Boldly Going Part 33

Despite the success of

Spirit in the captive carry and glide tests, ground testing of the Shuttle-II’s systems could only go so far. Many of the critical capabilities of the orbiter could only be tested inflight, during ascent or orbital operations. The first Shuttle-II orbital flights would themselves be demonstrators, each adding incremental capabilities from orbit to landing to operations with

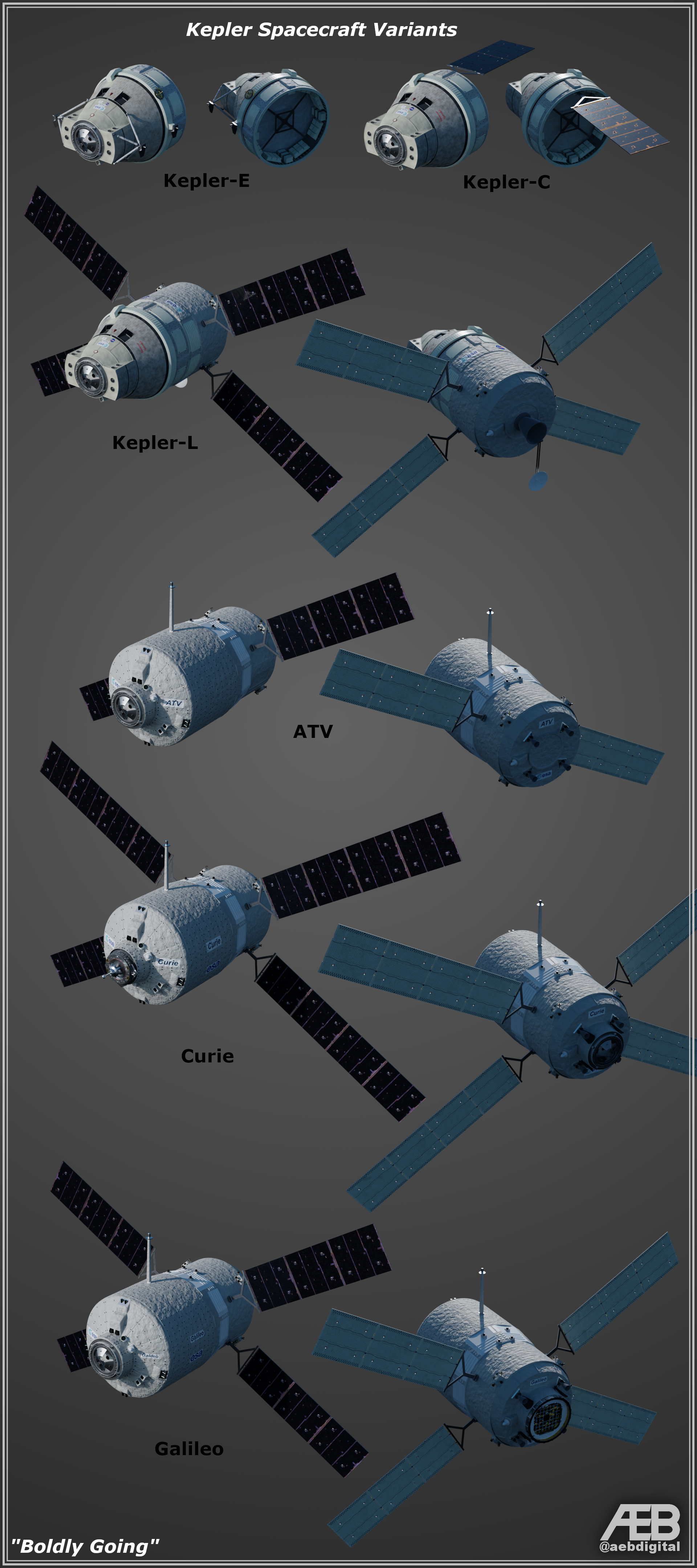

Enterprise. Unlike the original Shuttle, which had flown crewed on its first orbital flight and Shuttle-C, which had flown with crew on merely its second flight, Shuttle-II could perform the majority of its major roles with no crew aboard. Thus, NASA planned a series of five missions to prove the vehicle safe by transporting logistical supplies like MPLMs and

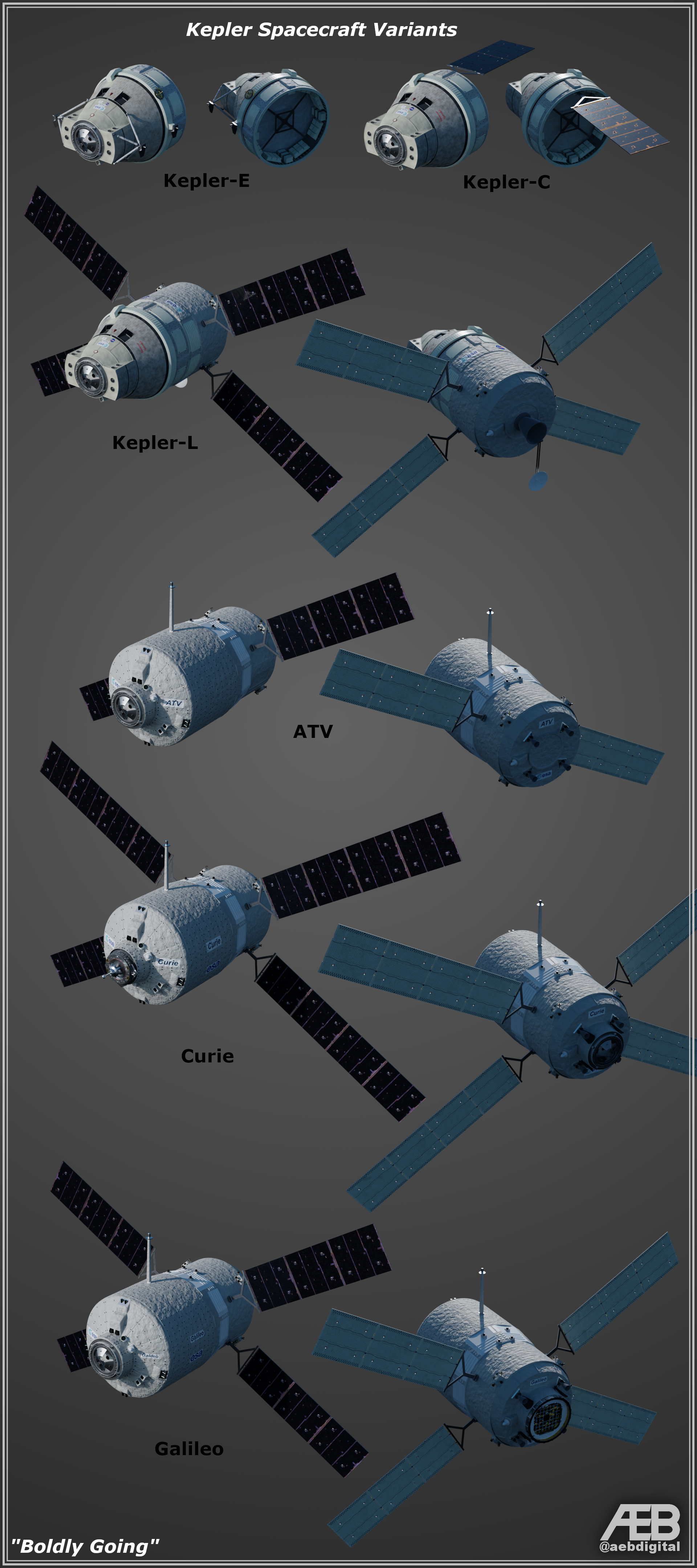

Kepler lifeboats before any lives would be risked.

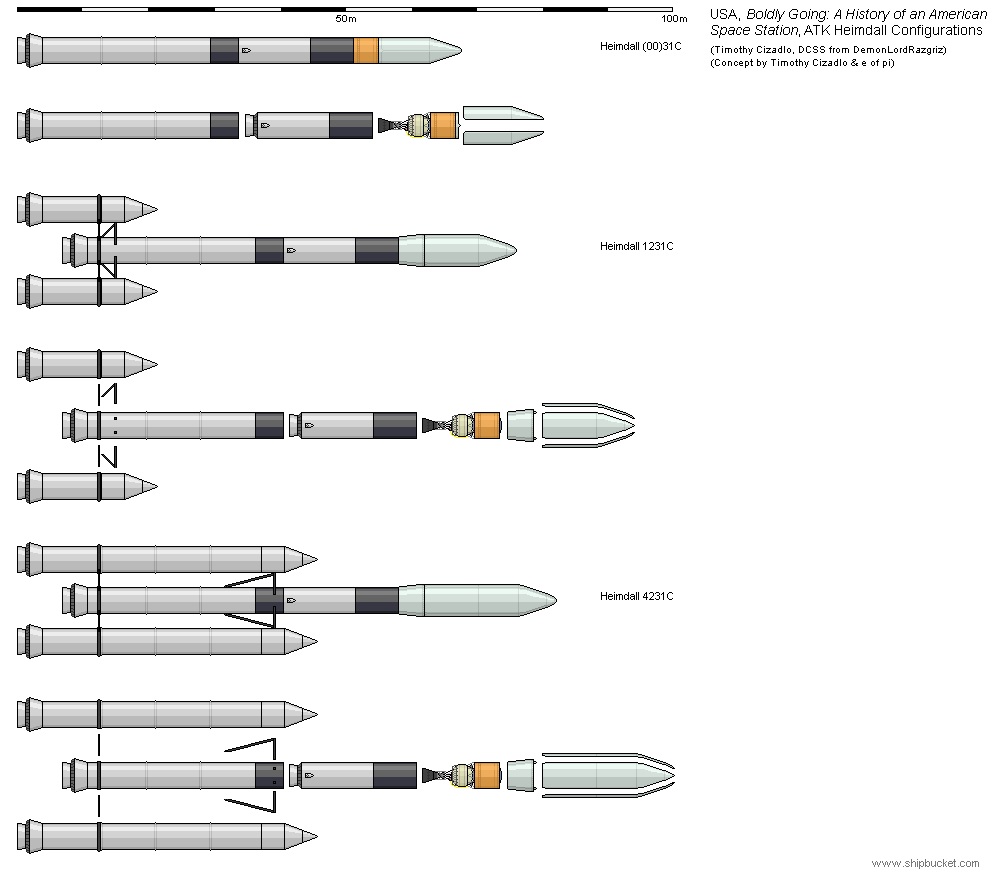

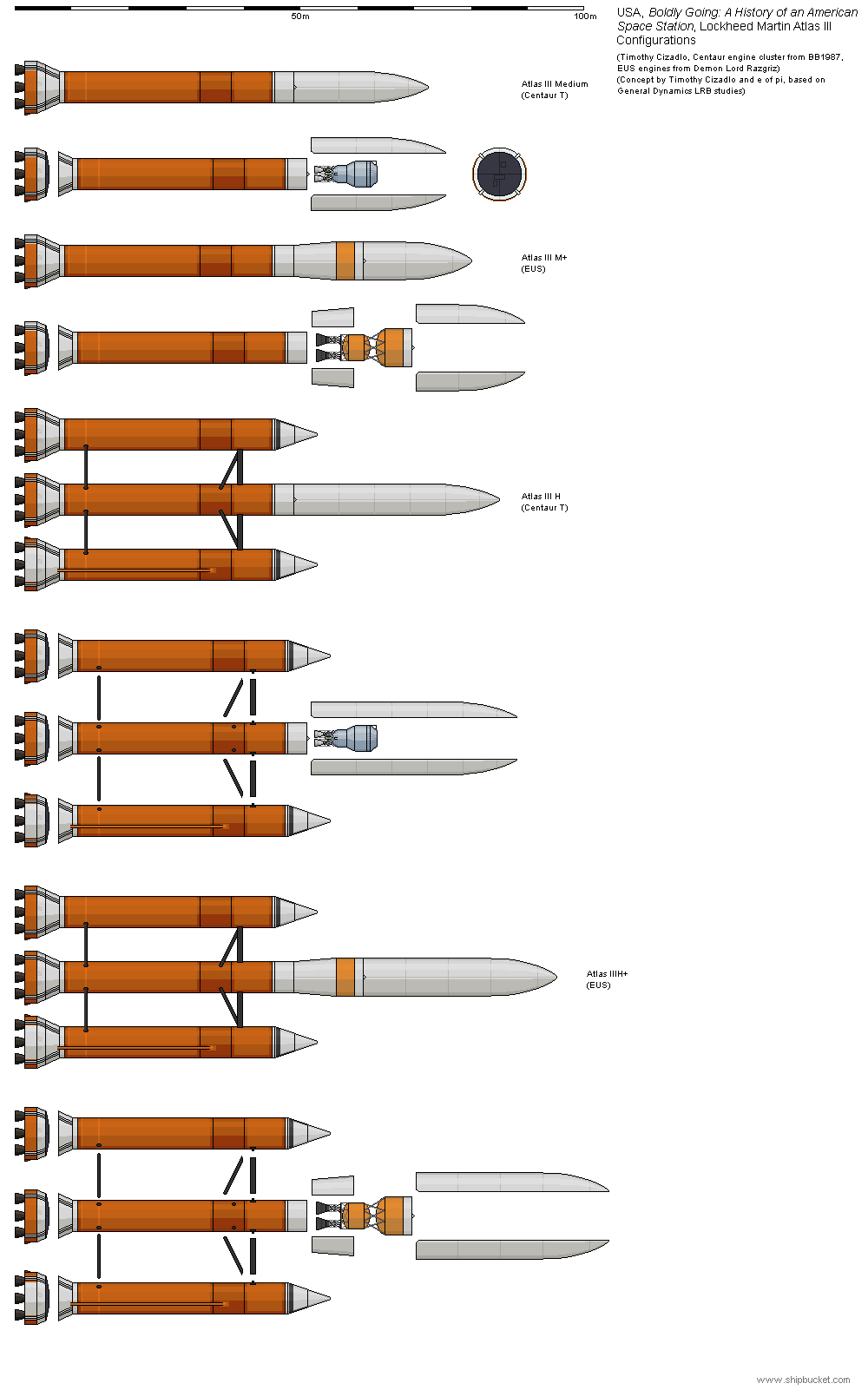

Much like with the introduction of Shuttle-C in the late-90s, NASA allocated a block of consecutive mission numbers to the sequence of demonstration flights, reserving them for use even as the primary Shuttle and Shuttle-C manifest varied from year to year. Shuttle-C’s test flight designation block, including the missions supporting Minerva 2’s return to the moon, was assigned bracketing the coveted STS-100 milestone. Given the prodigious flight rate of the late 1990s and early 2000s and orbital support since, the Space Transportation System was already assigning mission numbers around STS-270 by the time Shuttle-II’s debut mission numbers were reserved. With an eye on public relations, the equally coveted STS-275 through STS-280 were reserved for Shuttle-II’s demonstration flights [1].

Spirit’s captive carry and glide flights and

Independence’s propulsion testing at Stennis were the most visible aspects of the preparations for Shuttle-II’s debut on STS-275. However, before STS-275 could fly, the Cape required extensive logistical efforts to prepare to process the new vehicle and the two existing STS vehicles in parallel. With the transition from SRBs to LRBs, processing flows for normal Space Shuttle operations and even the dual-launch Minerva lunar cargo flights were significantly smoother than they had been during the turn-of-the-millenium peak. Even though the number of launches remained relatively similar, the elimination of nearly 20 days of SRB stacking time (and resulting exclusion of work in adjacent High Bays) meant High Bay 3 was now surplus to requirements for regular stacking. Though it needed to be retained for a “safe-haven” in the event of extreme weather, the processing platforms in the high bay could be dismantled. The platforms were then reconfigured to support stacking Shuttle-II’s twin-LRB first stage, mating Shuttle-II itself, and checking out the assembled combination for flight. Mobile Launch Platform 3, originally built for Saturn V, would now be modified to support another vehicle. The base of the platform had only minor changes as the LRBs for Shuttle-II would retain their distance and positioning relative to each other as on the original Shuttle, and Shuttle-C stacks. The air-started nature of the Shuttle-II main engine also meant that there was no need for a new flame trench for the new vehicle. With just minor modification of the existing service masts and new connections from the LC-39 fixed service structures, all four MLPs could eventually be used with the original orbiters, the well established OPAMs, or the new Shuttle-IIs. LC-39B was the first of the pads to receive modifications to the Fixed and Rotating Service Structures to support the revised vehicle interfaces. In March 2019, the new facilities were activated, and the stacking of

Indepence for her first flight began.

