Starting an internal combustion engine. Check fuel, oil, water if needed, turn a switch press a button Brmmm Brmmm off you go.

Starting a Steamer. Check fuel, oil, water, crank a handle to get the fuel up to pressure so it gets to the burners or injectors press a button or light a blow torch Wummff the burner lights then crank a handle to get water into boiler and wait whilst pressure builds up frantically tapping the pressure guage willing it to go past working pressure. When its finally up to pressure (10 to 15 minutes for a flash boiler anything up to an hour for a Firetube boiler) off you go but you will need a boilerman to keep an eye on the water, Flash boilers were prone to running dry very quickly and when that happens its back to the boilersmiths.

Despite what many people think Tanks spend a lot of time with the engine off waiting for orders to do something. Internal combustion engine no problem (lots of tanks have a small aux engine to keep the battery topped up) steam boilers dont like the hot and cold cycle once its hot you need to keep it hot till the end of the working day.

You will need a condenser which is a big thing much bigger than a radiator especially if its an air condenser.

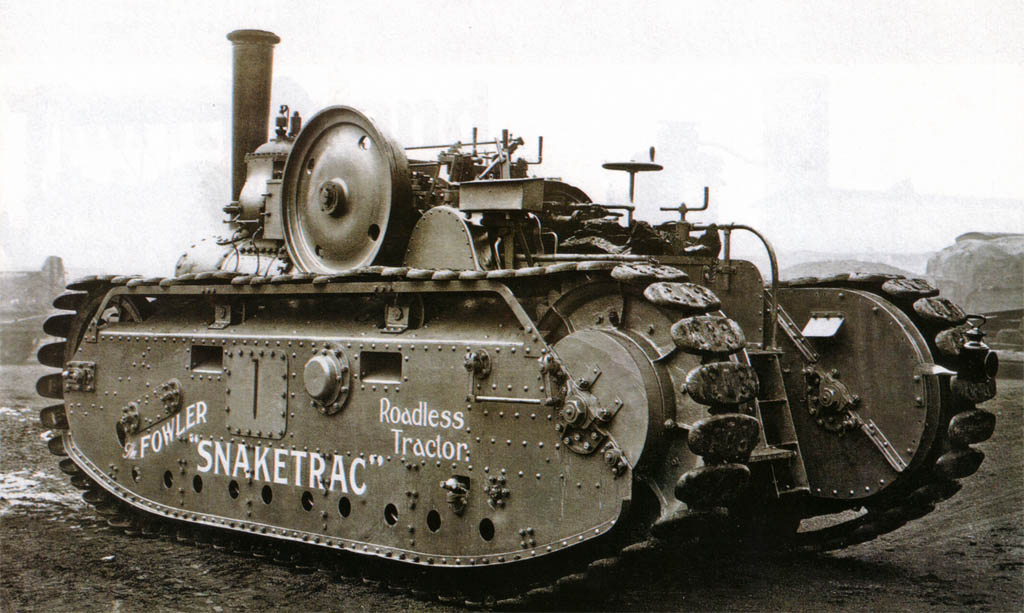

Its doable but its going to be BIG tank.