the team worked day and night to meet.

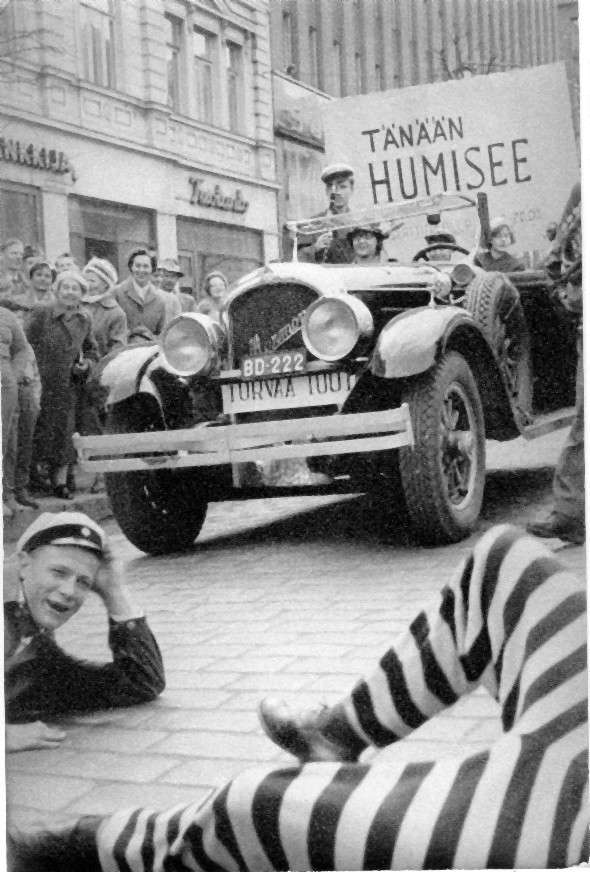

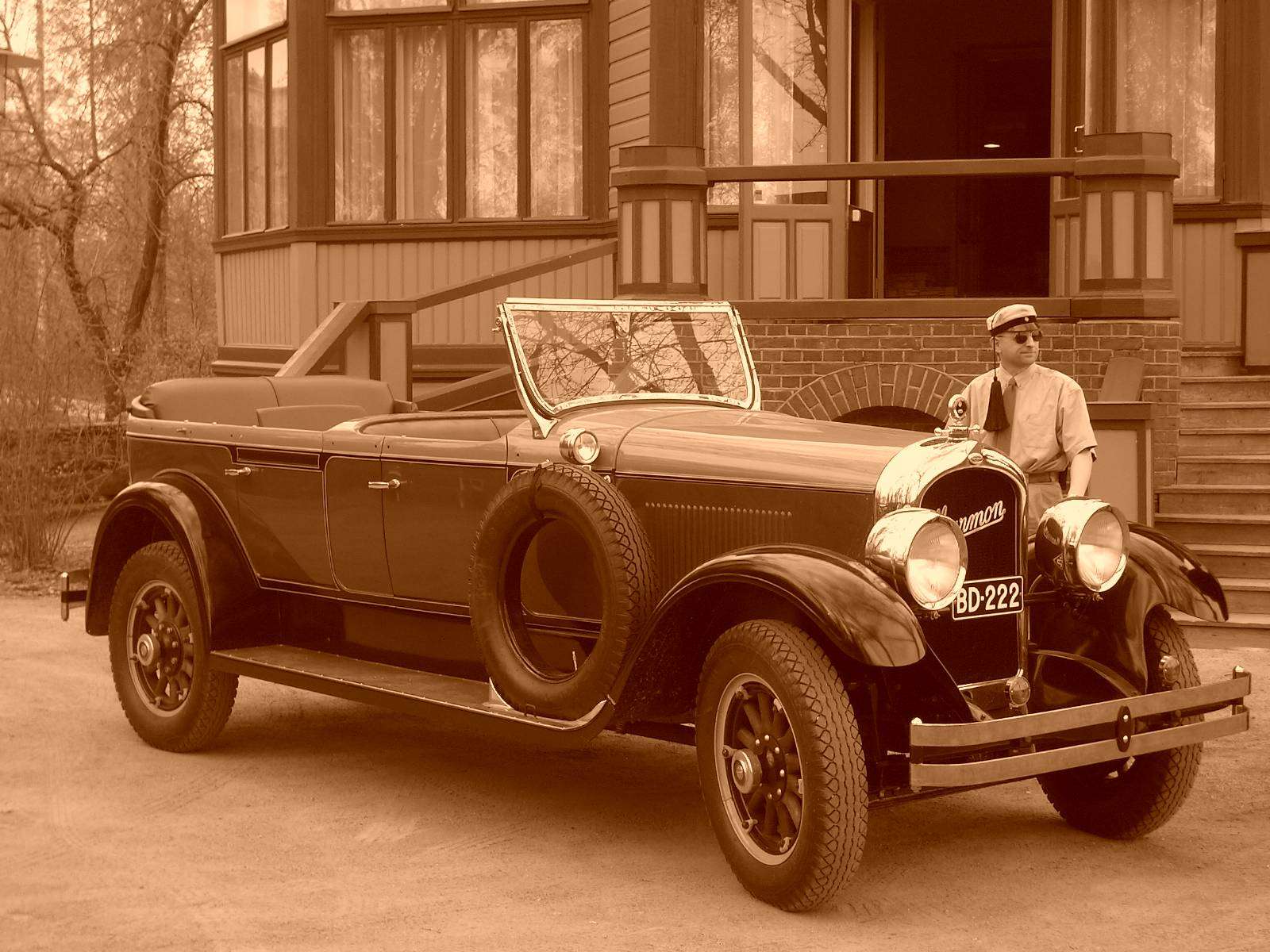

P-10 at rest during a break in her initial trials P-10 had been designed over a four week period and a prototype was put together by mid-July 1939.

Performance Trials of P-10 on the Gulf of Finland, Summer of 1939. ”CCCP” was painted on the sides to confuse any Observers, as it was known that the USSR was conducting trials on a similar type of craft designed by a Soviet engineer, Vladimir Levkov. It was hoped that any sightings of the Finnish craft would be confused with the Soviet Navy craft that had been observed carrying out trials.

Building on knowledge gained from the P-10, a full-metal (duralumin) fast torpedo and infantry assault craft, designated P-11 was built in late summer 1939. The craft had a streamlined shape, in the midship area there was a streamlined pilot house/cabin for the pilot, mechanic and radio operator followed by a troop compartment, two turret (aircraft turrets were used, as had been done with some of the patrol torpedo boats) machine-gun mounts were installed on either side and slightly aft of the pilot-house and there was an aft mounted rear-facing 20mm cannon for AA protection. Directional control was provided by two large tail fins. Torpedo attachment points were arranged on either side of the troop compartment and the craft could also carry eight depth charges. The P-11 could surmount sandy strips, bogs, ice and rough seas, but was unstable during high speed turns. Regardless, a decision was made that it should go into production and by November 1939, the Merivoimat had 21 experimental air-cushion dual-purpose P-11 Pintaliitäjä-boats (High-Speed Torpedo Boats and Assault Craft) in service. The P-11 had a tonnage of 8.6-11.3 t, a crew of 7 men, a length of 24m, a width of 5.4 m, was armed with 2x12.7mm machineguns and 1x20mm Hispano-Suiza 20mm Cannon, carried two torpedoes, was powered by 2x1000hp Hispano-Suiza engines and could reach a top speed of 80 knots (approx 160kph).

As the Winter War broke out, Kaario’s team worked on manufacturing additional P-11 Pintaliitäjä-boats and repairing these that had been damaged while Kaario next began to work on an improved P-11 design as well and then, as this changed radically, it became the design for a larger and longer-ranged P-12 Pintaliitäjä-boat. With more P-11’s having been built and actually being used in operations during the early weeks of the Winter War, Kaario realised the craft had some serious shortcomings. Both good and discouraging reports were coming from the Merivoimat. The discouraging reports stated that pressure under the Pintaliitäjä-boats was low due to air escape through the vessels open ends, which reduced the load-carrying capacity; spray produced by the powerful engines limited visibility, the Pintaliitäjä-boats operations were limited to sea state 4 or less amd the impact of the Pintaliitäjä-boats with waves changed the settings of the louvres and occasionally damaged them. The engines also had problems with stalling when water penetrated into the exposed carburetors, and since the engines were positioned horizontally, they were not sufficiently air-cooled and would often overheat if run for long periods of time. Despite this, the Pintaliitäjä-boats had proved highly effective in combat due larely to their unbelievably high speeds.