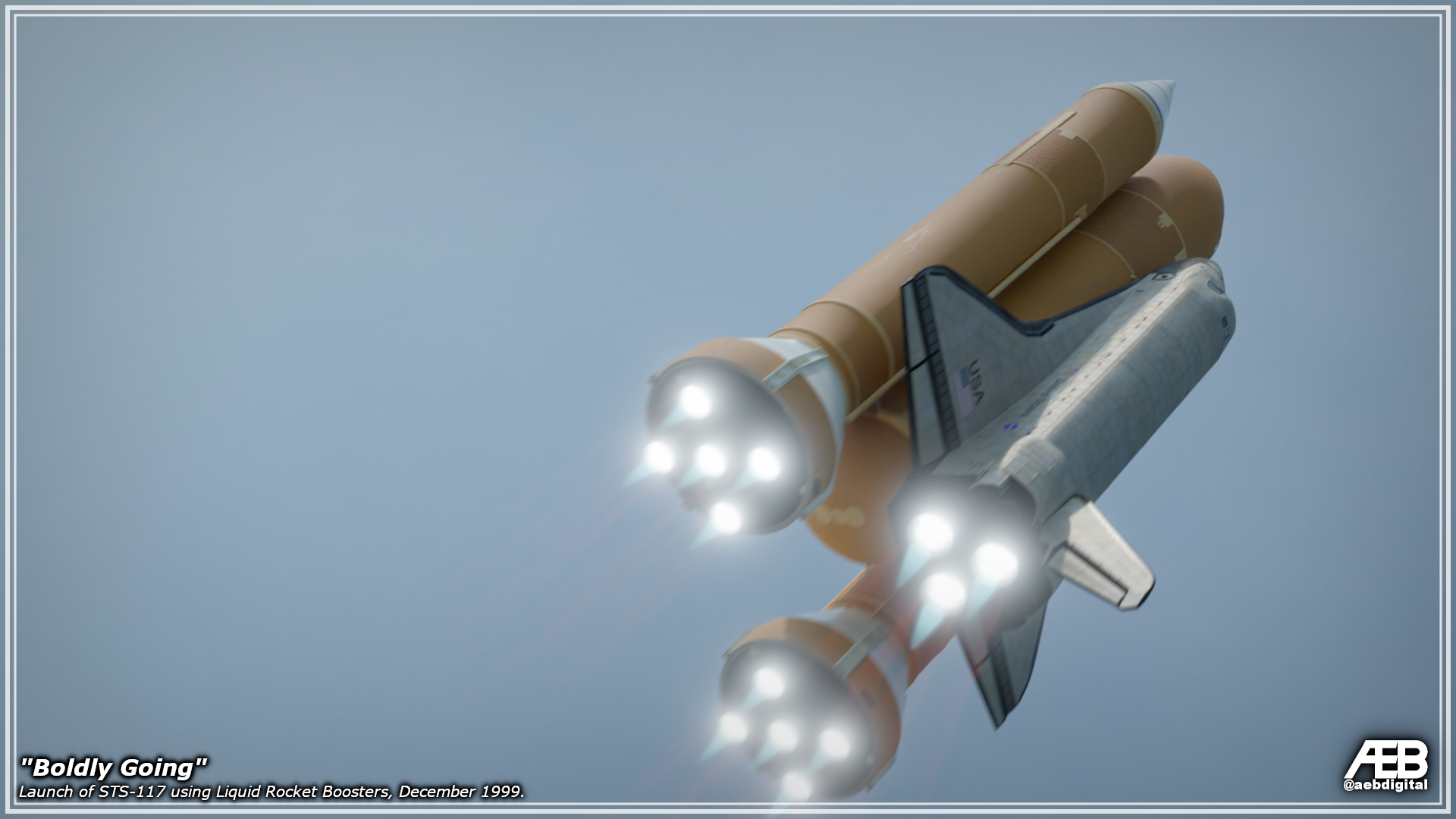

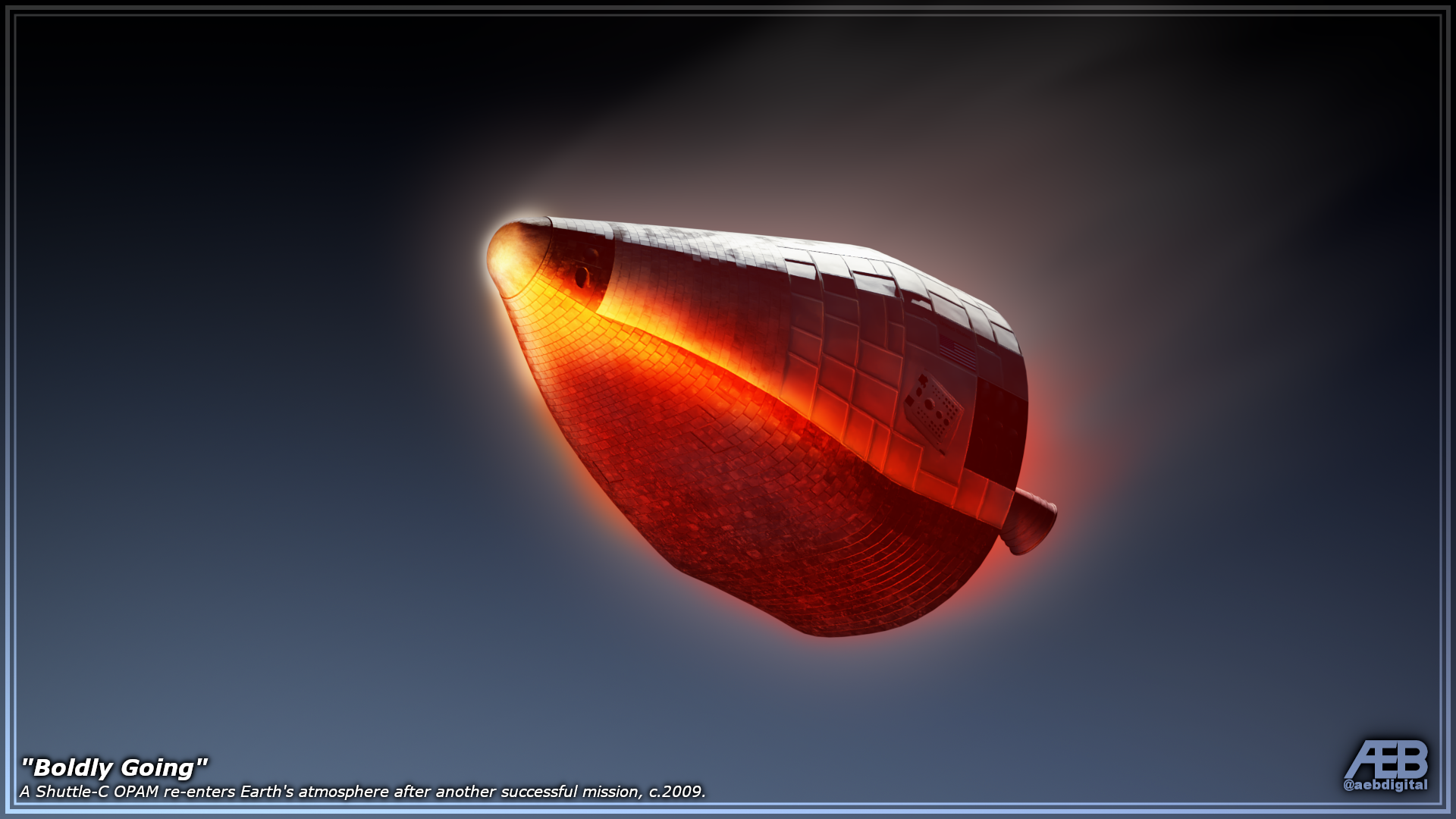

In May 2019, STS-275 made the Shuttle-II’s first trip to the pad. The stack’s appearance was starkly different than any which had come down the crawlerway before. The twin boosters and orbiter hanging between them made for a profile unlike the slightly off-balance Shuttle and Shuttle-C. Though similar to the previous generation orbiter in overall dimensions, Shuttle-II was lighter and sleeker, tucked between its two powerful LRBs. With a lower dry mass thanks to tank-reinforced primary structures, Shuttle-II could make due with smaller wings, which were mounted slightly forward of the fully-aft position on the original shuttle. The nose was a smooth ogive, its analytically calculated aerodynamics unbroken by the need for crew windows. The climb off the pad on the nearly-invisible blue flames of an all-hydrogen stack was picture perfect. Captured by numerous photographers, it looked like something out of science fiction.

The break from routine helped draw attention to NASA’s launch operations. With extensive promotion during preparations for launch, audiences in person and online were nearly 30% larger than the typical Space Shuttle mission. For the next three days,

Independence stretched her wings on orbit, demonstrating basic systems function and vehicle integrity, while onboard cameras recorded the results. However, after launch, the audience for mission updates rapidly shrank. A robotic space plane with no crew might be safer, but general public interest was ephemeral without crew aboard. Though NASA proudly promoted

Independence as the first full-sized cargo spaceplane to land itself uncrewed since the sole Buran landing in 1988, the audience for landing was actually slightly smaller than that of a typical Shuttle return.

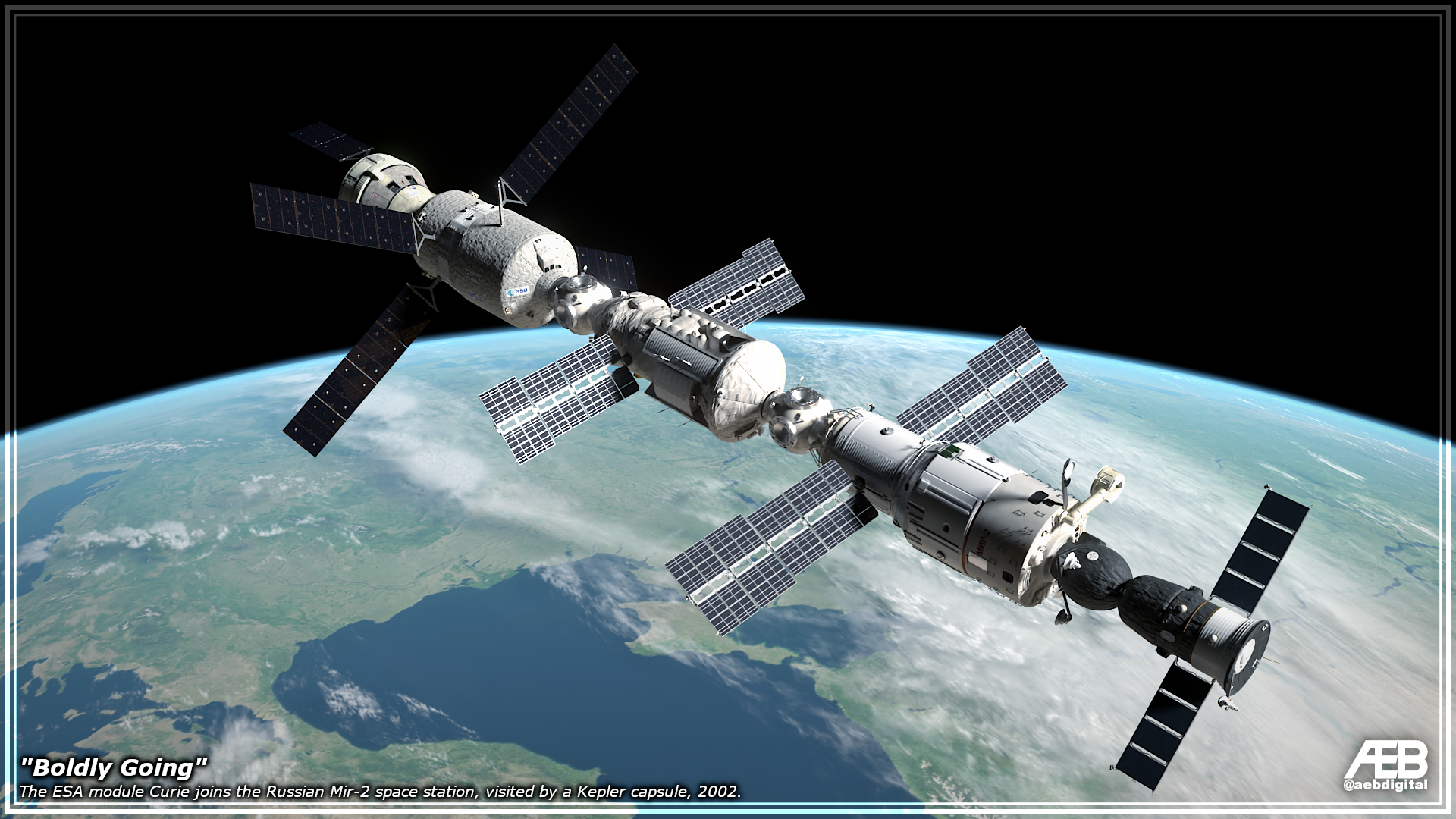

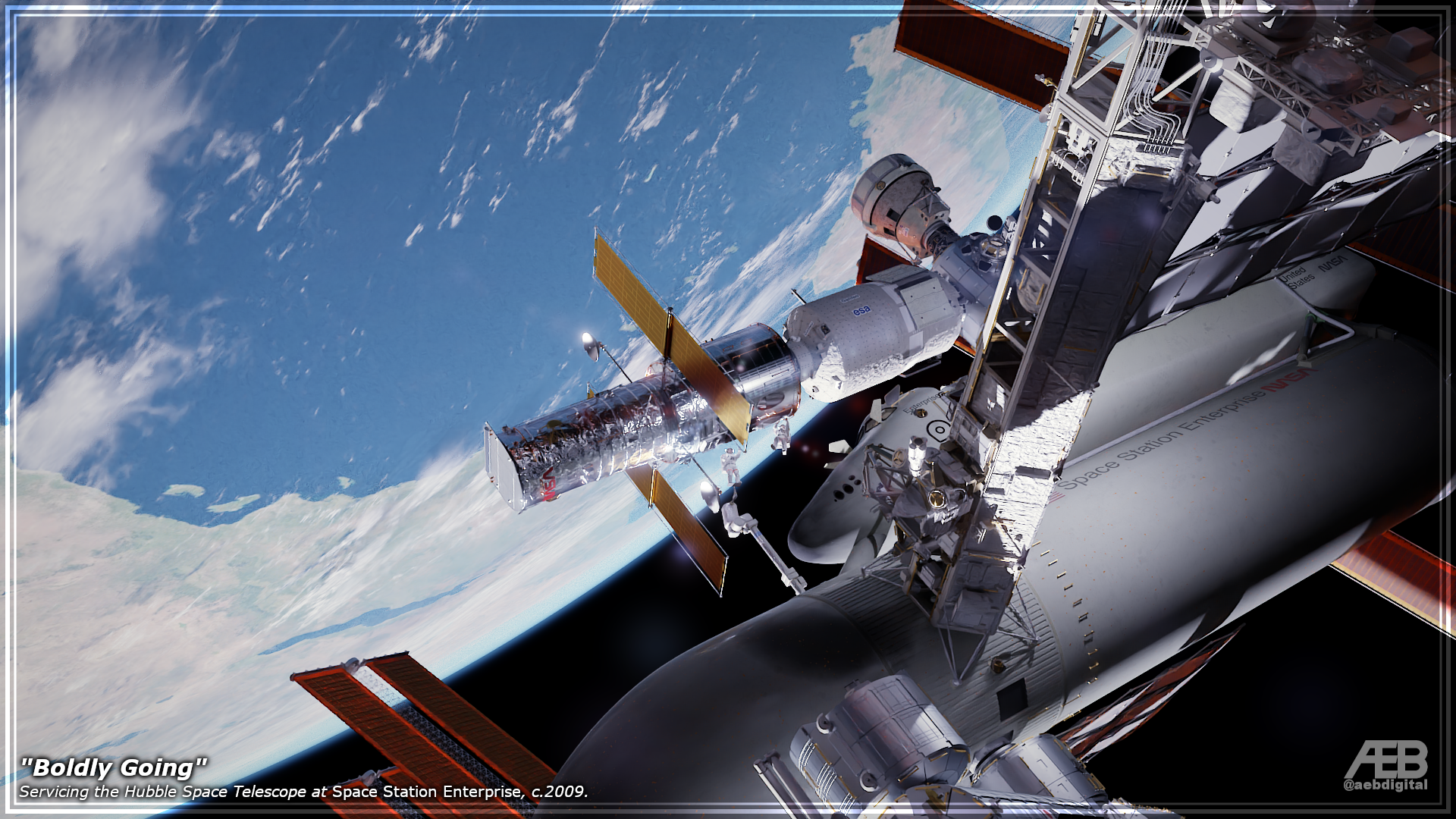

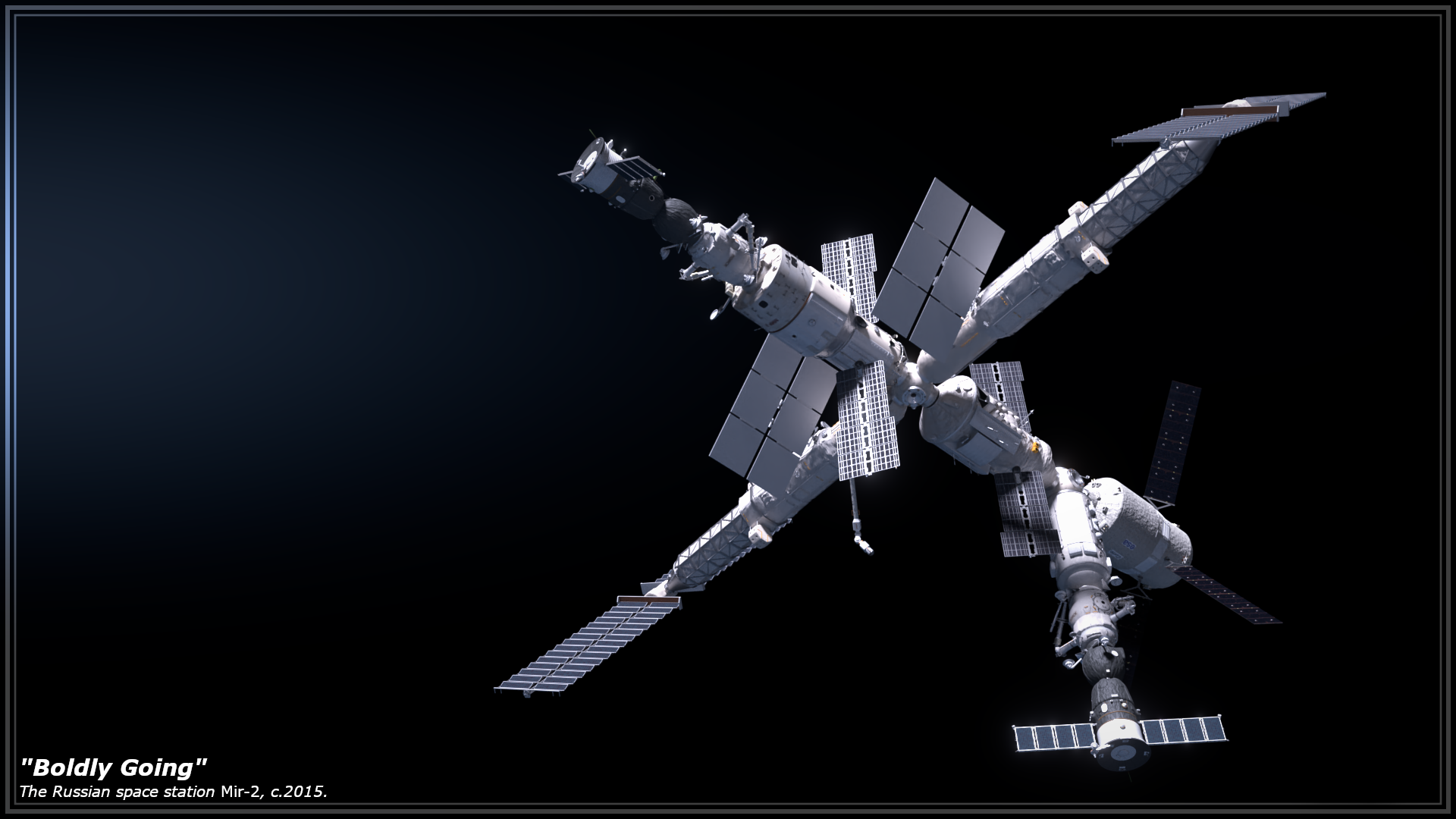

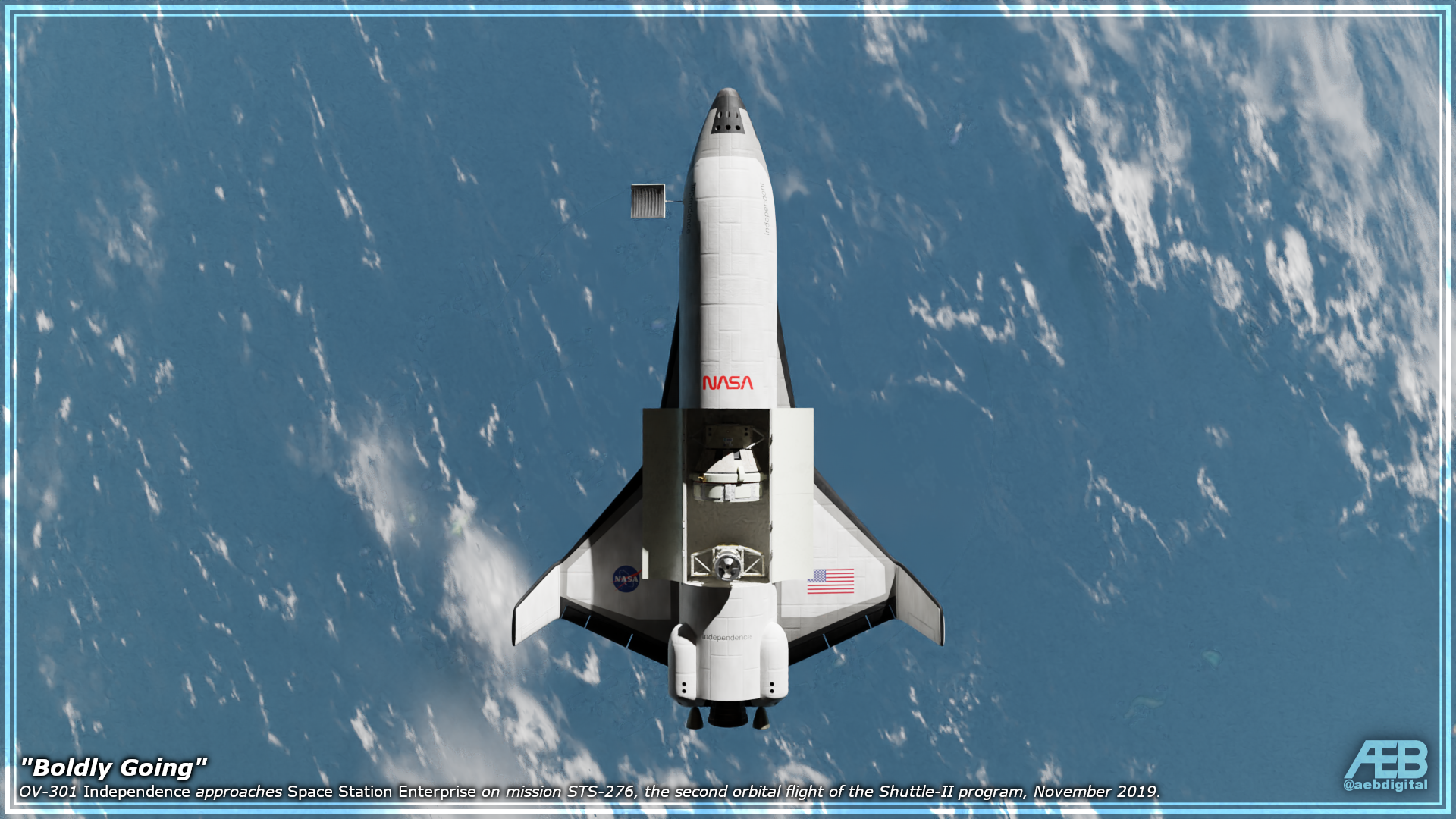

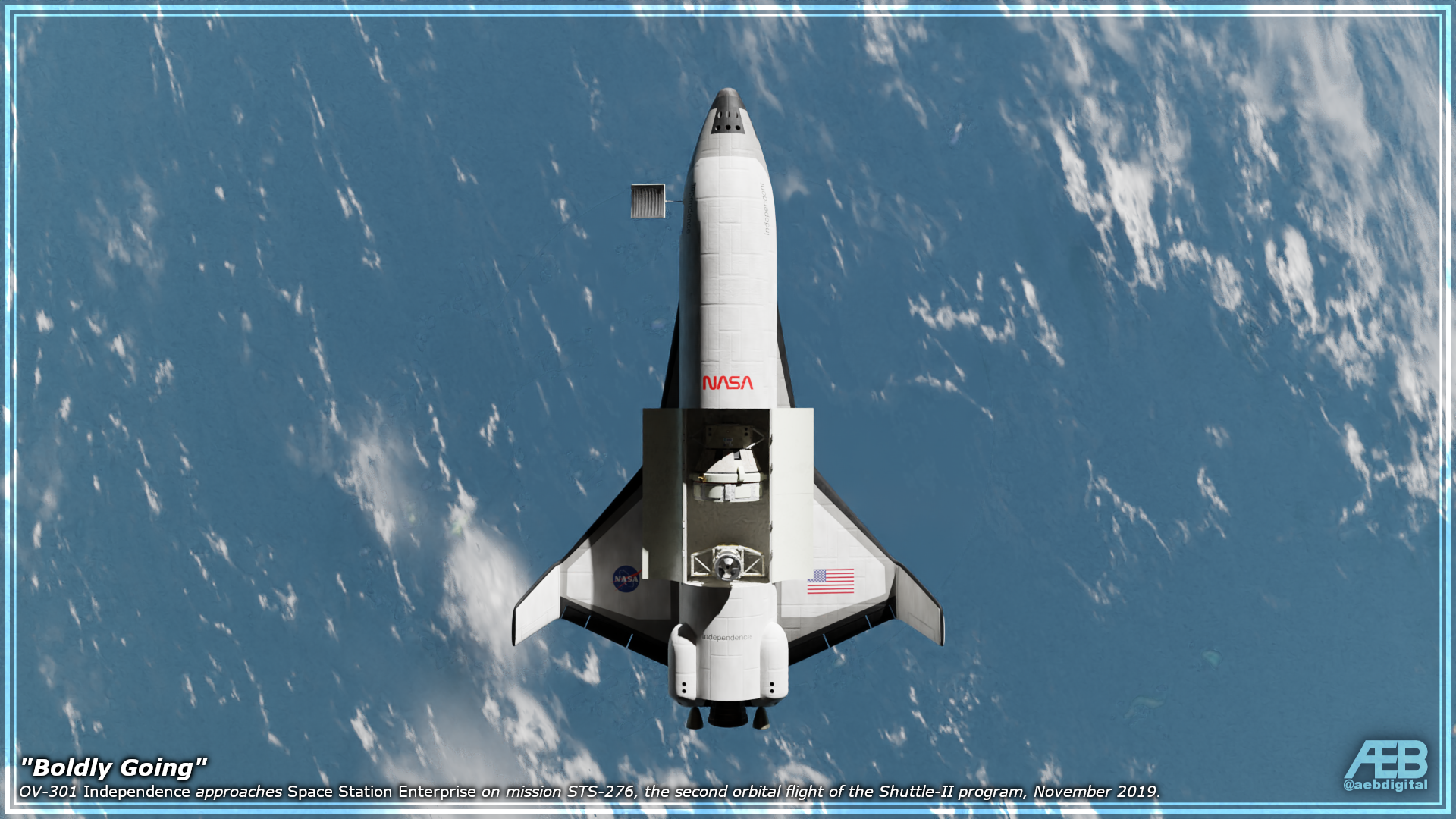

Independence returned for the program’s second flight, STS-276, in November of 2019. This time, Shuttle-II would go to

Space Station Enterprise, like the two conventional Shuttle missions (STS-289 and STS-287) which had launched in the meantime. With the orbiter headed to the station, the viewing audience and news coverage held steadier after launch. During tests in years past, the mini-station

Galileo and the related

Automated Transfer Vehicles had flown with versions of the Shuttle-II avionics in the loop, providing parallel control tests for the new vehicle’s Shuttle-heritage docking radar under automatic control. Still, STS-276 was the first time the massive bird itself had made the trip to NASA’s most storied outpost. The gawky delta-winged orbiter was more awkward to maneuver than the simpler cylindrical

Galileo, and elaborate tests were carried out to prove it was under control during the approach.

Independence

Independence made multiple approaches to the station, pausing several times in each to check that guidance remained on target. The pauses also allowed time to ensure that the massive drone spaceplane responded to abort commands from a control panel in

Enterprise’s operations center, where much of the crew had gathered to oversee events. The hold points moved steadily closer, with

Independence flying formation with

Enterprise first at two kilometers, then at two hundred meters, and finally at twenty meters. For the crew aboard

Enterprise, the giant new orbiter felt almost close enough to touch. Finally, after hours of testing,

Independence’s docking ring slid home at the axial port on the bottom of Node 1.

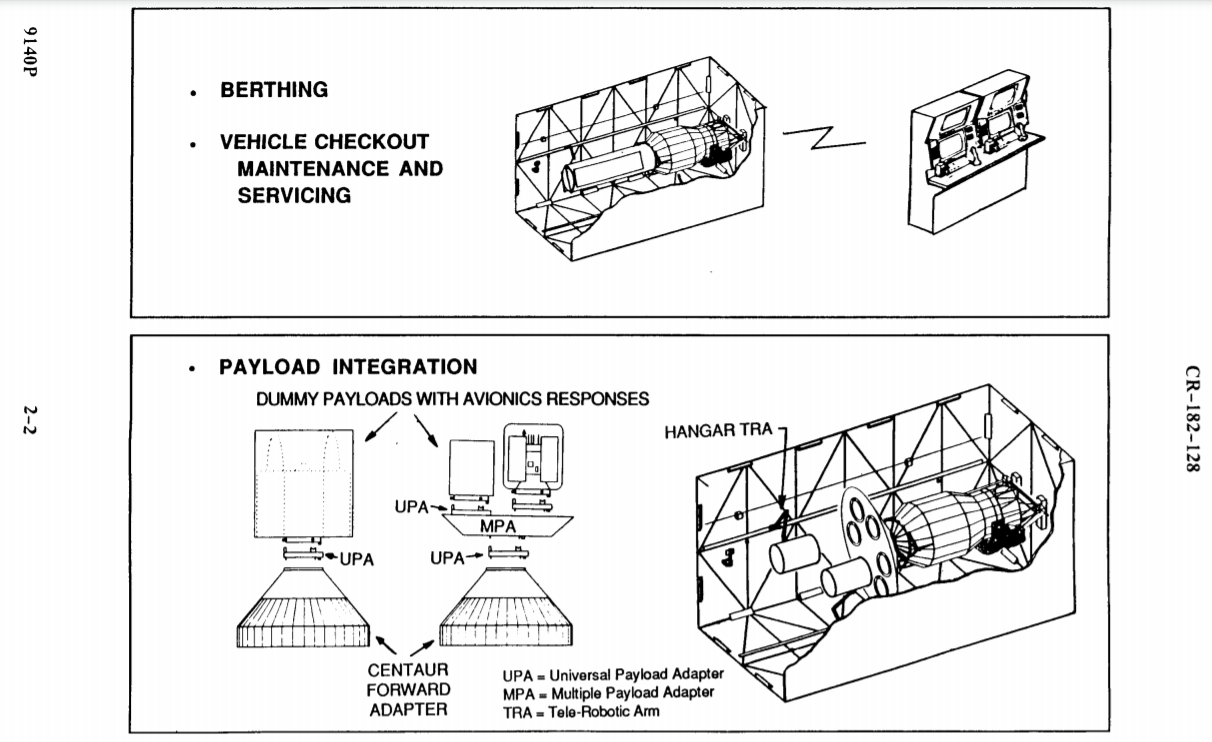

Shuttle-II had proved it could

reach the station, now it remained to be proved that it could

service it, a task which fell in 2020 to the next pair of flights. The cargo bay of the new Shuttle-II orbiters was smaller than their predecessors, and made smaller still by the cramped docking module all uncrewed missions to

Enterprise would have to carry. Still, the remaining space would be large enough for either of the two most critical payloads: the ESA