Kaario and his design team worked 16 hour days working to rectify these problems, often sleeping under their desks in the ex-VL Suomenlinna factory building that was now their base. In the end, the ability of the P-11 design to cope with high speed turns seemed to improve with a substantial widening of the boat, first to 10m and then to 15m. As for lift, Kaario initially experimented with the building of a working model that demonstrated that by pumping air into a narrow tunnel around the perimeter of the underneath of the craft, it would flow towarda the center, creating a more effective air cushion. This peripheral jet would allow the air pressure to build enough to equal the weight of the craft and, since the air would be trapped, the pressure would elevate the craft off the surface upon which it traveled. By contrast, the P-11 utilised ground-effect, basically provided lift by using a propellor fan to force air from the deck down into the chamber between the two catamaran sides, which meant that air had to be continually pumped down to replace the air that escaped. After successfully trialling a model demonstrating that his new “air cushion” theory worked, Kaario redesigned P-12 incorporating a number of other modifications, a subject we shall return to after the Winter War.

OTL Note: Historically, Toivo Juhani Kaario was a Finnish engineer and inventor, who in the 1930s started working on prototypes of air cushion vehicles. Kaario is considered to have designed and built the first functional ground effect vehicles, but his invention did not receive sufficient funds for further development. Also, in this ATL I have shifted the dates by a couple of years to fit the scenario. But all else aside, Kaario WAS the first in the world to design and build functional ground effect vehicles and the Soviet engineer, Vladimir Levkov, followed his efforts as closely as was possible before building his pre-WW2 combat hovercraft for the USSR…… Toivo Kaario died at the age of 58 after a short illness in October 1970. He is buried at Tampere in the Kalevankangas Cemetery.