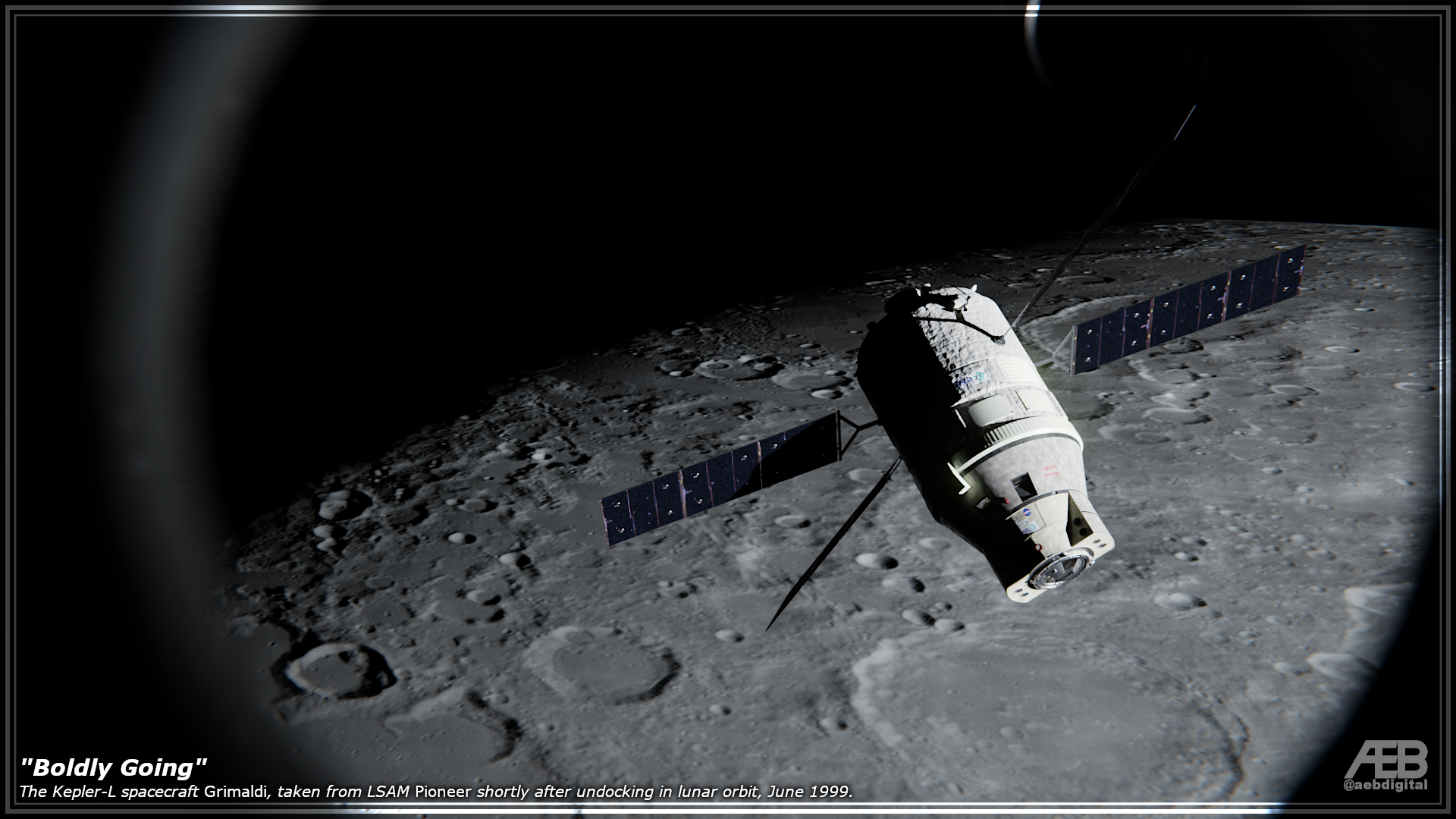

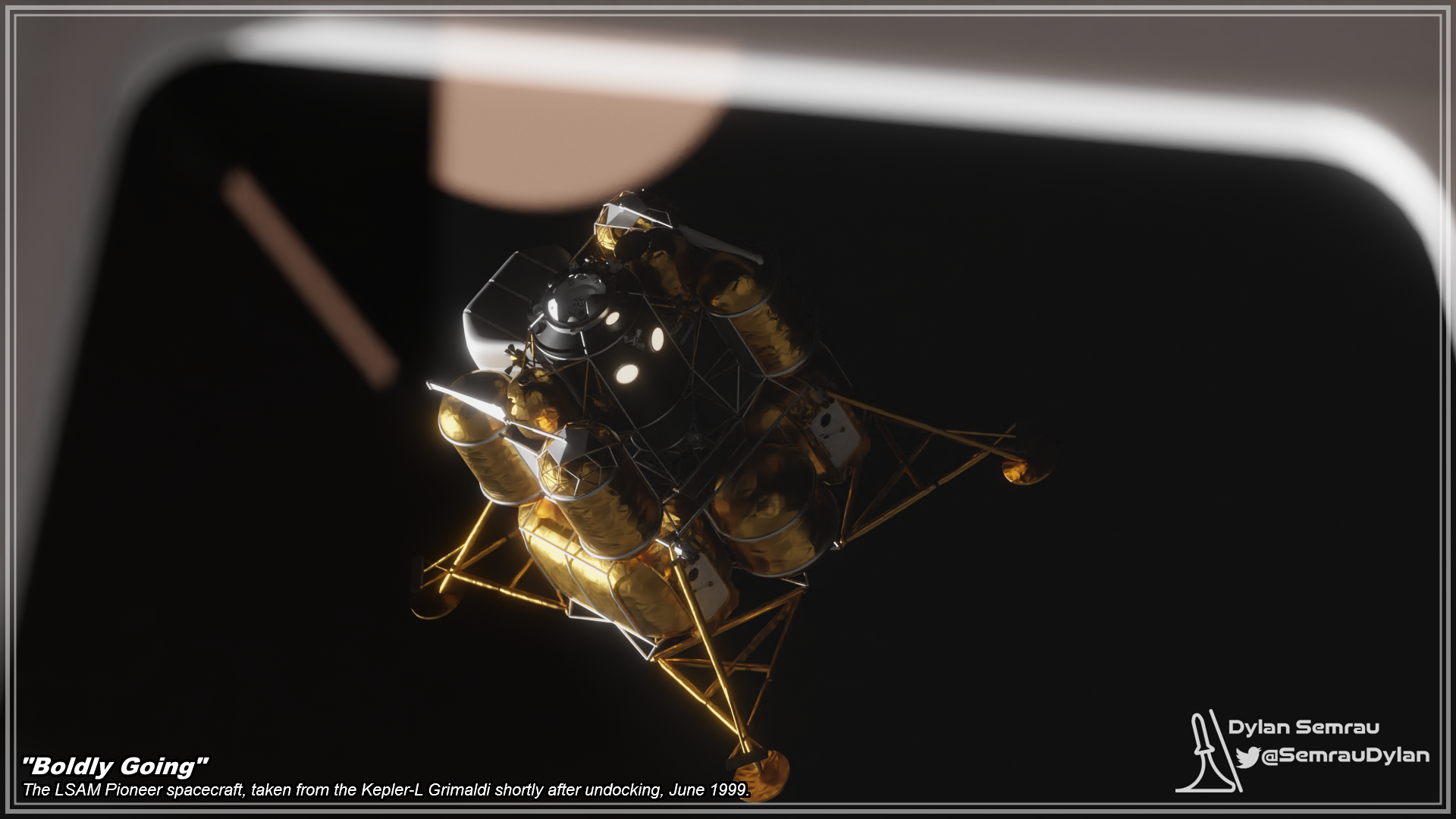

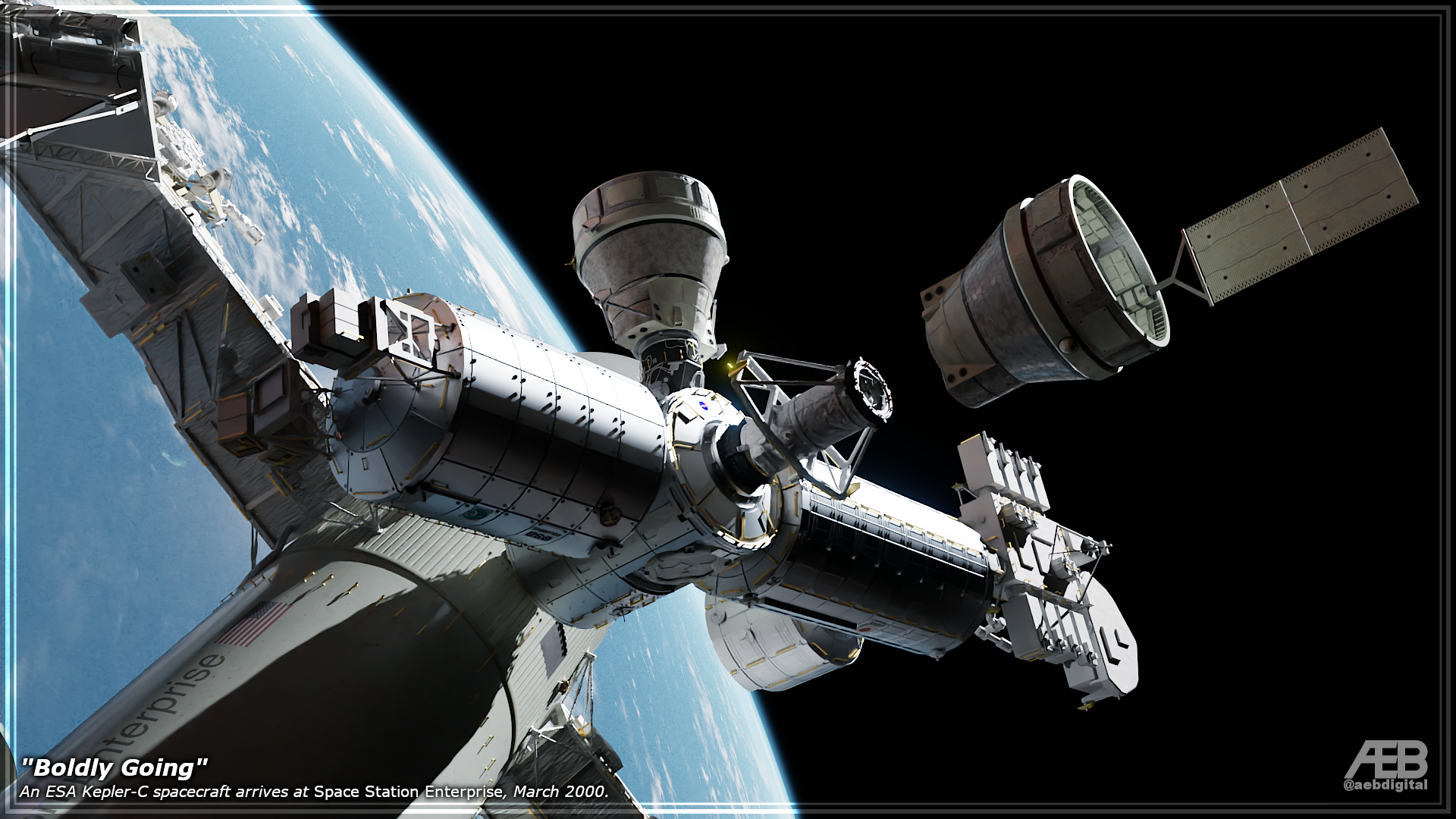

Kepler lifeboats and the Multi-Purpose Logistics Modules. The second Shuttle-II orbiter,

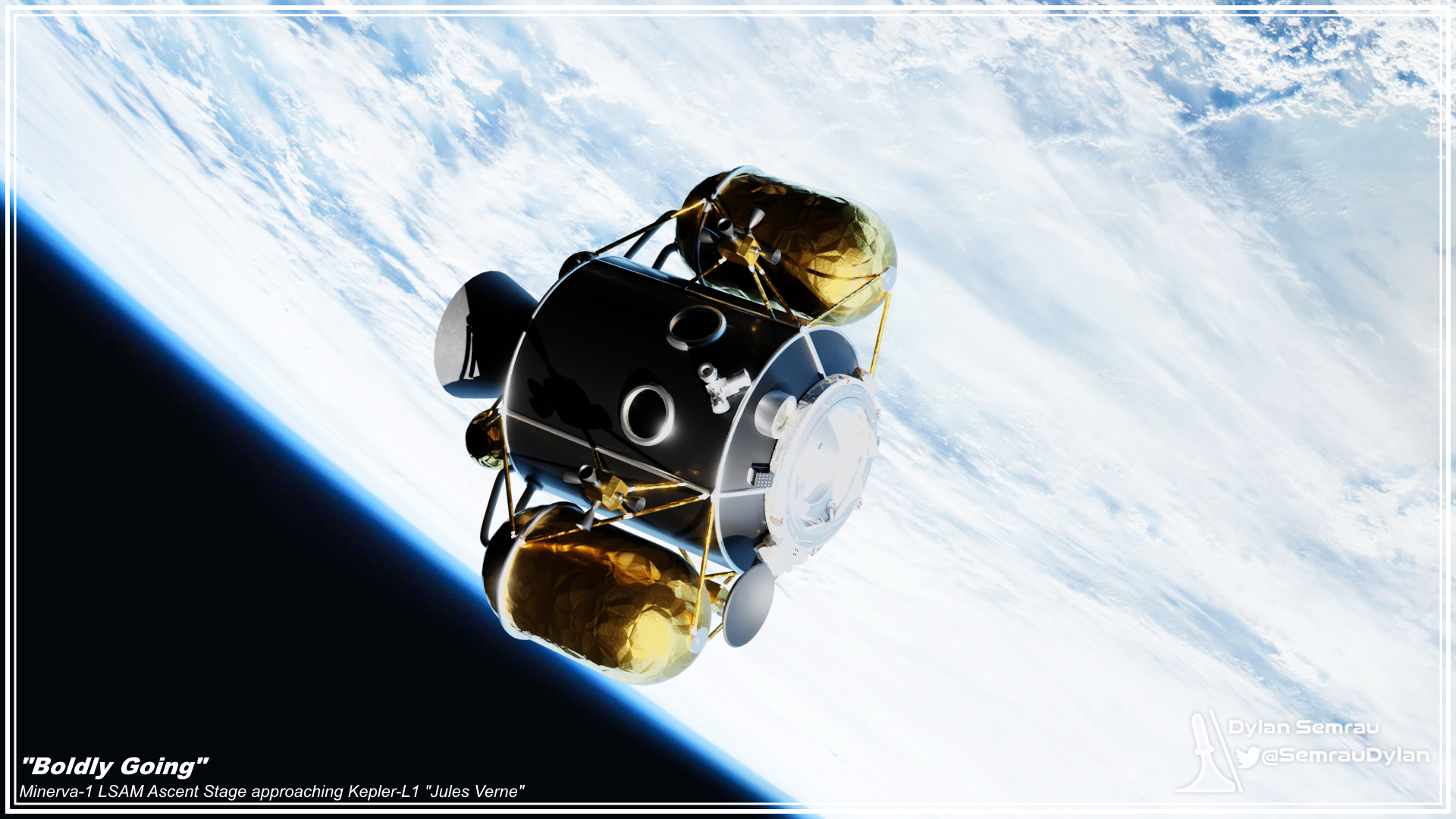

Freedom made her debut on STS-277 in March. The new orbiter carried a Kepler lifeboat in its cargo bay. Following procedures which had been developed over the years, Kepler no longer had to fly itself free of an arriving orbiter or make an independent rendezvous with the shuttle after departing station. Instead, by 1997 procedures had improved to use the station’s arm to pull the lifeboats out of a visiting orbiter’s bay and berth them to one of the station’s APAS ports. Not only did this save wear-and-tear and mision complexity, it ensured the ability to put Kepler lifeboats on APAS ports which were more difficult to access when approaching the station on independent flights. Once STS-277 docked as

Independence had on STS-276,

Freedom deployed its robotic arm under station and ground control and traded the Kepler lifeboat in its bay for one of the two which had stayed on station for the last six months. When it returned,

Freedom proved that Shuttle-II would have the same operational effectiveness which had already allowed the same set of four reusable Kepler-E lifeboats to support more than 50 rotations since 1995 with only minor refits and routine maintenance.

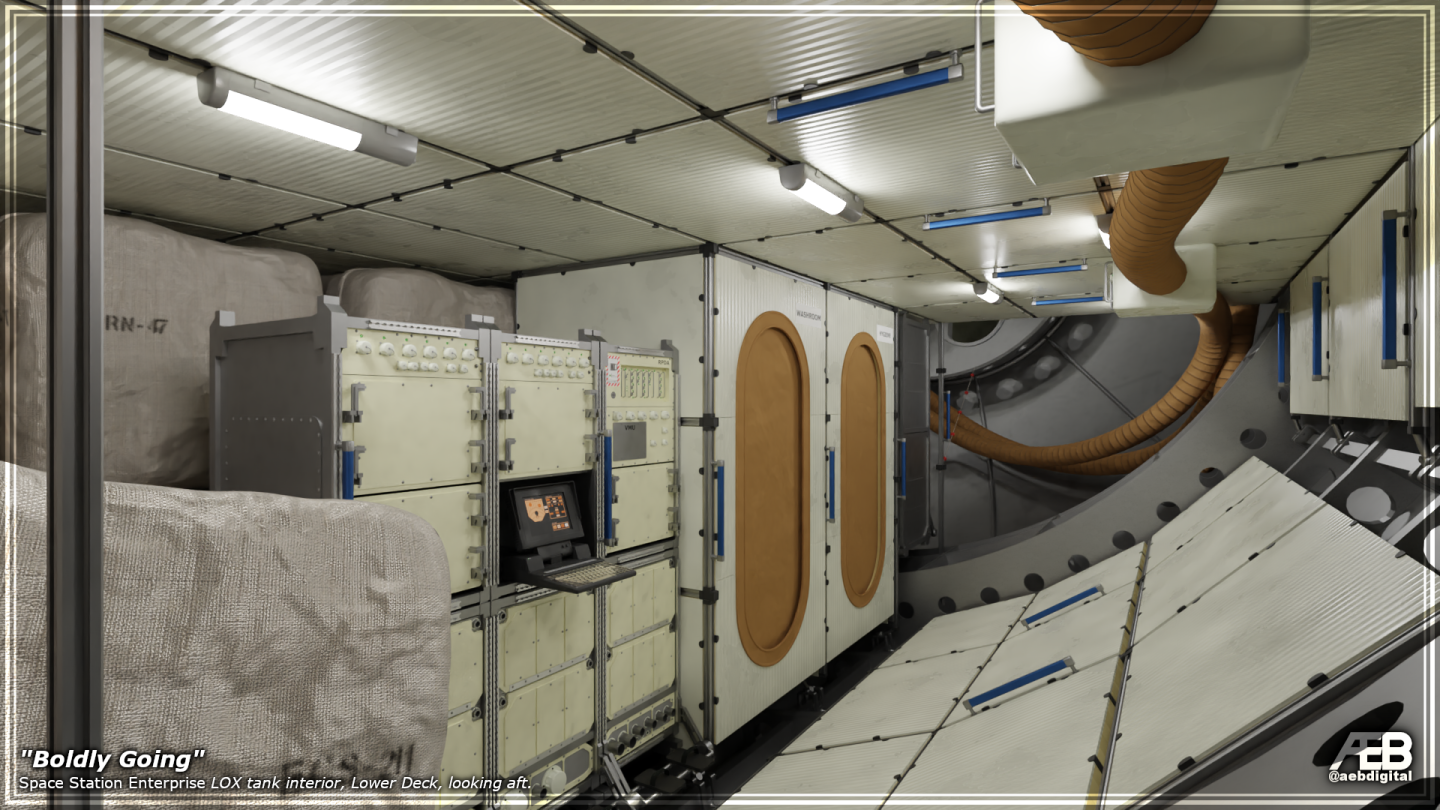

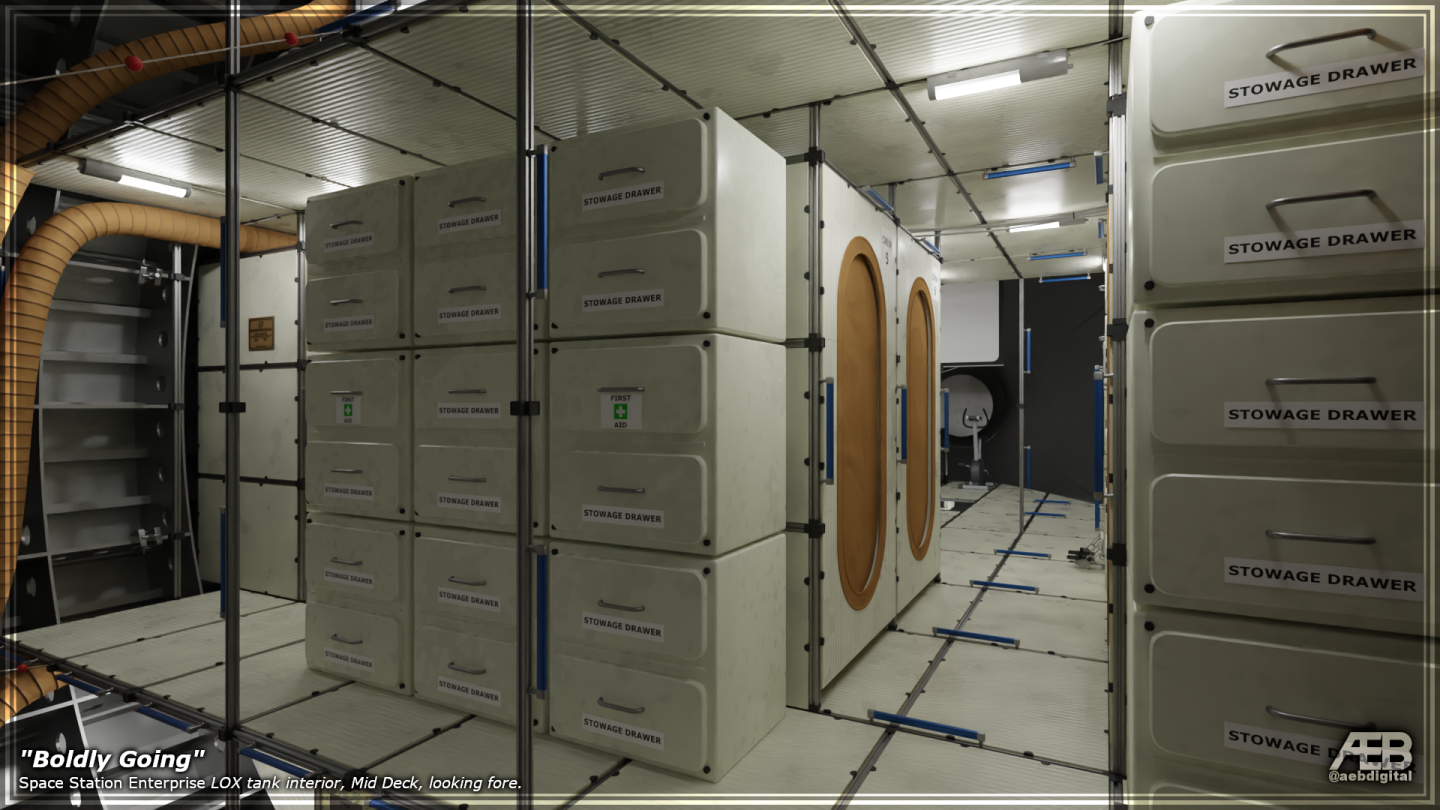

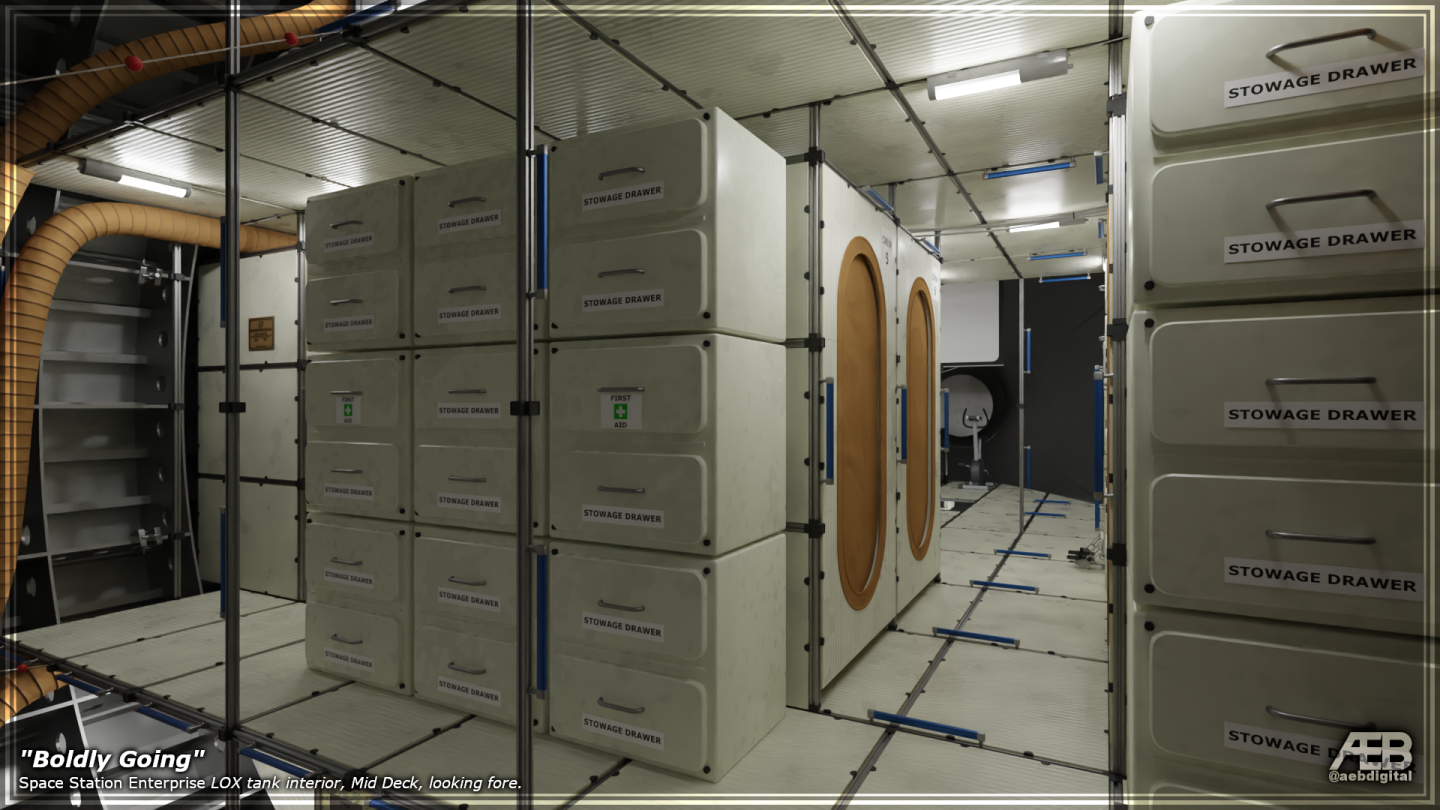

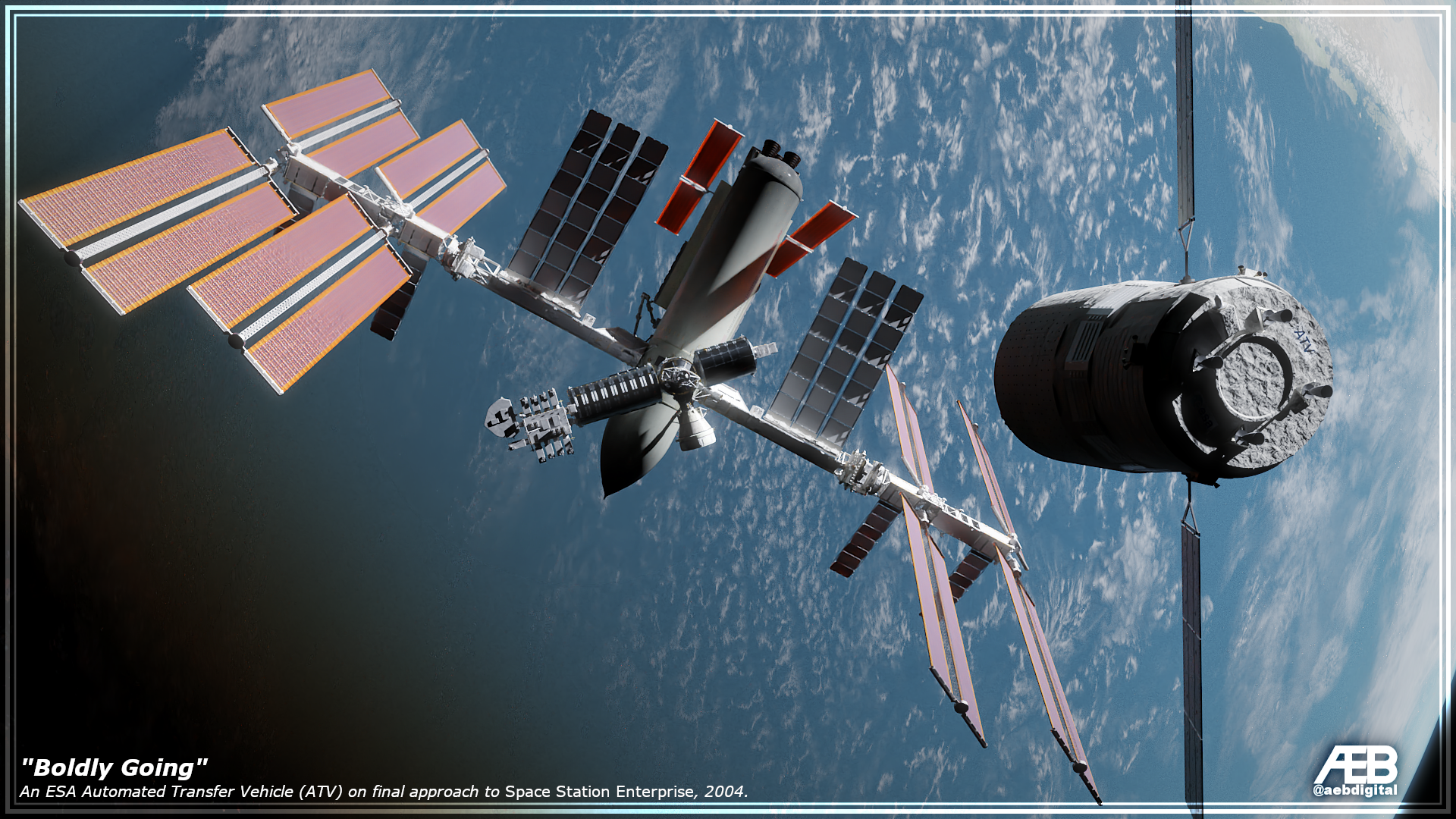

On STS-278 in August 2020, NASA tasked

Independence with a mission to demonstrate the other major support required for

Space Station Enterprise, by flying the legacy Multi-Purpose Logistics Module

Donatello. Though less exciting than the Kepler lifeboats or new modules flown to station, the stumpy can-shaped modules made up the backbone of the

Enterprise logistics pipeline. Like dozens of flights before it, STS-278 saw

Independence “carrying the mail” with tons of food, clothing, and routine scientific samples. With the module handed off to the station’s waiting arms, Shuttle-II proved it was ready to take on the challenges of supporting

Enterprise’s ongoing mission in orbit from the four remaining original Space Shuttles. The full support of all

Enterprise operations was demonstrated by a final mission, STS-279, which saw

Independence fly to station once more, this time with a fluid cargo and gas transfer transfer pallet in her bay. Though high-pressure nitrogen and oxygen tanks could simply be carried in the bay, transfer of hypergolic propellants for