A little more on Valtion Lentokonetehdas through the 1930's

A little more on Valtion Lentokonetehdas through the 1930’s

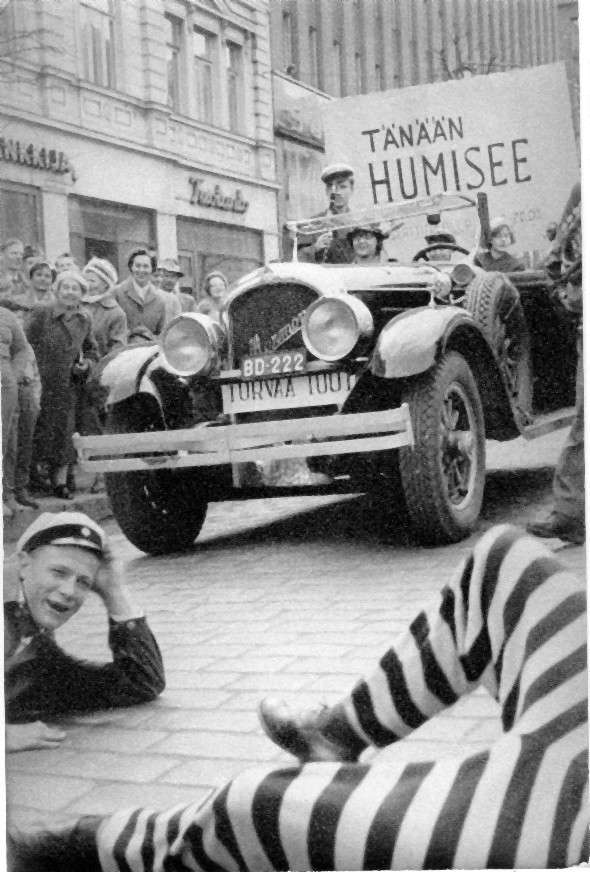

As we have seen, Valtion Lentokonetehdas was established outside Tampere over 1935-1936, with the State Aircraft Factory being established nearby over the same period and producing Bristol Mercury and Rolls Royce Merlin engines in small numbers. The second aircraft-engine facility set up in Finland was the Tampella-Hispano-Suiza Aircraft Engine Company, established in 1936 to manufacture the Hispano-Suiza 12Y Aircraft Engine and with the plant beginning production in 1937. We have also covered the establishment of the Hispano-Suiza cannon factory in the late thirties (as we will see in a later post, this factory was one of a number involved in the production of weapons and munitions in the Tampere area). In addition, Veljekset Karhumäki (the "Karhumäki Brothers"), with their location at Härmälä Airport were also involved in small scale aircraft construction and, after the signing of contracts and receiving of grants for the construction of facilities from the government, involved in the assembly of imported aircraft and the maintenance and repair of all Ilmavoimat aircraft.