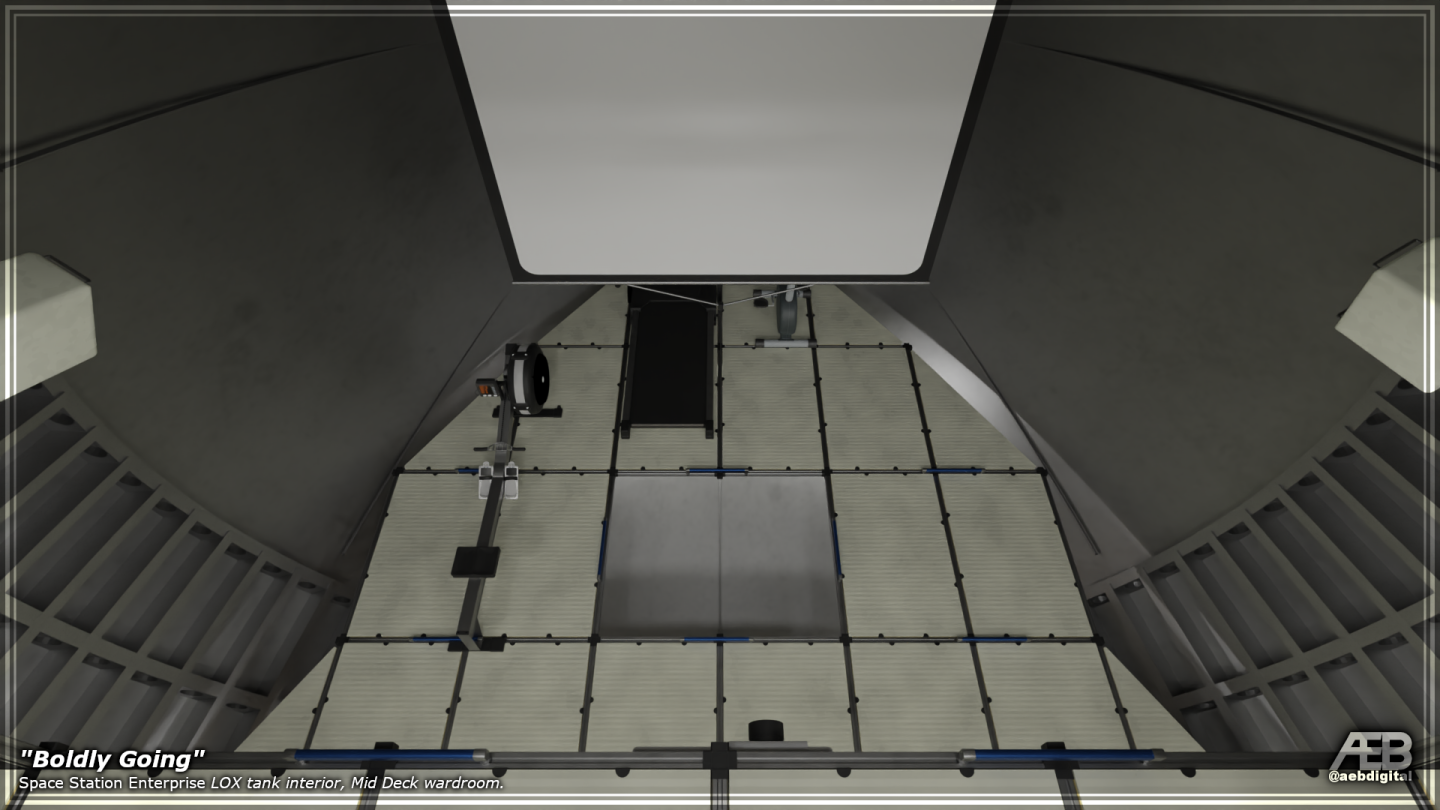

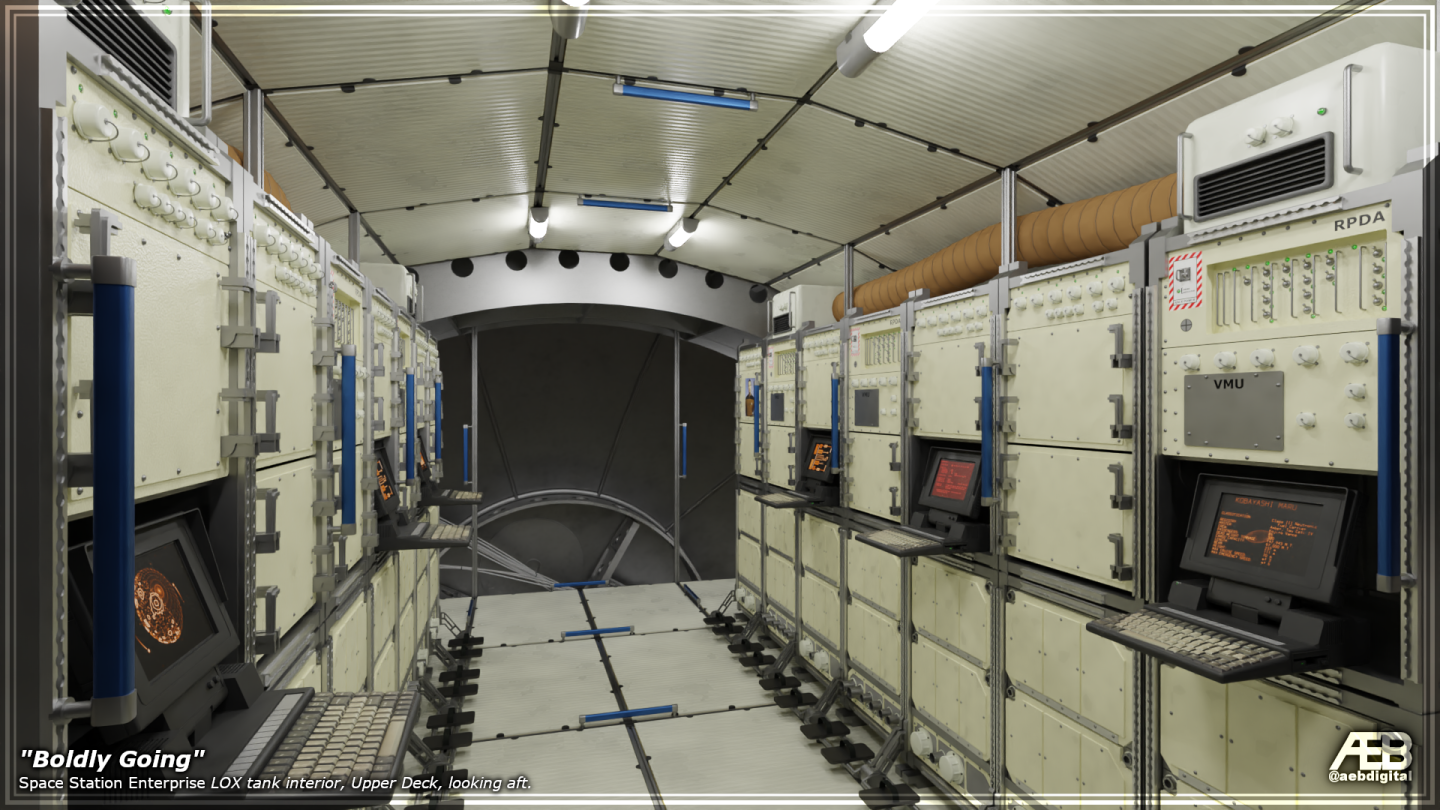

Enterprise and cryogenic oxygen and ethanol for the associated fleet of orbital vehicles was more complex.

On the previous-generation Space Shuttle, launching cryogenic oxygen to

Enterprise had required carrying a pallet of tanks inside the payload bay, tied into connections originally used for the Shuttle-Centaur “Death Star’ launches before the loss of

Discovery. For Shuttle-II, the process could be simplified by using cryogenic oxygen already stored for the orbiter’s own hydrogen/oxygen Orbital Maneuvering System on every mission. Plumbing to allow connecting to these supplies in flight had been designed into the new orbiter, and no new pad hookups were required. Thus, the only fluid and gas pallets needed for STS-279 and subsequent resupply flights were compressed nitrogen tanks and the tanks for room-temperature-storable hypergolic propellants and ethanol fuel, which could be filled prior to cargo bay close-out and left in-situ even during extended on-pad holds. Still, carrying fluids in the bay always raised the specter of leak concerns. During preparations for STS-279, there was an abundance of caution with the new fluids pallet and (ultimately spurious) warnings of leaks led to multiple aborts and scrubs. Eventually, NASA stood down the launch preparations for multiple days. Technicians reopened the orbiter’s payload bay to replace valve seals between the tank interconnects and the docking module. Finally, Shuttle-II knifed into the sky on a mission to top off the thirsty tanks of

Space Station Enterprise and all its associated vehicles. With two orbiters active and five successful flights under their belt, NASA’s Shuttle-II program managers began 2021 ready for the final challenge: crew.

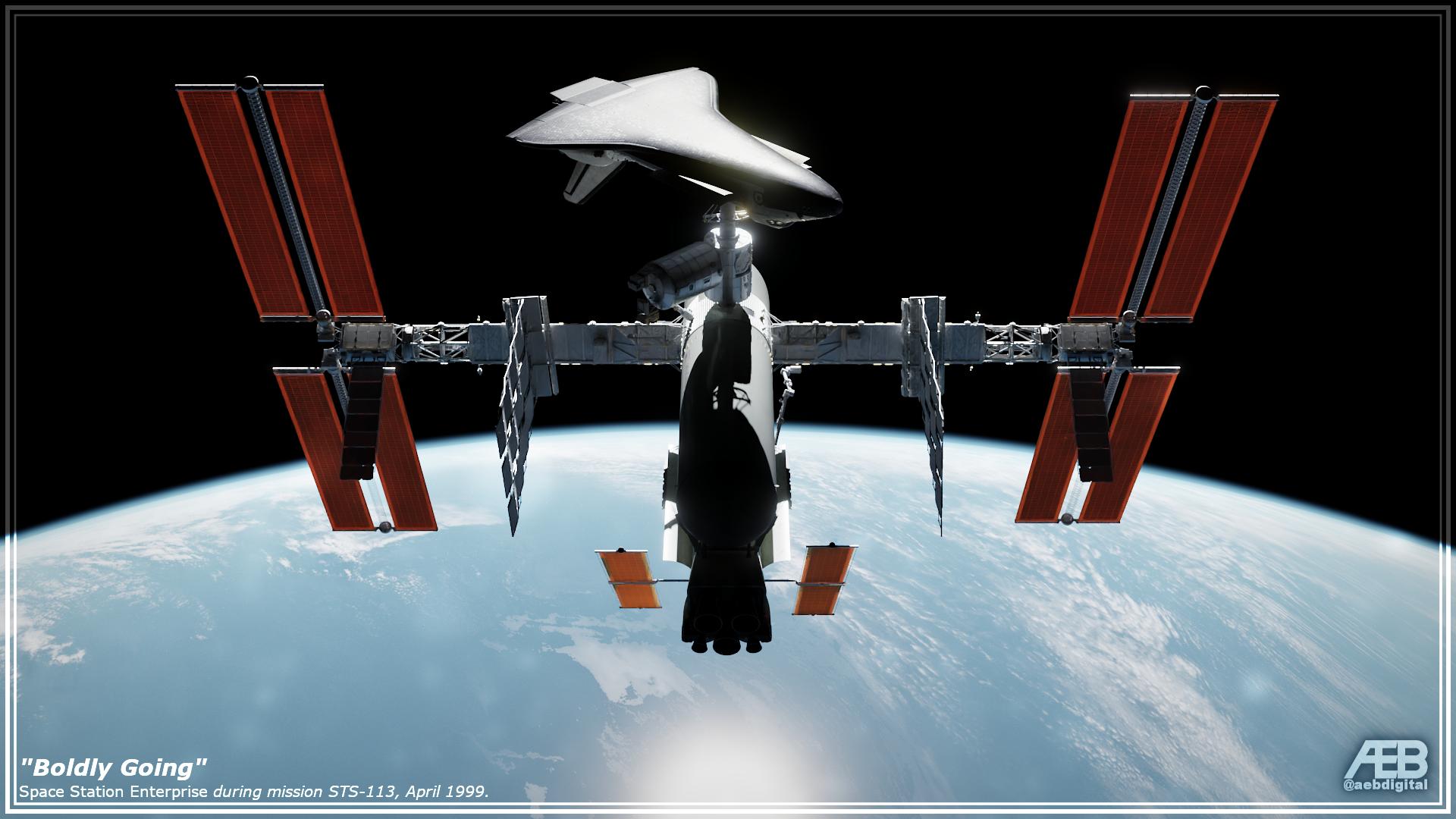

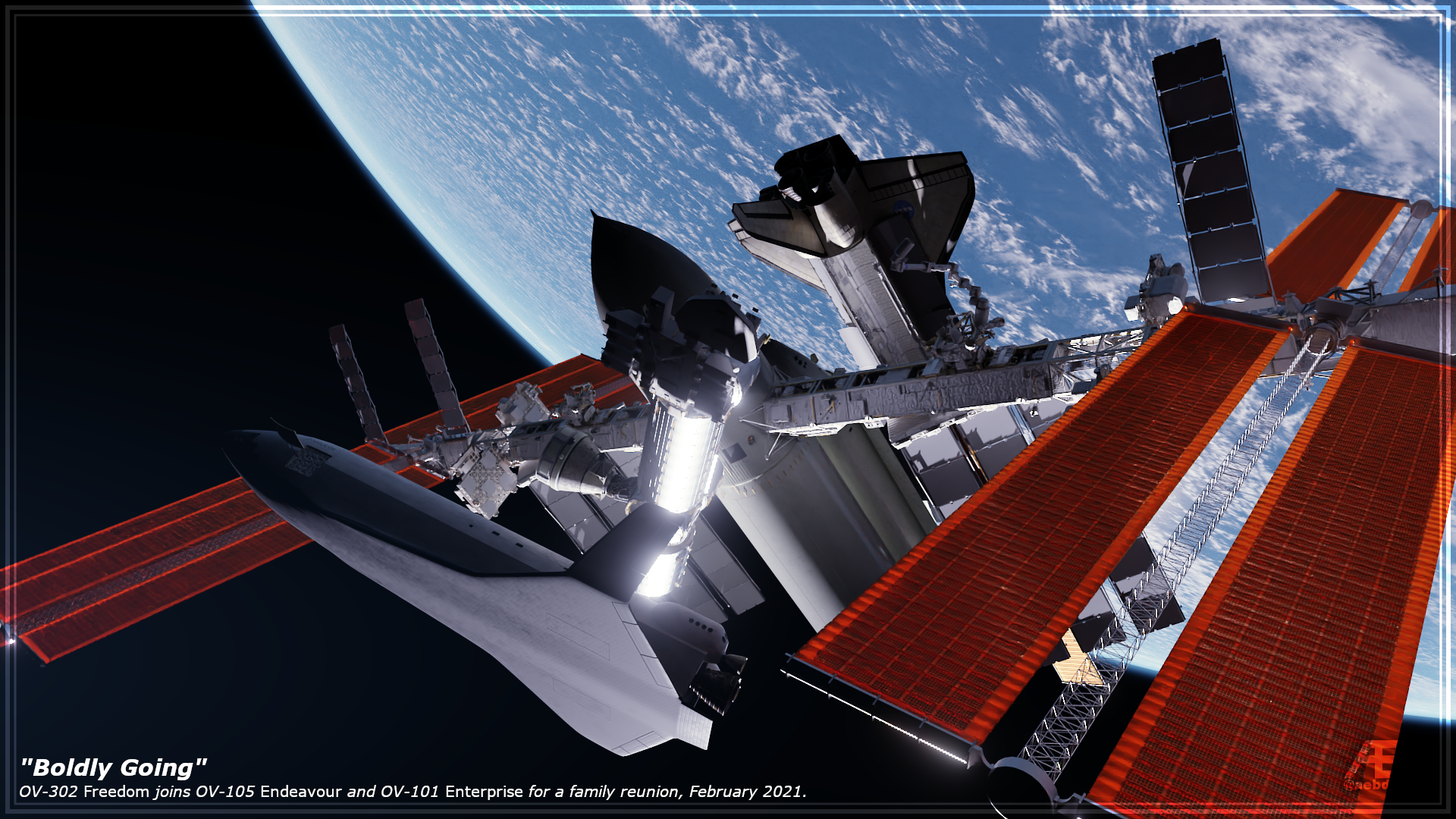

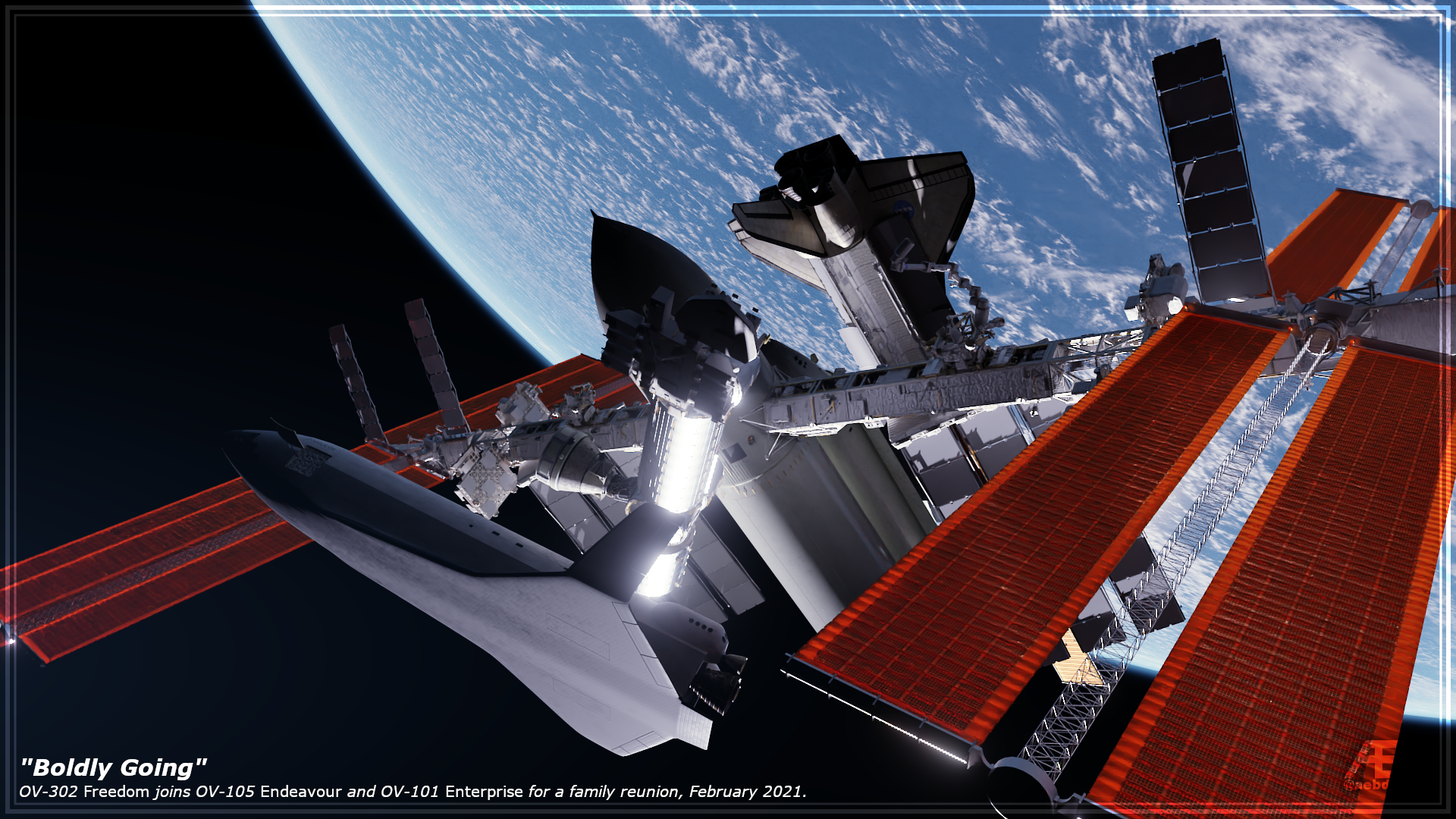

The NASA Public Affairs Office had big plans for STS-280. After a minor refit to incorporate early lessons from the first several flights, OV-302

Freedom was tapped to carry the new crew module to

Space Station Enterprise in February of 2021. To reduce risk, only the bare minimum crew would be aboard. Doug Hurley would be the spacecraft commander, while Bob Behnken would be the pilot. In order to ensure there were options for the crew’s safe return if problems with the new orbiter were encountered that made safe landing questionable, NASA arranged to have the previous shuttle mission, flown by

Endeavour, held at

Enterprise with spare seats to give Hurley and Behnken a backup ride home. For Public Affairs, this was a perfect opportunity. They begged Flight Operations to arrange for a fly-around of the station, conducted by a JAXA HTV which was held at station for a week past the original scheduled departure, to enable the remote camera systems aboard to capture the sight of three Shuttles on orbit together at the same time: the first orbiter (OV-101

Enterprise), the last of the first production run of orbiters (OV-105

Endeavour), and the first of the next generation of NASA crew spacecraft (OV-302

Freedom). With the

Enterprise Power Module solar arrays temporarily locked horizontally,

Endeavour was docked to the APAS adapter on Node 2’s zenith port, leaving the two sisters nearly touching with

Endeavour docked at the Node extending up from the old

Leonardo Laboratory module in

Enterprise’s payload bay. This left the more easily accessible Node 1 nadir port open for

Freedom. The resulting image of three sisters and the massive orbital complex they had spawned proved a spectacular capstone to the trouble-free debut of the new crew module. With data in hand from the first six orbital missions, NASA proudly certified the new Shuttle-II ready for regular service in June of 2021. At the same press conference, they also publicly confirmed the official hand-off between the two generations of shuttle. Though existing missions planned for the original orbiters were to be flown out, any new missions would be planned or transferred to the new Shuttle-II. As a block of mission numbers was reserved for the first flights of Shuttle-II, so too was a block reserved for the

last flights of the original orbiters. Thus, the final flight of the original series of space shuttles would be assigned to OV-104

Atlantis in late 2022 on STS-300.

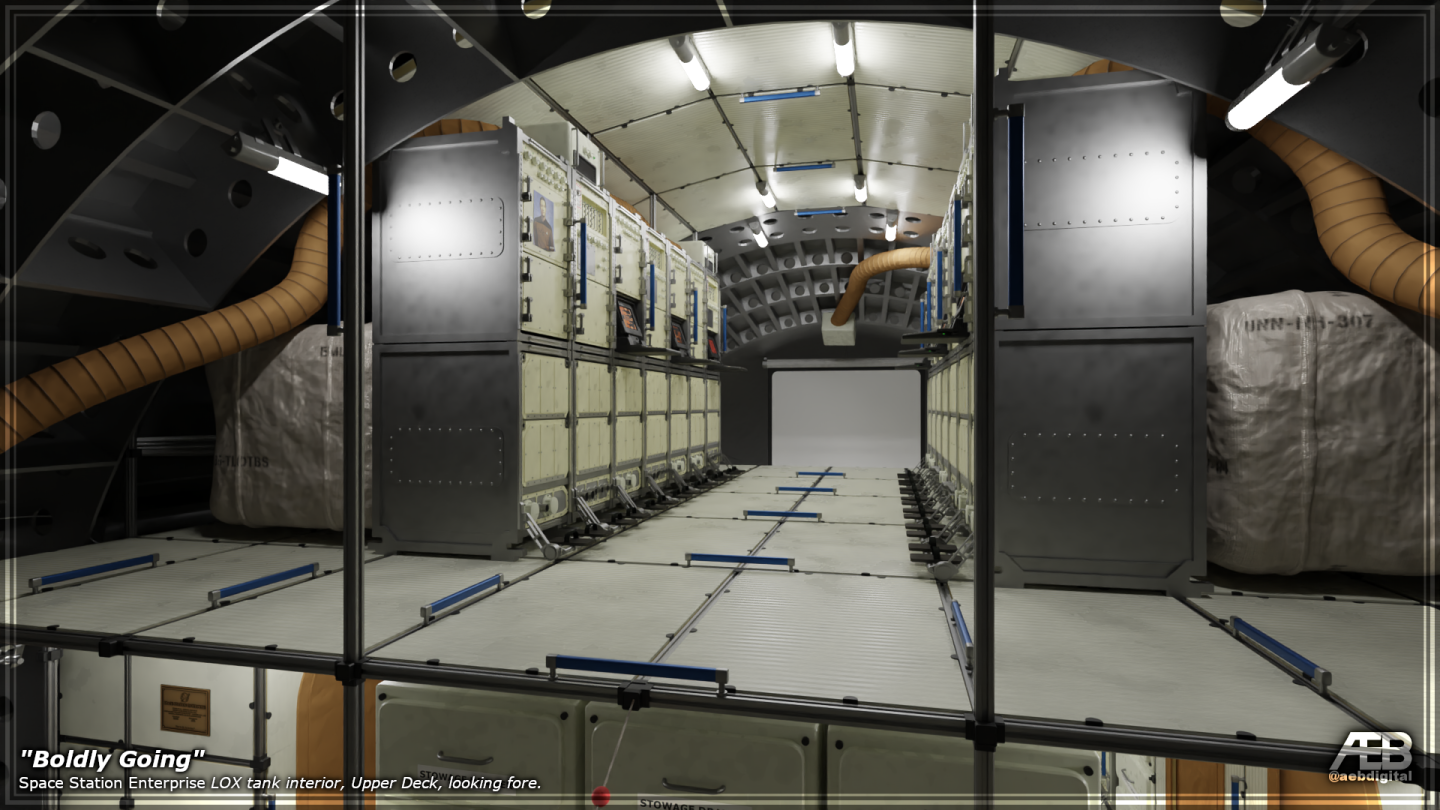

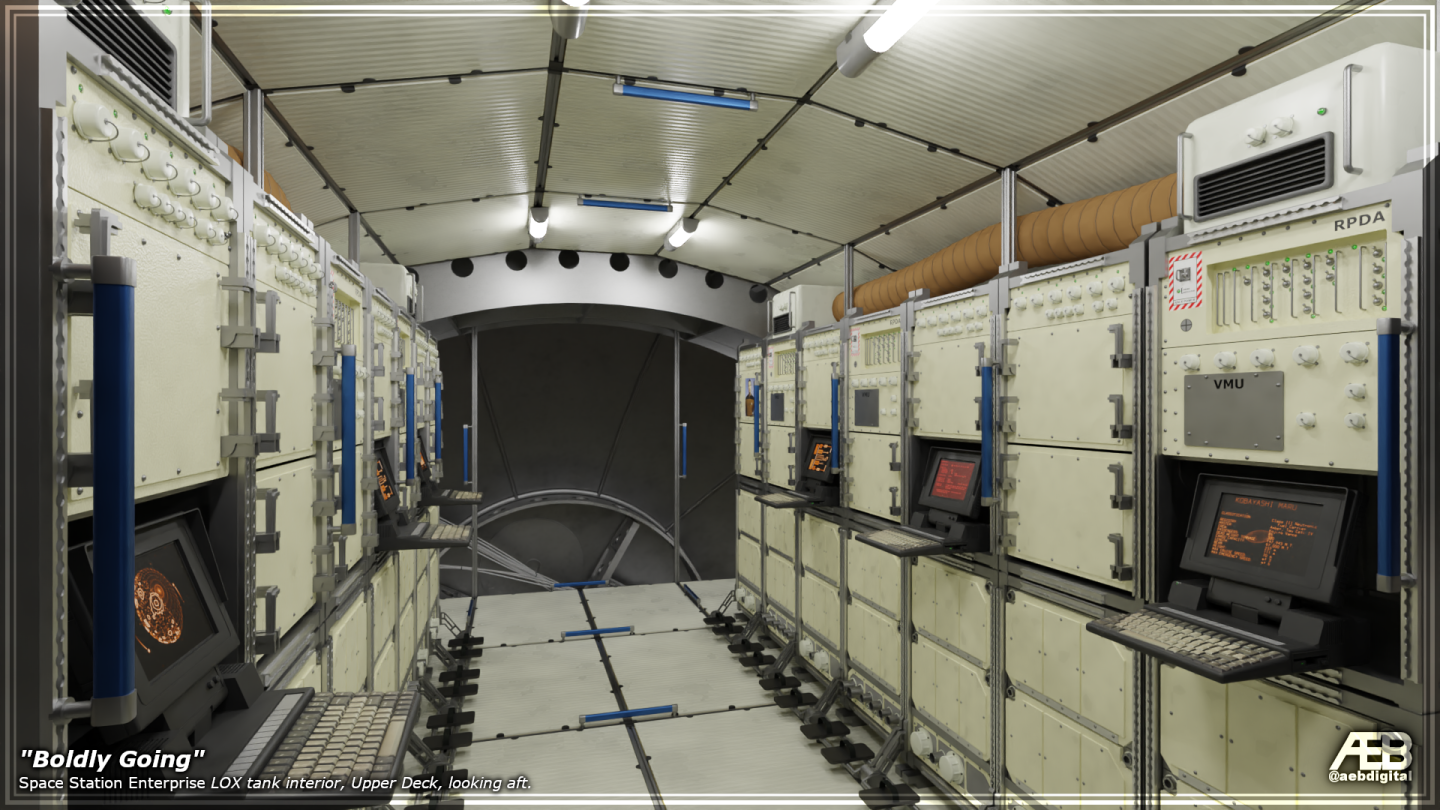

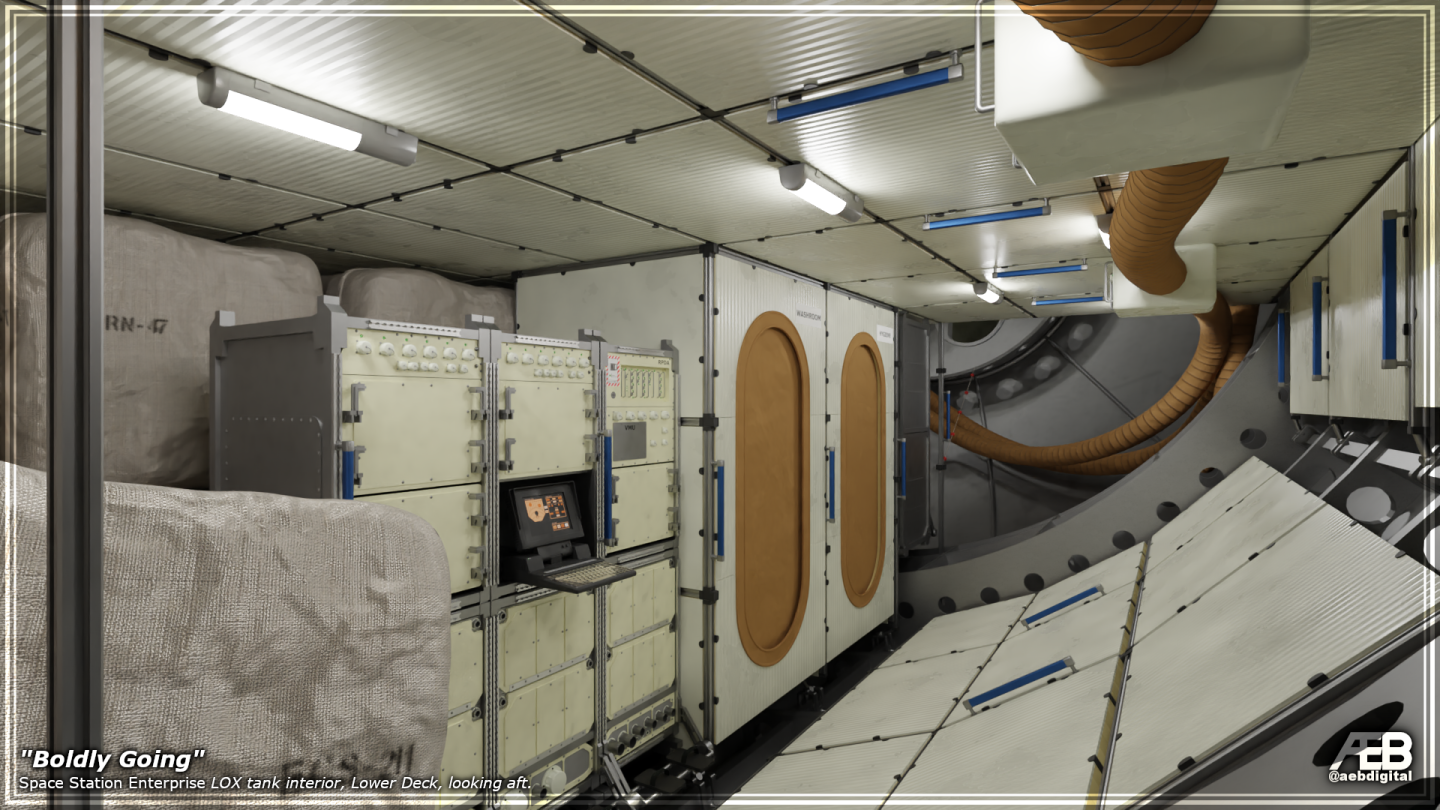

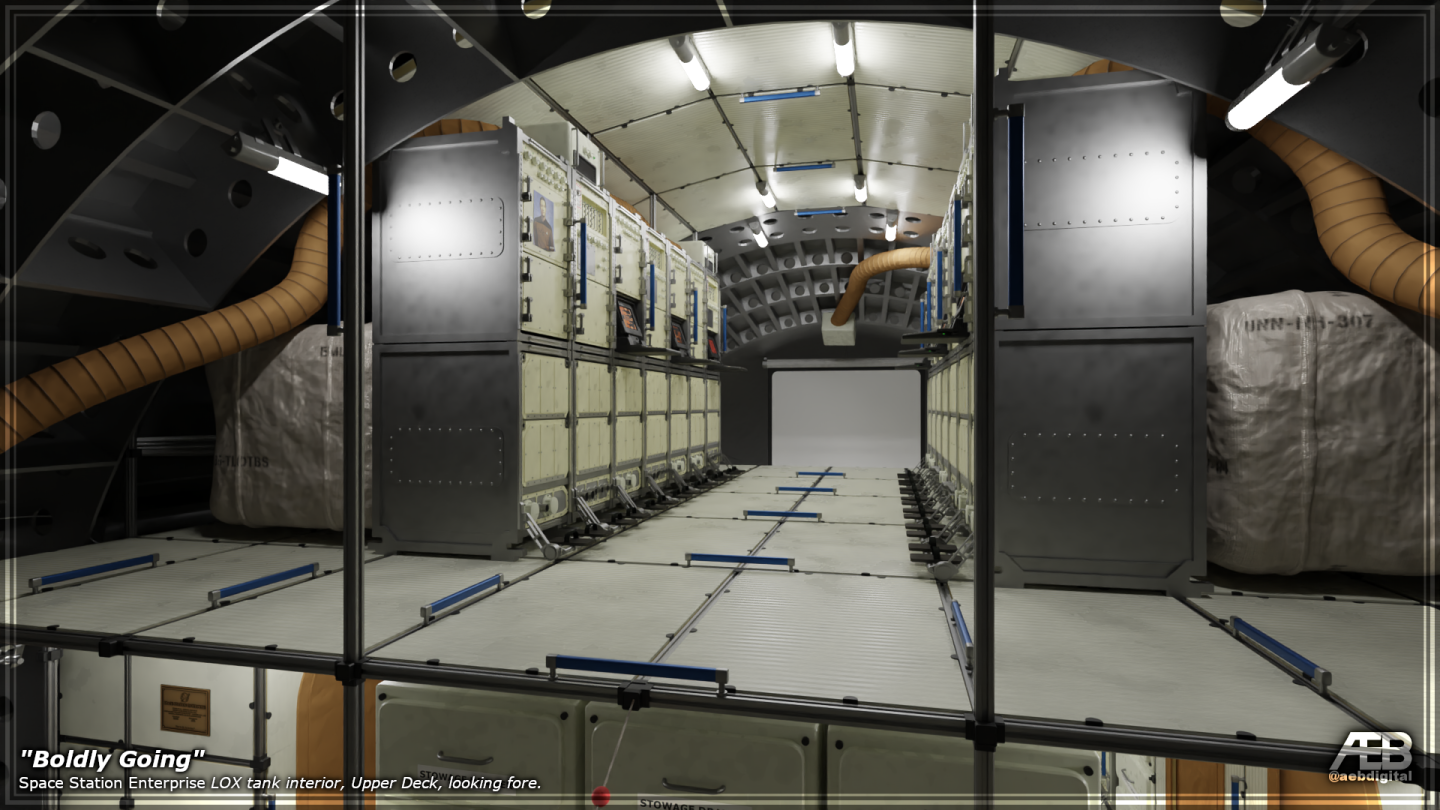

With the final flights of the original space shuttle orbiters, and the handover of orbital support to the new Shuttle-II fleet,

Enterprise is now the single longest continuing element in American and International crewed space infrastructure. Its capability to support massive and sustained human occupation in space, not to mention its tremendous scientific capability, more than justifies its continued center-stage position in the realm of human spaceflight.