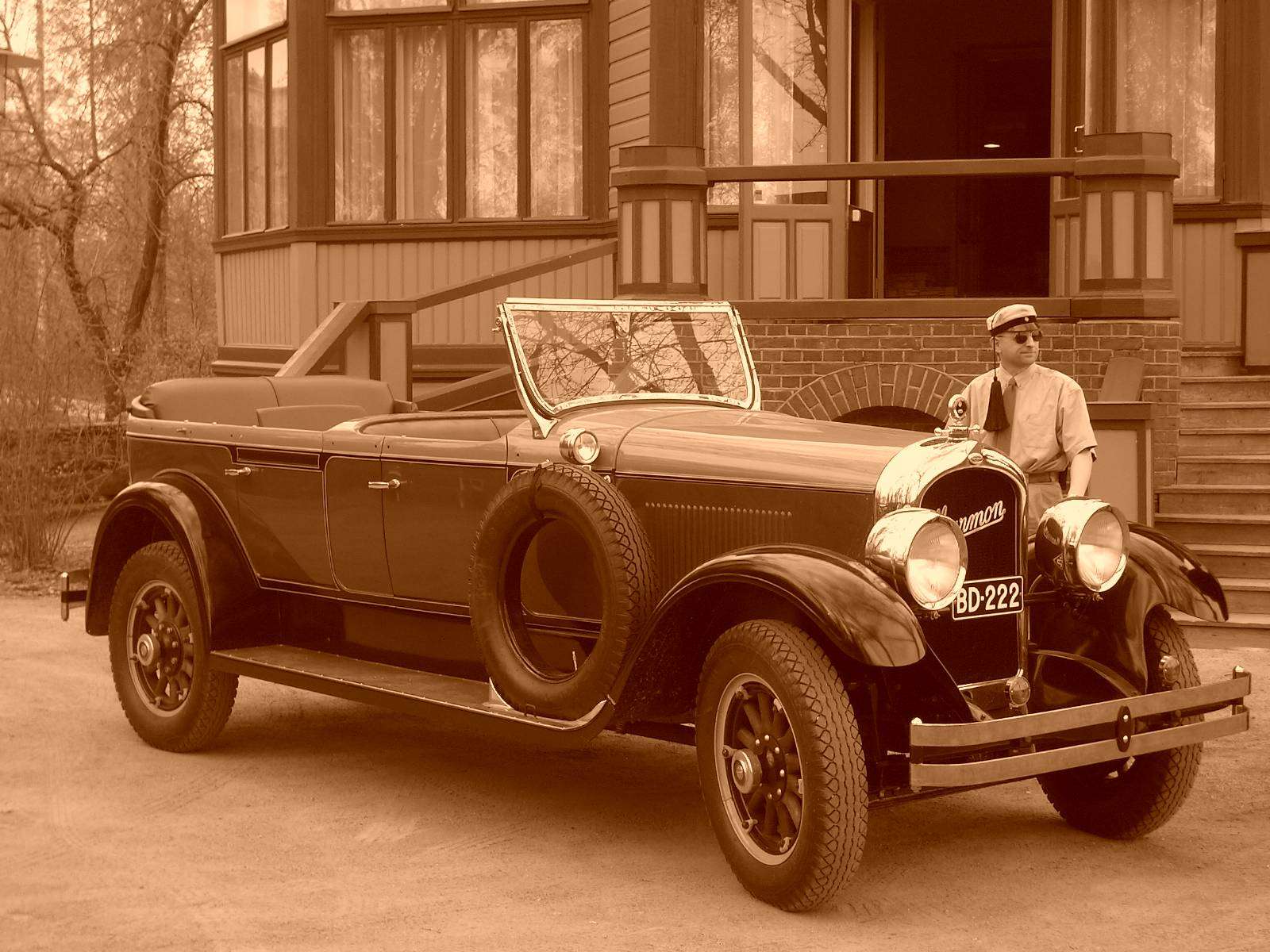

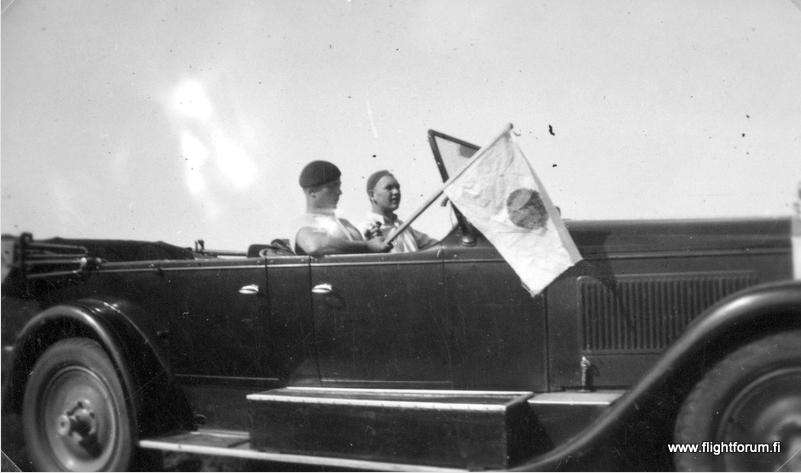

All of this expansion meant that the aircraft industry and its offshoots were a major employer in the area, with the new industrial area of Halli largely created by these factories. The location of these around the area of Härmälä Airport also resulted in the Ilmavoimat Flight Depot and Test Flight Section to the region, as well as the establishment of an Ilmavoimat base at the airfield. Test flying was important in peace time, because flight training caused a lot of damage to the aircraft and that in turn meant repair work for the industry. Information about new Ilmavoimat planes was also gathered through test flights, as while there were manuals available, they often did n ot reflect the true capabilities and limitations of the aircraft. And with Veljekset Karhumäki already operating civilian flight training and building small aircraft for private use, Härmälä Airport was busy from the start. In the Spring of 1937, Marshal Mannerheim had made a surprise visit to the Veljekset Karhumäki airplane workshop in Keljo. Later that same year, the engineers Koskiala and Kuusinen suggested that the company should expand and relocate from Keljo to a more suitable site. In late 1937, after the signing of the contract for aircraft assembly and maintenance and the recieving of the government grant for construction of larger and improved facilities, the Veljekset Karhumäki airplane workshop in Keljo was relocated to Kuorevesi and became increasingly busy, employing some 750 workers by mid-1938.

Over the period we are looking at in this post, from 1931 to late 1938, Valtion Lentokonetehdas went on to build a number of aircraft under license as well as continuing work by its own aircraft design department as well. Several Finnish designed aircraft types were produced by the factory between 1930 and the end of WW2, although in this post we will only cover the period to late 1938. Several designs for aircraft were developed, with prototypes flying and in the 1930s, generally achieving comparable performance with foreign types. While the primary aircraft types were usually bought abroad, since buying these was often cheaper than building an entire new aircraft in Finland, Valtion Lentokonetehdas did build some of its own designed for the Ilmavoimat. And course there was fairly large scale (for Finland) construction of aircraft such as the license built Fokker D.XXIs and Blenheims. The Fokker D.XXI however was so thoroughly redesigned in Finland, that the locally built Fokkers ended up being more Finnish-designed than Dutch. From late 1937, a clear division of responsibilities with Veljekset Karhumäki had been established and each Company had a clear set of priorities. This carried through into the Winter War itself, with Walden as both Defence Minister and Chairman of the Board of VL immediately resolving any disagreements to his own satisfaction, if not to the satisfaction of the Managers of the respective enterprises.