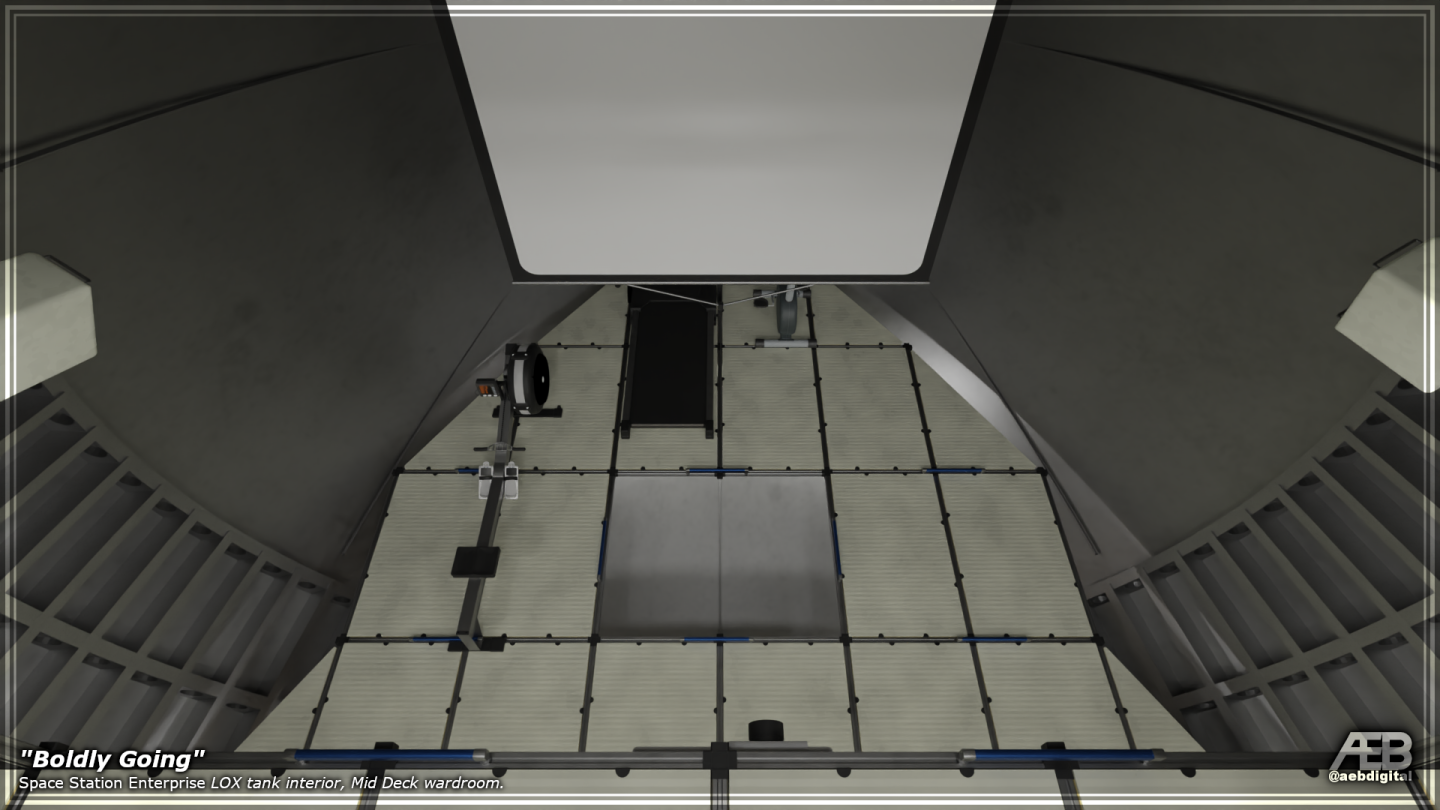

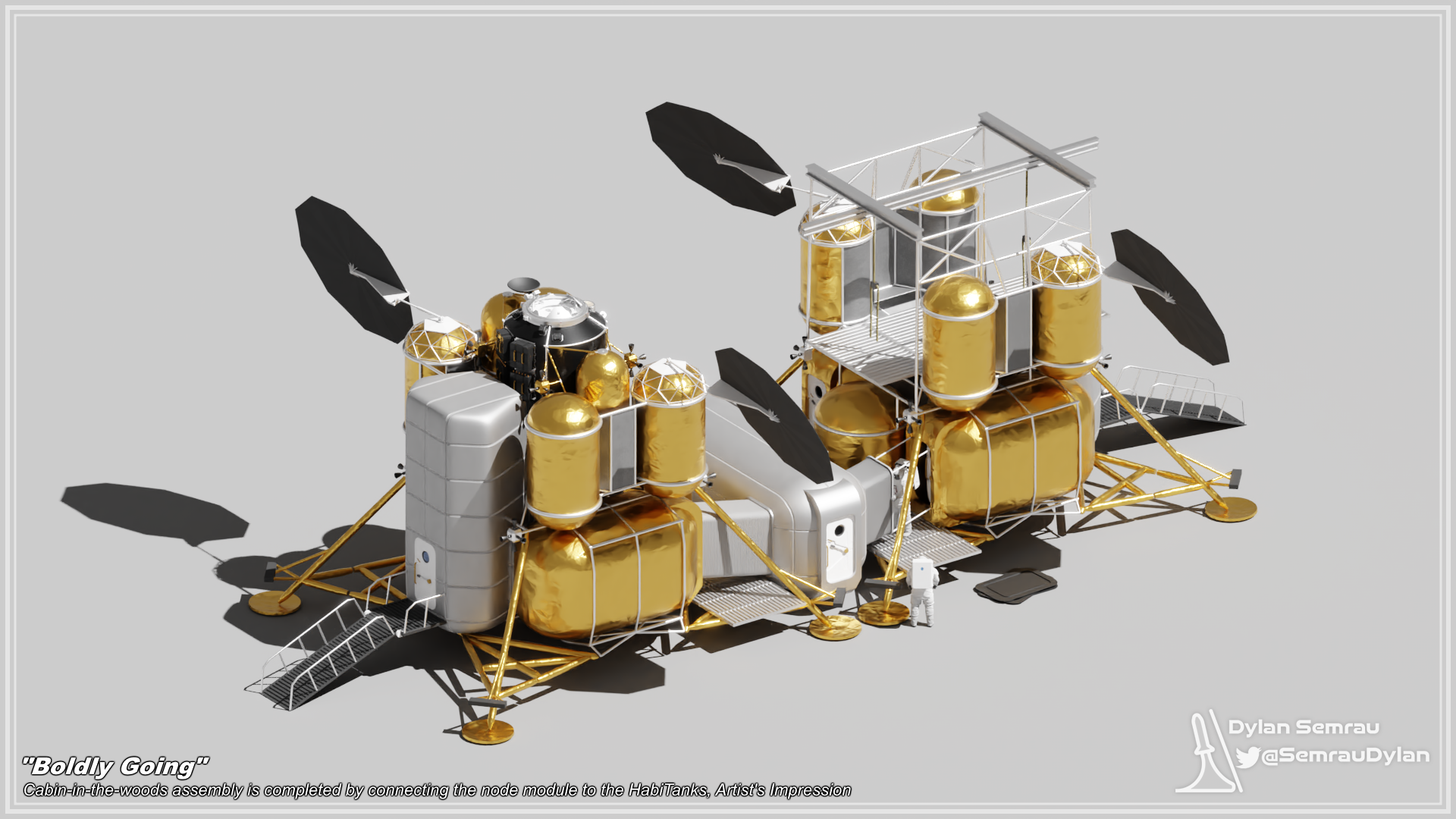

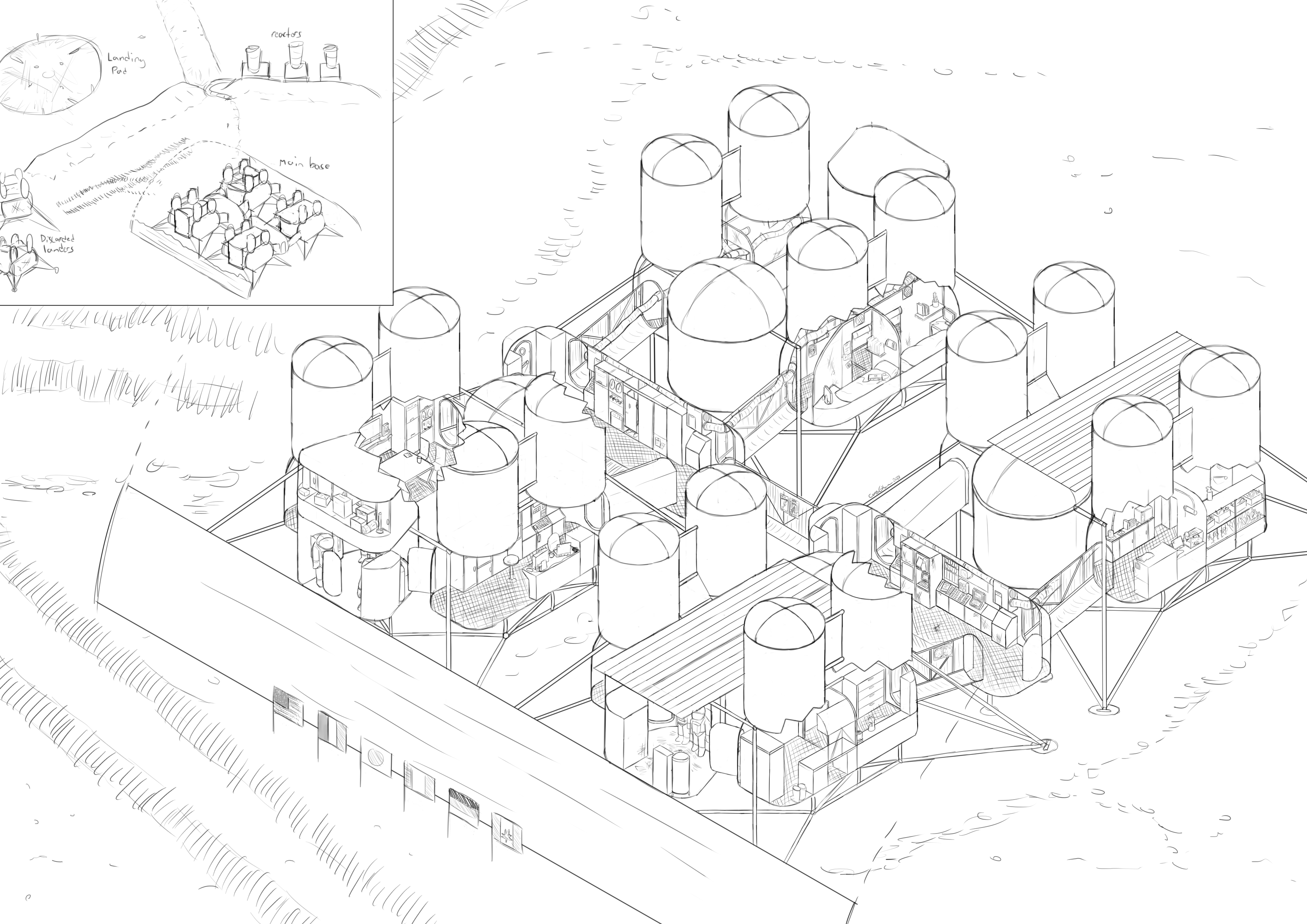

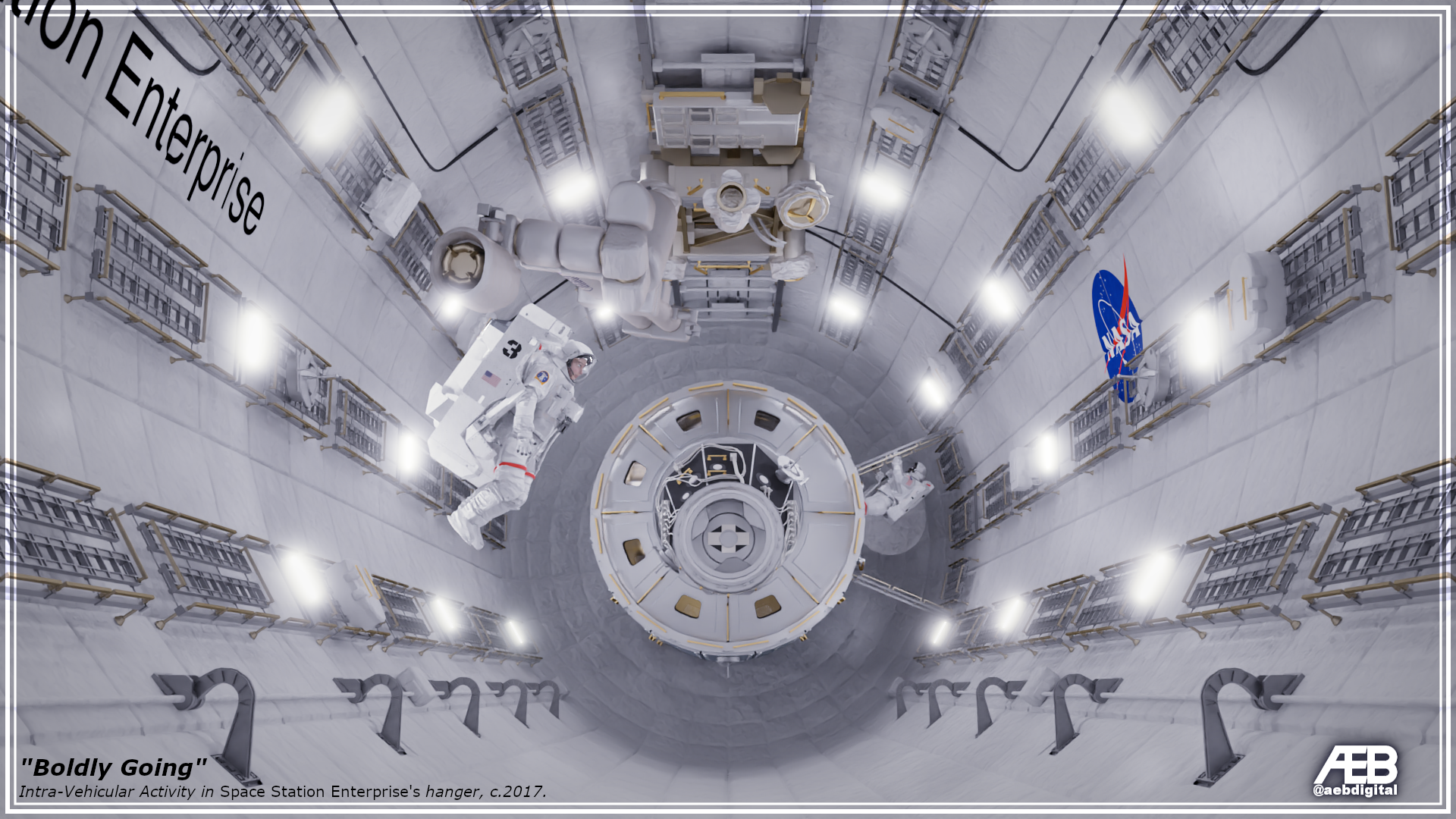

Enterprise’s STS-37R legacy occasionally presents weaknesses, like the narrow intertank “hamster tube” passages which frustrate distributing ISPR-enabled logistics and experiments around the periphery of the pressurized components on the station. Still, the station’s new hangar, and servicing capability it provides, is the center of

Enterprise’s support of the President’s renewed initiatives for space exploration. With the ability to service the new reusable

Diana variant of the

Conestoga lunar landers, the ramp-up of the Shackleton Crater lunar outpost from “Long Duration Stay” to “Permanently Crewed” status will provide work on orbit for many years to come. Within the next decade, the shuttle-turned-station may face an even greater challenge with on-orbit assembly and testing of the

Hōkū'ula Mars Transfer Vehicle if Congress upholds the President’s budget requests.

While her sisters eventually fulfilled their role as “space trucks” for the development of space infrastructure, OV-101

Enterprise has transcended her roots in every way by

becoming infrastructure. Once a ground-bound reject from the program’s early days,

Enterprise rose to the challenge when the lack of an American space station became a critical national deficit. Over decades of operation, her status as an ad-hoc expedient has turned into serving as a keystone for the ongoing development of humankind’s reach into the stellar frontier. In-space outfitting and servicing techniques developed for her construction and expansion were a testing-ground for techniques like Habitank conversion and reusability of in-space assets like

Galileo and

Conestoga. Her launch aboard STS-37R proved to be the pathfinder for the LRB-powered Shuttle-C, and she remains the most important destination in space for the new Shuttle-II fleet. The central role of

Space Station Enterprise in orbital science, American commercial research, and lunar & martian mission planning ensures

Enterprise will retain a role supporting missions no one has dreamt of before for years and possibly decades to come. As long as that continues, the program’s motto for the last forty years will remain true: “First to Fly, Last to Land.”

Authors’ Note: I swear, we forgot about the shuttle names in Armageddon until after we had these names picked.

[1] Here is the math we worked through. STS-131 closed out CY2001 ITTL. There were then nine flights each year in 2002 and 2003 to finish building out

Space Station Enterprise. Given this total (149 flights at the end of 2003), we looked forward over the next nearly two decades. There would be four or five conventional shuttle flights per year (covering lifeboat rotation and logistics, as well as occasional show-the-flag flights to MIR-II). Furthermore, there are at least two Shuttle-C launches each year to deliver crew to the moon, and there are, in the 2004-2017 period, another nine or so cargo flights, each needing two launches for site establishment and base buildout. With a few additional flights sprinkled in for the DoD and JPL, we came to the conclusion that there would be on average about

NINE STS-numbered launches per year. Added to the above total, and when NASA manifests the Shuttle-II test flights in 2016, the first batch available that is near a nice round number starts on STS-275. With the lunar base moving into operations and sustainment instead of expansion, the 2018-2022 period sees a slightly lower number of flights (averaging about eight per year), which is why STS-300 is selected as the number for the last original orbiter flight.

Render by:

@nixonshead (

AEB Digital on Twitter)

Patch by:

Disco Slelge